Общий каталог Sumitomo 2018 - 2019 - страница 339

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

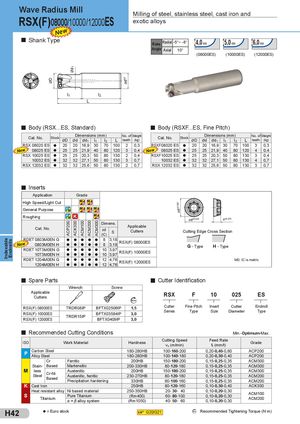

Indexable Endmills ØD ACP200 Ød1 ACK300 ACM100 ACM200 ACM300 Ødh7 Ød±0,025 Wave Radius Mill Milling of steel, stainless steel, cast iron and RSX(F)08000/10000/12000ES exotic alloys New Shank Type Rake Radial -5°~ -8° 4,0 mm 5,0 mm 6,0 mm Angle Axial 10° (08000ES) (10000ES) (12000ES) l1 l2 L Body (RSX...ES, Standard) Body (RSXF...ES, Fine Pitch) Cat. No. Stock ØD Dimensions (mm)ØdØd1 l1 l2 No. of WeightLteeth(kg)Cat. No. Stock ØD Dimensions (mm)ØdØd1l1l2 No. of WeightLteeth(kg) RSX 08020 ES 20 20 16,9 30 70 100 2 0,3 RSXF08020 ES 20 20 16,9 30 70 100 3 0,3 New 08025 ES 25 25 21,9 40 80 120 3 0,4 New 08025 ES 25 25 21,9 40 80 120 4 0,4 RSX 10025 ES 25 25 20,3 50 80 130 2 0,4 RSXF10025 ES 25 25 20,3 50 80 130 3 0,4 10032 ES 32 32 27,1 50 80 130 3 0,7 10032 ES 32 32 27,1 50 80 130 4 0,7 RSX 12032 ES 32 32 25,6 50 80 130 2 0,7 RSX 12032 ES 32 32 25,6 50 80 130 3 0,7 Inserts Application Grade High Speed/Light Cut General Purpose PM Roughing PM K Ød±0,025 s±0,025 Cat. No. Dimens. ApplicableØd(IC)SCutters Cutting Edge Cross Section RDET 0803M0EN GNew0803M0EN Hl l l l llllll 88 3,183,18RSX(F) 08000ESRDET 10T3M0EN G10T3M0EN Hllllllllll10103,973,97RSX(F) 10000ESG - TypeH - Type RDET 1204M0EN G1204M0EN Hll ll ll ll ll 1212 4,764,76RSX(F) 12000ES M0: IC is metric Spare Parts Cutter Identification Wrench Screw ApplicableCutters RSX F 10 025 ES RSX(F) 08000ES TRDR08IP BFTX02506IP 1,5 Cutter Fine Pitch Insert Cutter Endmill RSX(F) 10000ESRSX(F) 12000ESTRDR15IP BFTX03584IPBFTX0409IP 3,03,0 Series Type Size Diameter Type Recommended Cutting Conditions Min.-Optimum-Max. ISO Work Material Hardness Cutting Speedvc (m/min) Feed Rateft (mm/t) Grade P Carbon SteelAlloy Steel 180-280HB 100-160-200 0,20-0,40-0,60 ACP200180-280HB100-140-1800,20-0,30-0,40ACP200 Cr Ferritic 200HB 150-180-200 0,15-0,25-0,35 ACM300 Stain- Based Martensitic 200-330HB 80-120-180 0,15-0,25-0,35 ACM300 M lessSteelCr-NiBased AusteniticAustenitic, ferriticPrecipitation hardening 200HB 150-180-200230-270HB80-120-180330HB60-100-1600,15-0,25-0,35ACM3000,15-0,25-0,35ACM2000,15-0,25-0,35ACM200 K Cast Iron 250HB 80-120-160 0,10-0,30-0,40 ACK300 Heat resistant alloy Ni based materialSTitaniumPure Titaniumα + β alloy system250-350HB 20- 30- 40(Rm400)60- 80-100(Rm1050)40- 50-600,10-0,20-0,300,10-0,20-0,300,10-0,20-0,30ACM100ACM200 H42 l = Euro stock G20/G21 Recommended Tightening Torque (N·m)

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части