Общий каталог Sumitomo 2018 - 2019 - страница 250

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

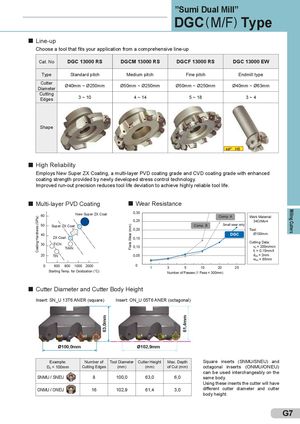

Coating Hardness (GPa) 63,0mm Flank Wear (mm) 61,4mm Milling Cutters ”Sumi Dual Mill” DGC(M/F) Type Line-up Choose a tool that fits your application from a comprehensive line-up Cat. No DGC 13000 RS DGCM 13000 RS DGCF 13000 RS DGC 13000 EW Type Standard pitch Medium pitch Fine pitch Endmill type CutterDiameterØ40mm ~ Ø250mm Ø50mm ~ Ø250mm Ø50mm ~ Ø250mm Ø40mm ~ Ø63mm Cutting Edges 3 ~ 10 4 ~ 14 5 ~ 18 3~4 Shape H6 High Reliability Employs New Super ZX Coating, a multi-layer PVD coating grade and CVD coating grade with enhanced coating strength provided by newly developed stress control technology. Improved run-out precision reduces tool life deviation to achieve highly reliable tool life. Multi-layer PVD Coating Wear Resistance 60 New Super ZX Coat 0,30 Comp. A Work Material: 0,25 34CrMo4 50 Super ZX Coat Comp. B Small wear only 0,20 Tool: 40 DGC Ø100mm ZX Coat 0,15 30 TiCN TiAlN 0,10 Cutting Data:vc = 200m/minft = 0,15mm/t 20 TiN 0,05 doc = 2mm woc = 85mm 0 600 800 1000 2000 0 1 3 5 10 20 25 Starting Temp. for Oxidization (°C) Number of Passes (1 Pass = 300mm) Cutter Diameter and Cutter Body Height Insert: SN_U 13T6 ANER (square) Insert: ON_U 05T6 ANER (octagonal) Ø100,0mm Ø102,9mm Example: Number of Tool Diameter Cutter Height Max. Depth Square inserts (SNMU/SNEU) and Dc = 100mm Cutting Edges (mm) (mm) of Cut (mm) octagonal inserts (ONMU/ONEU) can be used interchangeably on the SNMU / SNEU 8 100,0 63,0 6,0 same body. Using these inserts the cutter will have ONMU / ONEU 16 102,9 61,4 3,0 different cutter diameter and cutter body height. G7

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части