Общий каталог Sumitomo 2018 - 2019 - страница 455

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

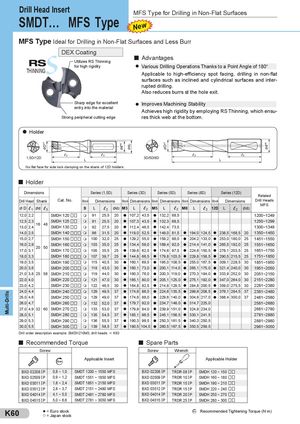

Multi-Drills ØDh7 Ødh6 Ød2 ØDh7 Ødh6 Drill Head Insert MFS Type for Drilling in Non-Flat Surfaces SMDT… MFS Type New MFS Type Ideal for Drilling in Non-Flat Surfaces and Less Burr DEX Coating Utilizes RS Thinning Advantages for high rigidity Various Drilling Operations Thanks to a Point Angle of 180° THINNING Applicable to high-efficiency spot facing, drilling in non-flat surfaces such as inclined and cylindrical surfaces and inter- rupted drilling. Also reduces burrs st the hole exit. Sharp edge for excellent Improves Machining Stability entry into the material Achieves high rigidity by employing RS Thinning, which ensu- Strong peripheral cutting edge res thick web at the bottom. Holder 1,5D/12D l2 l3L 3D/5D/8D l2 l3L No flat face for side lock clamping on the shank of 12D holders. Holder Dimensions Series (1,5D) Series (3D) Series (5D) Series (8D) Series (12D) Related Drill Head Shank Cat. No. Stock Dimensions Stock Dimensions Stock Dimensions Stock Dimensions Stock Dimensions Drill Heads ØD l1 Ød l3 S L l2 Ød2 M3 L l2 M5 L l2 M8 L l2 12D L l2 Ød2 MFS 12,0 2,2 SMDH 120 m 91 25,5 20 107,2 43,5 132,2 68,5 1200~1249 12,5 2,3 SMDH 125 m 91 25,5 20 107,3 43,5 132,3 68,5 1250~1299 16 4813,0 2,4SMDH 130 m 92 27,5 20 112,4 46,5 142,4 73,5 1300~1349 14,0 2,5 SMDH 140 m 96 31,5 20 119,0 52,5 149,0 81,5 194,0 124,5 238,5 168,5 20 1350~1450 15,0 2,7 SMDH 150 m 100 32,0 25 129,2 55,0 159,2 86,0 204,2 133,0 253,0 180,0 25 1451~1550 16,0 2,9 SMDH 160 m 103 35,0 25 134,4 59,0 169,4 92,0 214,4 141,0 265,5 192,0 25 1551~1650 20 5017,0 3,1SMDH 170 m 105 35,5 25 139,6 62,5 174,6 97,5 224,6 150,5 278,1 203,5 25 1651~1750 18,0 3,3 SMDH 180 m 107 39,7 25 144,8 66,5 179,8 103,5 229,8 158,5 290,5 215,5 25 1751~1850 19,0 3,5 SMDH 190 m 115 40,5 30 160,1 69,5 195,0 108,5 255,0 167,5 309,1 228,5 30 1851~1950 20,0 3,6 SMDH 200 m 118 43,0 30 160,1 73,0 200,1 114,0 265,1 175,0 321,4 240,0 30 1951~2050 21,0 3,8 25 56 SMDH 210 m 119 44,0 30 160,3 76,0 200,3 119,0 270,3 184,0 333,9 252,0 30 2051~2150 22,0 4,0 SMDH 220 m 121 47,0 30 165,1 80,0 205,1 125,0 275,1 192,0 347,0 264,0 30 2151~2280 23,0 4,2 SMDH 230 m 122 46,5 30 164,8 82,5 214,8 129,5 284,8 200,5 359,0 275,5 30 2281~2380 24,0 4,4 SMDH 240 m 129 49,5 37 174,6 86,5 224,6 135,5 299,6 208,5 376,1 284,5 37 2381~2480 25,0 4,6 SMDH 250 m 129 49,0 37 174,6 88,0 229,6 140,0 304,6 217,0 388,4 300,0 37 2481~2580 26,0 4,7 SMDH 260 m 132 52,0 37 179,7 92,0 234,7 146,0 314,7 225,0 2581~2680 27,0 4,9 32 60 SMDH 270 m 133 53,0 37 179,9 94,0 239,9 151,0 324,9 234,0 2681~2780 28,0 5,1 SMDH 280 m 135 54,5 37 185,1 96,5 245,1 156,5 330,1 241,5 2781~2880 29,0 5,3 SMDH 290 m 136 55,5 37 190,3 99,5 250,3 161,5 340,3 250,5 2881~2980 30,0 5,5 SMDH 300 m 139 58,5 37 190,5 104,5 260,5 167,5 350,5 259,5 2981~3050 Drill order description example: SMDH210M3, drill heads a K63 1 Recommended Torque Spare Parts Screw Screw Wrench Applicable Insert Applicable Holder BXD 02208 ΙP 0,8 ~ 1,0 SMDT 1200 ~ 1550 MFS BXD 02208 ΙP TRDR 08 ΙP SMDH 120 ~ 150 BXD 02509 ΙP 0,9 ~ 1,2 SMDT 1551 ~ 1850 MFS BXD 02509 ΙP TRDR 10 ΙP SMDH 160 ~ 180 BXD 03011 ΙP 1,8 ~ 2,4 SMDT 1851 ~ 2150 MFS BXD 03011 ΙP TRDR 15 ΙP SMDH 190 ~ 210 BXD 03512 ΙP 2,8 ~ 3,7 SMDT 2151 ~ 2480 MFS BXD 03512 ΙP TRDR 15 ΙP SMDH 220 ~ 240 BXD 04014 ΙP 4,1 ~ 5,5 SMDT 2481 ~ 2780 MFS BXD 04014 ΙP TRDR 20 ΙP SMDH 250 ~ 270 BXD 04515 ΙP 5,0 ~ 6,6 SMDT 2781 ~ 3050 MFS BXD 04515 ΙP TRDR 25 ΙP SMDH 280 ~ 300 K60 l = Euro stock= Japan stock Recommended Tightening Torque (N·m)

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части