Общий каталог Sumitomo 2018 - 2019 - страница 114

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

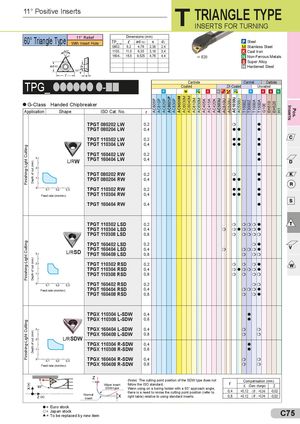

Finishing-Light CuttingFinishing-Light CuttingFinishing-Light Cutting Depth of cut (mm)Depth of cut (mm)Depth of cut (mm) AC805P AC810P AC820P AC8025P AC830P AC6020M AC6030M AC6040M AC610M AC630M AC405K AC415K AC420K AC503U AC510U AC520U AC1030U AC530U T1500Z T3000Z T1000A T1500A G10E EH510 EH520 H1 Inserts Pos. 11° Positive Inserts T TRIANGLE TYPE INSERTS FOR TURNING 60° Triangle Type 11° ReliefWith Insert Hole Dimensions (mm)TP_ _lød (IC)sd1 P Steel 0802.. 8,2 4,76 2,38 2,4 M Stainless Steel 1103.. 11,0 6,35 3,18 3,4 K Cast Iron 1604.. 16,5 9,525 4,76 4,4 a E20 N Non-Ferrous Metals S Super Alloy H Hardened Steel TPG_ llllll l-nn Carbide Cermet CarbideCoatedZX-CoatedUncoatedPMPMKHKSMSPMPKSN G-Class Handed Chipbreaker Application Shape ISO Cat. No. r TPGT 080202 LW 0,2 m l TPGT 080204 LW 0,4 ll l TPGT 110302 LW 0,2 ll l TPGT 110304 LW 0,4 ll l TPGT 160402 LW 0,2 l L/RW TPGT 160404 LW 0,4 l TPGT 080202 RW 0,2 m l TPGT 080204 RW 0,4 ll l TPGT 110302 RW 0,2 ll l Feed rate (mm/rev) TPGT 110304 RW 0,4 ll l TPGT 160404 RW 0,4 l TPGT 110302 LSD 0,2 m mmml TPGT 110304 LSD 0,4 m mlmmml TPGT 110308 LSD 0,8 m mmmm TPGT 160402 LSD 0,2 ml L/RSD TPGT 160404 LSDTPGT 160408 LSD 0,40,8 m mmmlm mm TPGT 110302 RSD 0,2 m m ml TPGT 110304 RSD 0,4 mlmmml TPGT 110308 RSD 0,8 m m mm TPGT 160402 RSD 0,2 mm Feed rate (mm/rev) TPGT 160404 RSD 0,4 mmml TPGT 160408 RSD 0,8 m ml TPGX 110304 L-SDW 0,4 l TPGX 110308 L-SDW 0,8 l TPGX 160404 L-SDW 0,4 m m TPGX 160408 L-SDW 0,8 m m L/RSDW TPGX 110304 R-SDW 0,4 l TPGX 110308 R-SDW 0,8 l TPGX 160404 R-SDW 0,4 m m Feed rate (mm/rev) TPGX 160408 R-SDW 0,8 m m (Note) The cutting point position of the SDW type does notWiper insertfollow the ISO standard.SDW typeWenn using on a boring holder with a 93° approach angle,Normalinsertthere is a need to revise the cutting point position (refer toright table) relative to using standard inserts.rCompensation (mm)X(Diam. change)Z0,4+0,12( Ø : +0,24)-0,020,8+0,12( Ø : +0,24)-0,02 l= Euro stock = Japan stocks = To be replaced by new item C75

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части