Каталог Stellram высокопроизводительные фрезерные системы - страница 7

Навигация

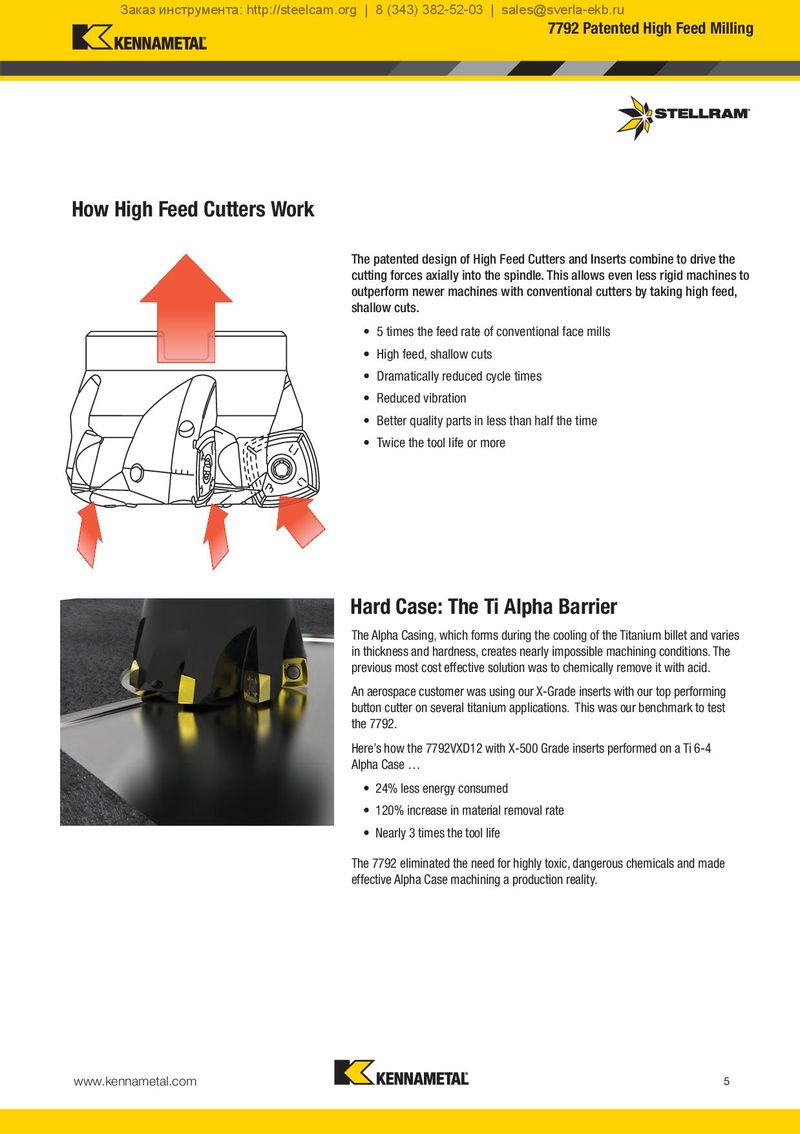

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 7792 Patented High Feed Milling How High Feed Cutters Work The patented design of High Feed Cutters and Inserts combine to drive the cutting forces axially into the spindle. This allows even less rigid machines to outperform newer machines with conventional cutters by taking high feed, shallow cuts. • 5 times the feed rate of conventional face mills • High feed, shallow cuts • Dramatically reduced cycle times • Reduced vibration • Better quality parts in less than half the time • Twice the tool life or more Hard Case: The Ti Alpha Barrier The Alpha Casing, which forms during the cooling of the Titanium billet and varies in thickness and hardness, creates nearly impossible machining conditions. The previous most cost effective solution was to chemically remove it with acid. An aerospace customer was using our X-Grade inserts with our top performing button cutter on several titanium applications. This was our benchmark to test the 7792. Here’s how the 7792VXD12 with X-500 Grade inserts performed on a Ti 6-4 Alpha Case … • 24% less energy consumed • 120% increase in material removal rate • Nearly 3 times the tool life The 7792 eliminated the need for highly toxic, dangerous chemicals and made effective Alpha Case machining a production reality. www.kennametal.com 5

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами