Каталог Stellram токарный инструмент - страница 34

Навигация

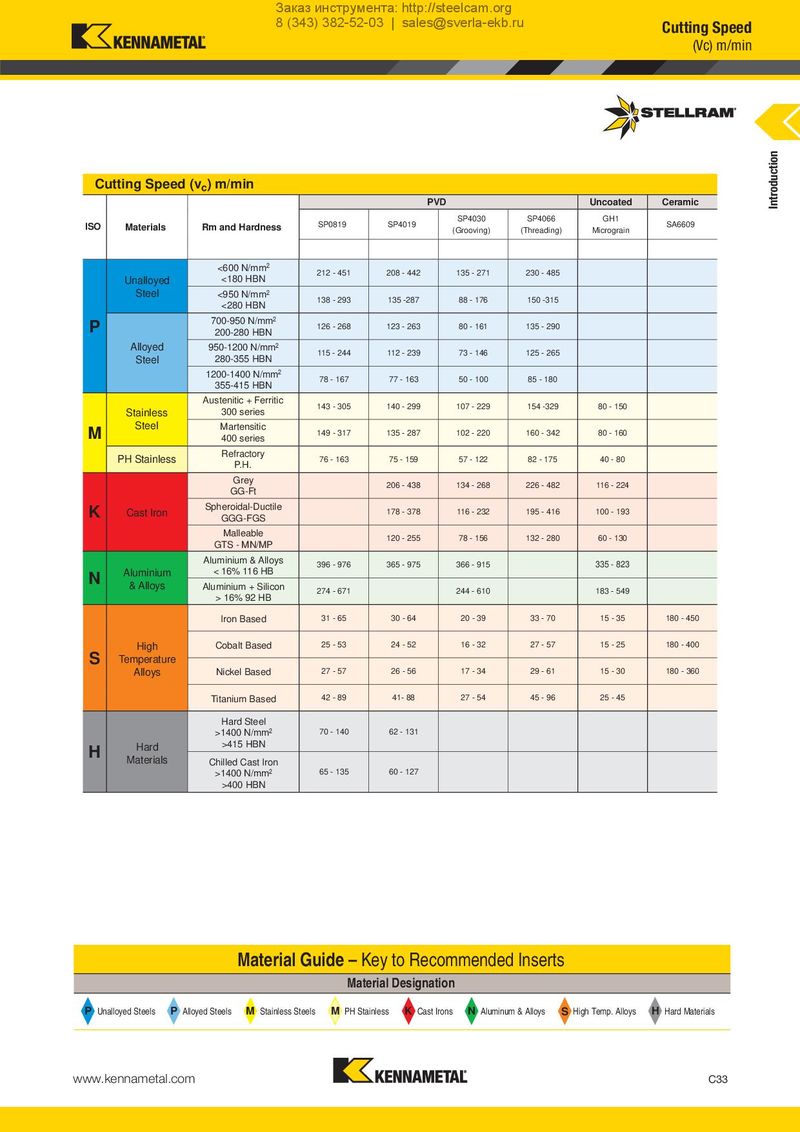

Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru Cutting Speed (Vc) m/min Cutting Speed (vc) m/min Introduction PVD Uncoated Ceramic SP0819 SP4019 SP4030 SP4066 GH1 SA6609 ISO Materials Rm and Hardness (Grooving) (Threading) Micrograin <600 N/mm2 212 - 451 208 - 442 135 - 271 230 - 485 Unalloyed <180 HBN Steel <950 N/mm2 138 - 293 135 -287 88 - 176 150 -315 <280 HBN P 700-950 N/mm2 126 - 268 123 - 263 80 - 161 135 - 290 200-280 HBN Alloyed 950-1200 N/mm2 115 - 244 112 - 239 73 - 146 125 - 265 Steel 280-355 HBN 1200-1400 N/mm2 78 - 167 77 - 163 50 - 100 85 - 180 355-415 HBN Austenitic + Ferritic 143 - 305 140 - 299 107 - 229 154 -329 80 - 150 Stainless 300 series M Steel Martensitic 149 - 317 135 - 287 102 - 220 160 - 342 80 - 160 400 series PH Stainless Refractory 76 - 163 75 - 159 57 - 122 82 - 175 40 - 80 P.H. Grey 206 - 438 134 - 268 226 - 482 116 - 224 GG-Ft K Cast Iron Spheroidal-Ductile 178 - 378 116 - 232 195 - 416 100 - 193 GGG-FGS Malleable 120 - 255 78 - 156 132 - 280 60 - 130 GTS - MN/MP Aluminium & Alloys 396 - 976 365 - 975 366 - 915 335 - 823 N Aluminium < 16% 116 HB & Alloys Aluminium + Silicon 274 - 671 244 - 610 183 - 549 > 16% 92 HB Iron Based 31 - 65 30 - 64 20 - 39 33 - 70 15 - 35 180 - 450 High Cobalt Based 25 - 53 24 - 52 16 - 32 27 - 57 15 - 25 180 - 400 S Temperature Alloys Nickel Based 27 - 57 26 - 56 17 - 34 29 - 61 15 - 30 180 - 360 Titanium Based 42 - 89 41- 88 27 - 54 45 - 96 25 - 45 Hard Steel >1400 N/mm2 70 - 140 62 - 131 H Hard >415 HBN Materials Chilled Cast Iron >1400 N/mm2 65 - 135 60 - 127 >400 HBN Material Guide – Key to Recommended Inserts Material Designation P Unalloyed Steels P Alloyed Steels M Stainless Steels M PH Stainless K Cast Irons N Aluminum & Alloys S High Temp. Alloys H Hard Materials www.kennametal.com C33

Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами