Общий каталог Sumitomo 2018 - 2019 - страница 44

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

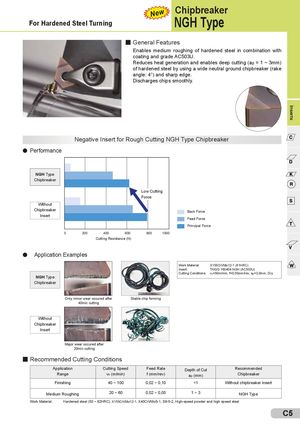

Inserts New Chipbreaker For Hardened Steel Turning NGH Type General Features Enables medium roughing of hardened steel in combination with coating and grade AC503U. Reduces heat generation and enables deep cutting (ap = 1 ~ 3mm) of hardened steel by using a wide neutral ground chipbreaker (rake angle: 4°) and sharp edge. Discharges chips smoothly. Negative Insert for Rough Cutting NGH Type Chipbreaker Performance NGH Type Chipbreaker Low Cutting Force Without Chipbreaker Back Force Insert Feed Force Principal Force 0 200 400 600 800 1000 Cutting Resistance (N) Application Examples Work Material: X155CrVMo12-1 (61HRC) Insert: TNGG 160404 NGH (AC503U) Cutting Conditions: vc=50m/min, f=0,05mm/rev, ap=3,0mm, Dry NGH Type Chipbreaker Only minor wear occured after Stable chip forming 40min cutting Without Chipbreaker Insert Major wear occured after 20min cutting Recommended Cutting Conditions Application Cutting Speed Feed Rate Depth of Cut Recommended Range vc (m/min) f (mm/rev) ap (mm) Chipbreaker Finishing 40 ~ 100 0,02 ~ 0,10 <1 Without chipbreaker insert Medium Roughing 20 ~ 60 0,02 ~ 0,05 1~3 NGH Type Work Material: Hardened steel (50 ~ 62HRC), X155CrVMo12-1, X40CrVMo5-1, S6-5-2, High-speed powder and high speed steel C5

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части