Общий каталог Sumitomo 2018 - 2019 - страница 199

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

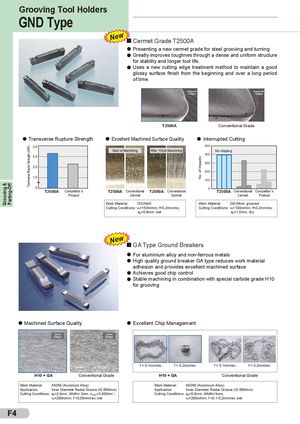

Grooving & Parting-Off Transverse Ruptur Strength (GPA) No. of Impacts Grooving Tool Holders GND Type New Cermet Grade T2500A Presenting a new cermet grade for steel grooving and turning Greatly improves toughnes through a dense and uniform structure for stability and longer tool life. Uses a new cutting edge treatment method to maintain a good glossy surface finish from the beginning and over a long period of time. 100μm 100μm T2500A Conventional Grade Transverse Rupture Strength Excellent Machined Surface Qualitiy Interrupted Cutting 3,0 500 Start of Machining After 10min Machining No chipping 2,5 400 300 2,0 200 1,5 100 0 0 T2500A Competitor`s T2500A Conventional T2500A Conventional T2500A Conventional Competitor`s Product Cermet Cermet Cermet Product Work Material: 15CrMo5 Work Material: 34CrMo4, grooved Cutting Conditions: vc=150m/min, f=0,2mm/rev, Cutting Conditions: vc=100m/min, f=0,2mm/rev, ap=0,8mm, wet ap=1,0mm, dry New GA Type Ground Breakers For aluminium alloy and non-ferrous metals High quality ground breaker GA type reduces work material adhesion and provides excellent machined surface Achieves good chip control Stable machining in combination with special carbide grade H10 for grooving Machined Surface Quality Excellent Chip Management 200μm 200μm f = 0,1mm/rev f = 0,2mm/rev f = 0,1mm/rev f = 0,2mm/rev H10 + GA Conventional Grade H10 + GA Conventional Grade Work Material: A5056 (Aluminium Alloy) Work Material: A5056 (Aluminium Alloy) Application: Inner Diameter Radial Groove (ID Ø60mm) Application: Inner Diameter Radial Groove (ID Ø60mm) Cutting Conditions: ap=2,8mm, Width= 3mm, nmax=3.500min-1, Cutting Conditions: ap=5,0mm, Width=3mm, vc=200m/min, f =0,05mm/rev, wet vc=200m/min, f =0,1-0,2mm/rev, wet F4

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части