Общий каталог Sumitomo 2018 - 2019 - страница 272

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

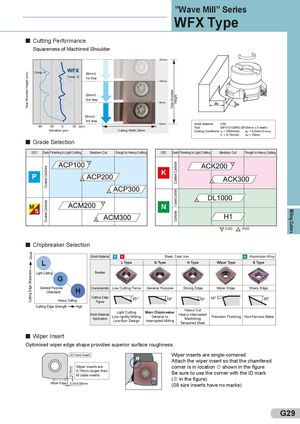

Total Shoulder Height (mm) GoodCutting Edge Sharpness Coated CarbideCoated Carbide 0,15mm Total Shoulder HeightCoated CarbideCoated CarbideCarbide Milling Cutters ”Wave Mill” Series WFX Type Cutting Performance Squareness of Machined Shoulder Comp. A Comp. B 1st Step 2nd Step 3rd Step Work Material: C50 -60 -30 0 30 (µm) Tool: WFX12100RS (Ø100mm x 5 teeth) Deviation (µm) Cutting Width 20mm Cutting Conditions: vc = 200m/min, ap = 8,0mmx3 times ft = 0,15mm/t, ae = 20mm Grade Selection ISO Grade Finishing to Light Cutting Medium Cut Rough to Heavy Cutting ISO Grade Finishing to Light Cutting Medium Cut Rough to Heavy Cutting P K MS N CVD PVD Chipbreaker Selection Work Material P K Steel, Cast Iron N Aluminium Alloy L L Type G Type H Type Wiper Type S Type Light Cutting Breaker G General Purpose(Standard) H Characteristic Low Cutting Force General Purpose Strong Edge Wiper Edge Sharp Edge Cutting Edge Heavy Cutting Figure Cutting Edge Strength High Work Material-ApplicationLight CuttingLow rigidity MillingLow-Burr DesignMain ChipbreakerGeneral toInterrupted MillingHeavy CutHeavy InterruptedMachiningTempered SteelPrecision FinishingNon-Ferrous Metal Wiper Insert Optimised wiper edge shape provides superior surface roughness. M Class Insert Wiper inserts are single-cornered. Attach the wiper insert so that the chamfered Wiper inserts are corner is in location shown in the figure. 0,15mm longer thanM class inserts. Be sure to use the corner with the ID mark ( in the figure). Wiper Edge 0,03-0,05mm (08 size inserts have no marks) G29

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части