Общий каталог Sumitomo 2018 - 2019 - страница 305

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

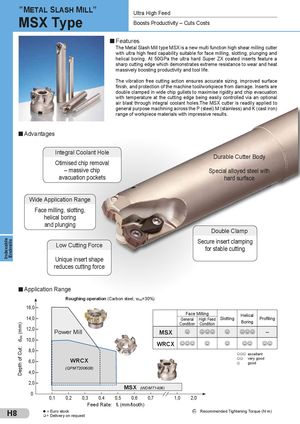

”METAL SLASH MILL” Ultra High Feed MSX Type Boosts Productivity – Cuts Costs Features The Metal Slash Mill type MSX is a new multi function high shear milling cutter with ultra high feed capability suitable for face milling, slotting, plunging and helical boring. At 50GPa the ultra hard Super ZX coated inserts feature a sharp cutting edge which demonstrates extreme resistance to wear and heat massively boosting productivity and tool life. The vibration free cutting action ensures accurate sizing, improved surface finish, and protection of the machine tool/workpiece from damage. Inserts are double clamped in wide chip gullets to maximise rigidity and chip evacuation with temperature at the cutting edge being easily controlled via an optional air blast through integral coolant holes.The MSX cutter is readily applied to general purpose machining across the P (steel) M (stainless) and K (cast iron) range of workpiece materials with impressive results. Advantages Integral Coolant Hole Durable Cutter Body Otimised chip removal – massive chip Special alloyed steel with avacuation pockets hard surface Wide Application Range Face milling, slotting, helical boring and plunging Double Clamp Low Cutting Force Secure insert clampingfor stable cutting Unique insert shape reduces cutting force Application Range Roughing operation (Carbon steel, woc=30%) 16,0 – 14,0 – Face MillingGeneralHigh FeedSlottingConditionConditionHelicalBoringProfiling 12,0 – Power Mill MSX J JJJ J JJJ – 10,0 – WRCX JJJ J J JJ JJ 8,0 – JJJ excellent 6,0 – WRCX JJ very goodJgood (QPMT200608) 4,0 – 2,0 – MSX (WDMT1406) 0 l l l l l l l l l 0,1 0,2 0,3 0,4 0,5 0,6 0,7 1,0 2,0 Feed Rate: ft (mm/tooth) H8 l = Euro stockq = Delivery on request Recommended Tightening Torque (N·m) Indexable Endmills doc (mm)Depth of Cut:

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части