Общий каталог Sumitomo 2018 - 2019 - страница 279

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

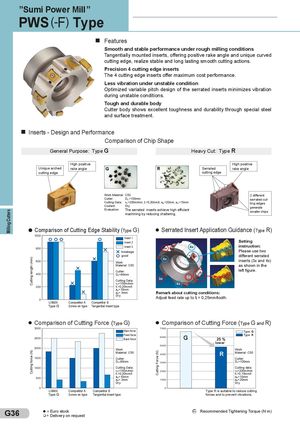

Milling Cutters Cutting length (mm)Cutting force (N) Cutting Force (N) ”Sumi Power Mill” PWS(-F) Type Features Smooth and stable performance under rough milling conditions Tangentially mounted inserts, offering positive rake angle and unique curved cutting edge, realize stable and long lasting smooth cutting actions. Precision 4 cutting edge inserts The 4 cutting edge inserts offer maximum cost performance. Less vibration under unstable condition Optimized variable pitch design of the serrated inserts minimizes vibration during unstable conditions. Tough and durable body Cutter body shows excellent toughness and durability through special steel and surface treatment. Inserts - Design and Performance Comparison of Chip Shape General Purpose: Type G Heavy Cut: Type R High positive High positive Unique arched rake angle G R Serrated rake angle cutting edge cutting edge Work Material: C50 2 different Cutter: Dc =100mm serrated cut- Cutting Data: vc =200m/min, ft =0,20mm/t, ap =20mm, ae =10mm ting edges Coolant: DryEvaluation:The serratedinserts achieve high efficientmachining by reducing chattering. generatesmaller chips Comparison of Cutting Edge Stability (Type G) Serrated Insert Application Guidance (Type R) 1000 Insert 1 Insert 2 Setting 800 Insert 3 3x 4xbreakage instruction:Please use two good different serrated 600 4xWork inserts (3x and 4x) Material: C50 as shown in the Cutter: left figure. 400 Dc=80mmCutting Data: 3x 3x vc=150m/min 4x 200 ft =0,20mm/t ap=10mm ae= 3mm Remark about cutting conditions: 0 Dry Adjust feed rate up to ft = 0,25mm/tooth. LNMX Competitor A Competitor B Type:G Screw on type Tangential insert type Comparison of Cutting Force (Type G) Comparison of Cutting Force (Type G and R) 3000 7000 Main force Type: G 2500 Feed forceBack force 6000 G Type: R25 % lower 5000 2000 Work Work Material: C50 4000 R Material: C50 1500 Cutter: Cutter: Dc=80mm 3000 Dc=100mm 1000 Cutting Data: Cutting data: vc=150m/min 2000 vc=200m/min ft =0,20mm/t ft =0,15mm/t 500 ap=10mm ap=10mmae= 3mm1000ae=20mm Dry Dry 0 0 LNMX Competitor A Competitor B Type R is suitable to reduce cutting Type:G Screw on type Tangential insert type forces and to prevent vibrations. G36 l = Euro stockq = Delivery on request Recommended Tightening Torque (N·m)

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части