Общий каталог Sumitomo 2018 - 2019 - страница 349

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

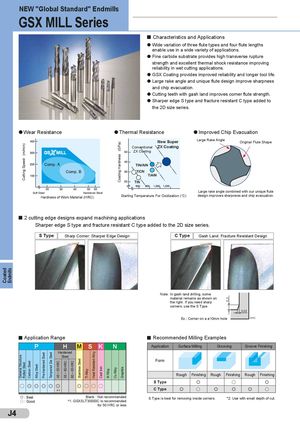

Coated Endmills General Structure (m/min)Cutting SpeedRolled Steel Carbon Steel Alloy Steel Pre-hardened Steel Tempered Die Steel 45 ~ 55 HRC 55 ~ 60 HRC 60 ~ 65 HRC Stainless Steel Ti Alloy Heat Resistant Alloy Cast Iron Al Alloy Cu Alloy (GPa)Coating Hardness Graphite 0,3 NEW "Global Standard" Endmills GSX MILL Series n Characteristics and Applications Wide variation of three flute types and four flute lengths enable use in a wide variety of applications. l Fine carbide substrate provides high transverse rupture strength and excellent thermal shock resistance improving reliability in wet cutting applications. l GSX Coating provides improved reliability and longer tool life. l Large rake angle and unique flute design improve sharpness and chip evacuation. l Cutting teeth with gash land improves corner flute strength. l Sharper edge S type and fracture resistant C type added to the 2D size series. l Wear Resistance l Thermal Resistance l Improved Chip Evacuation New Super Large Rake Angle Original Flute Shape Conventional ZX Coating ZX Coating Comp. A Comp. B Soft Steel Hardened Steel Large rake angle combined with our unique flute Hardness of Work Material (HRC) Starting Temperature For Oxidization (°C) design improves sharpness and chip evacuation. n 2 cutting edge designs expand machining applications Sharper edge S type and fracture resistant C type added to the 2D size series. S Type Sharp Corner: Sharper Edge Design C Type Gash Land: Fracture Resistant Design Note: In gash land drilling, some material remains as shown on the right. If you need sharp corners, use the S Type. 0,02 Ex.: Corner on a ø10mm hole (mm) n Application Range n Recommended Milling Examples P H M S K N Application Surface Milling Grooving Groove Finishing Hardened Steel Form Rough Finishing Rough Finishing Rough Finishing S Type ○ ◎ ◎ ◎ ◎ ◎ ◎ ○ ○ ○*1 C Type ◎ : Best○ : Good Blank : Not recommended S Type is best for removing inside corners. *2: Use with small depth of cut.*1: GSXSLT30000C is recommended for 50 HRC or less J4

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части