Каталог Stellram материалы и сплавы - страница 34

Навигация

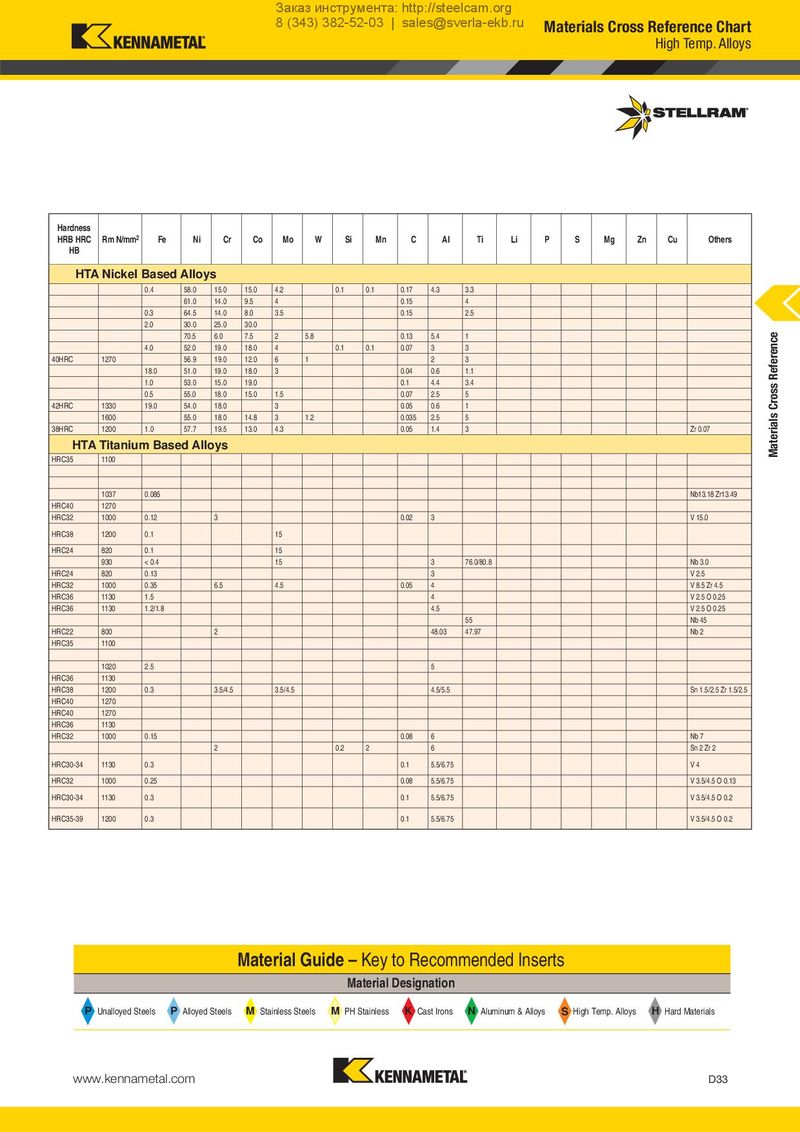

Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru Materials Cross Reference Chart High Temp. Alloys Hardness HRB HRC Rm N/mm2 Fe Ni Cr Co Mo W Si Mn C Al Ti Li P S Mg Zn Cu Others HB HTA Nickel Based Alloys 0.4 58.0 15.0 15.0 4.2 0.1 0.1 0.17 4.3 3.3 61.0 14.0 9.5 4 0.15 4 0.3 64.5 14.0 8.0 3.5 0.15 2.5 2.0 30.0 25.0 30.0 70.5 6.0 7.5 2 5.8 0.13 5.4 1 Materials Cross Reference 4.0 52.0 19.0 18.0 4 0.1 0.1 0.07 3 3 40HRC 1270 56.9 19.0 12.0 6 1 2 3 18.0 51.0 19.0 18.0 3 0.04 0.6 1.1 1.0 53.0 15.0 19.0 0.1 4.4 3.4 0.5 55.0 18.0 15.0 1.5 0.07 2.5 5 42HRC 1330 19.0 54.0 18.0 3 0.05 0.6 1 1600 55.0 18.0 14.8 3 1.2 0.035 2.5 5 38HRC 1200 1.0 57.7 19.5 13.0 4.3 0.05 1.4 3 Zr 0.07 HTA Titanium Based Alloys HRC35 1100 1037 0.085 Nb13.18 Zr13.49 HRC40 1270 HRC32 1000 0.12 3 0.02 3 V 15.0 HRC38 1200 0.1 15 HRC24 820 0.1 15 930 < 0.4 15 3 76.0/80.8 Nb 3.0 HRC24 820 0.13 3 V 2.5 HRC32 1000 0.35 6.5 4.5 0.05 4 V 8.5 Zr 4.5 HRC36 1130 1.5 4 V 2.5 O 0.25 HRC36 1130 1.2/1.8 4.5 V 2.5 O 0.25 55 Nb 45 HRC22 800 2 48.03 47.97 Nb 2 HRC35 1100 1020 2.5 5 HRC36 1130 HRC38 1200 0.3 3.5/4.5 3.5/4.5 4.5/5.5 Sn 1.5/2.5 Zr 1.5/2.5 HRC40 1270 HRC40 1270 HRC36 1130 HRC32 1000 0.15 0.08 6 Nb 7 2 0.2 2 6 Sn 2 Zr 2 HRC30-34 1130 0.3 0.1 5.5/6.75 V4 HRC32 1000 0.25 0.08 5.5/6.75 V 3.5/4.5 O 0.13 HRC30-34 1130 0.3 0.1 5.5/6.75 V 3.5/4.5 O 0.2 HRC35-39 1200 0.3 0.1 5.5/6.75 V 3.5/4.5 O 0.2 Material Guide – Key to Recommended Inserts Material Designation P Unalloyed Steels P Alloyed Steels M Stainless Steels M PH Stainless K Cast Irons N Aluminum & Alloys S High Temp. Alloys H Hard Materials www.kennametal.com D33

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами