Общий каталог Sumitomo 2018 - 2019 - страница 399

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

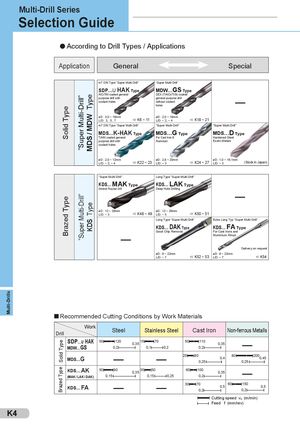

Multi-Drills Solid TypeBrazed Type Solid TypeBrazed Type ”Super Multi-Drill””Super Multi-Drill” TypeMDS / MDWTypeKDS Multi-Drill Series Selection Guide According to Drill Types / Applications Application General Special m7 DIN Type ”Super Multi-Drill” ”Super Multi-Drill” SDP…U HAK Type MDW…GS Type AlCrTiN coated general DEX (TiAlCr/TiSi) coated purpose drill with general purpose drillcoolant holeswithout coolantholes — øD : 3,0 ~ 16mm øD : 2,0 ~ 16mm L/D: 3, 5, 7 a K6 ~ 11 L/D: ~ 2, ~ 4 a K18 ~ 21 m7 DIN Type ”Super Multi-Drill” ”Super Multi-Drill” ”Super Multi-Drill” MDS…K-HAK Type MDS…G Type MDS…D Type TiAlN coated general For Cast Iron & Hardened Steel purpose drill with Aluminum Exotic Metals coolant holes øD : 2,0 ~ 12mm øD : 2,8 ~ 20mm øD : 1,0 ~ 16,1mm L/D: ~ 2, ~ 4 a K22 ~ 23 L/D: ~ 3 a K24 ~ 27 L/D: ~ 3 (Stock in Japan) ”Super Multi-Drill” Long Type ”Super Multi-Drill” KDS… MAK Type KDS… LAK Type General Purpose Drill Deep Hole Drilling — øD : 12 ~ 26mm øD : 12 ~ 26mm L/D: ~ 3 a K48 ~ 49 L/D: ~ 5 a K50 ~ 51 Long Type ”Super Multi-Drill” Extra Long Typ ”Super Multi-Drill” KDS… DAK Type KDS… FA Type Good Chip Removal For Cast Irons and — Aluminium Alloys Delivery on request øD : 9 ~ 22mm øD : 9 ~ 22mm L/D: ~ 7 a K52 ~ 53 L/D: ~ 7 a K54 Recommended Cutting Conditions by Work Materials Drill Work Steel Stainless Steel Cast Iron Non-ferrous Metalls SDP…U HAK 50InnnnnnnI120 0,35 15InnnnnnI70 50InnnnnnI110 0,35MDW…GS0,2I–––––––––I0,1I––––––I0,20,2I–––––––––I— MDS…G — — 25InnnnI80 0,4 80InnnnnnnnnnnI2000,450,25 I––––––––0,25 I–––––––– KDS… AK 50InnnnnnI90 0,35 35InnnnI50 60InnnnI100 0,35(MAK / LAK / DAK)0,15 I––––––––––––I0,15 I––––––I0,250,2I–––––––––I— KDS… FA — — 30InnnnI70 0,5 60InnnnnnI150 0,50,2I–––––––––I0,2I–––––––––I I I nnnnnnnn Cutting speed vc (m/min) I––––––I Feed f (mm/rev) K4

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части