Общий каталог Sumitomo 2018 - 2019 - страница 226

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

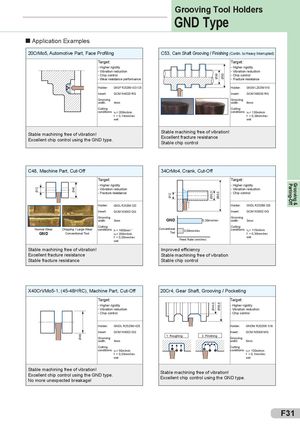

Ø12 Ø40 Ø48 Ø12 Ø30,3Ø44,0 Ø36Ø85,0Ø56,8 Ø50 Parting-Off Grooving & Grooving Tool Holders GND Type Application Examples 20CrMo5, Automotive Part, Face Profiling C53, Cam Shaft Grooving / Finishing (Contin. to Heavy Interrupted) Target: Target: - Higher rigidity - Higher rigidity - Vibration reduction - Vibration reduction - Chip control - Chip control - Wear resistance performance - Fracture resistance Holder: GNDF R2525M 423-125 Holder: GNDM L2525M 618 Insert: GCM N4020 RG Insert: GCM N6030 RG Grooving Grooving width: 4mm width: 6mm Cutting Cutting conditions: vc= 200m/min conditions: vc= 130m/min f = 0,14mm/rev f = 0,36mm/rev wet wet Stable machining free of vibration!Excellent chip control using the GND type. Stable machining free of vibration!Excellent fracture resistanceStable chip control C48, Machine Part, Cut-Off 34CrMo4, Crank, Cut-Off Target: Target: - Higher rigidity - Higher rigidity - Vibration reduction - Vibration reduction - Fracture resistance - Chip control Holder: GNDL R2525M 320 Holder: GNDL R2525M 320 Insert: GCM N3002 GG Insert: GCM N3002 GG Groovingwidth:3mm GND Grooving0,30mm/revwidth:3mm Cutting Cutting Normal Wear Chipping / Large Wear conditions: n = 1600min-1GNDConventional Toolvc= 200m/minConventionalTool 0,08mm/rev conditions: vc= 115m/minf= 0,30mm/rev f = 0,05mm/revwet wetFeed Rate (mm/rev) Stable machining free of vibration! Improved efficiency Excellent fracture resistance Stable machining free of vibration Stable fracture resistance Stable chip control X40CrVMo5-1, (45-48HRC), Machine Part, Cut-Off 20Cr4, Gear Shaft, Grooving / Pocketing Target: Target: - Higher rigidity - Higher rigidity - Vibration reduction - Vibration reduction - Chip control - Chip control Holder: GNDL R2525M 425 Holder: GNDM R2020K 518 Insert: GCM N4002 GG Insert: GCM N5008 MG Grooving 1. Roughing 2. Finishing Grooving width: 4mm width: 5mm Cuttingconditions: vc= 50m/min 1 2 3 Cutting213conditions: vc= 150m/min f = 0,03mm/rev f = 0,1mm/rev wet wet Stable machining free of vibration!Excellent chip control using the GND type.No more unexpected breakage!Stable machining free of vibration!Excellent chip control using the GND type. F31

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части