Общий каталог Sumitomo 2018 - 2019 - страница 270

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

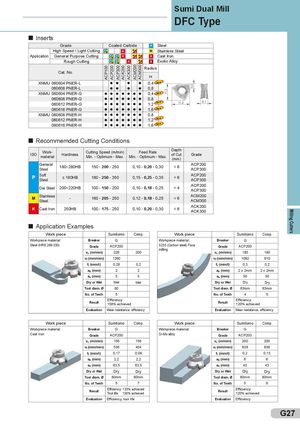

ACP100 ACP200 ACP300 ACK200 ACK300 ACM200 ACM300 11,3 3,2 Milling Cutters Sumi Dual Mill DFC Type Inserts Grade Coated Carbide P Steel High Speed / Light Cutting PM K MS M Stainless Steel Application General Purpose Cutting PM PM K MS MS K Cast Iron Rough Cutting PM PM K MS S Exotic Alloy Radius Cat. No. rε XNMU 060604 PNER-L 0,4 New 060608 PNER-L 0,8 XNMU 060604 PNER-G 0,4 New 060608 PNER-G 0,8 060612 PNER-G 1,2 New 11,2 6,1 060616 PNER-G 1,6 New XNMU 060608 PNER-H 0,8 060612 PNER-H 1,2 New 060616 PNER-H 1,6 New Recommemded Cutting Conditions ISO Work-material Hardness Cutting Speed (m/min)Min. - Optimum - Max. Feed RateMin. - Optimum - Max.Depthof Cut(mm)Grade GeneralSteel180~280HB 150 - 200 - 250 0,10 - 0,20 - 0,30 <6 ACP200ACP300 P SoftSteel ≤ 180HB 180 - 250 - 350 0,15 - 0,25 - 0,35 <6 ACP200ACP300 Die Steel 200~220HB 100 - 150 - 200 0,10 - 0,18 - 0,25 <4 ACP200ACP300 M StainlessSteel - 160 - 205 - 250 0,12 - 0,18 - 0,25 <6 ACM200ACM300 K Cast Iron 250HB 100 - 175 - 250 0,10 - 0,20 - 0,30 <6 ACK200ACK300 Application Examples Work piece Sumitomo Comp. Work piece Sumitomo Comp. Workpiece material: Breaker G Workpiece material: Breaker G Steel (HRB 269-330) Grade ACP200 S235 (Carbon steel) Face Grade ACP200 milling vc (m/min) 226 200 vc (m/min) 180 180 vf (mm/min) 1260 vf (mm/min) 1092 910 ft (mm/t) 0,28 0,2 ft (mm/t) 0,3 0,2 ap (mm) 2 2 ap (mm) 2 x 2mm 2 x 2mm ae (mm) 5 5 ae (mm) 50 50 Dry or Wet Wet Wet Dry or Wet Dry Dry Tool diam. Ø 80 Tool diam. Ø 63mm 63mm No. of Teeth 5 No. of Teeth 4 5 Result Efficiency:158% achieved Result Efficiency:120% achieved Evaluation Wear resistance, efficiency Evaluation Wear resistance, efficiency Work piece Sumitomo Comp. Work piece Sumitomo Comp. Workpiece material: Breaker G Workpiece material: Breaker G Cast Iron Grade ACP200 Cr-Mo alloy Grade ACP200 vc (m/min) 156 156 vc (m/min) 200 200 vf (mm/min) 536 404 vf (mm/min) 838 838 ft (mm/t) 0,17 0,09 ft (mm/t) 0,2 0,13 ap (mm) 2,2 2,2 ap (mm) 6 6 ae (mm) 63,5 63,5 ae (mm) 43 43 Dry or Wet Dry Dry Dry or Wet Dry Dry Tool diam. Ø 80mm 80mm Tool diam. Ø 80mm 80mm No. of Teeth 5 7 No. of Teeth 5 8 Result Efficiency: 133% achievedTool life:138% achieved Result Efficiency:120% achieved Evaluation Efficiency, tool life Evaluation Efficiency G27

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части