Каталог Stellram материалы и сплавы - страница 30

Навигация

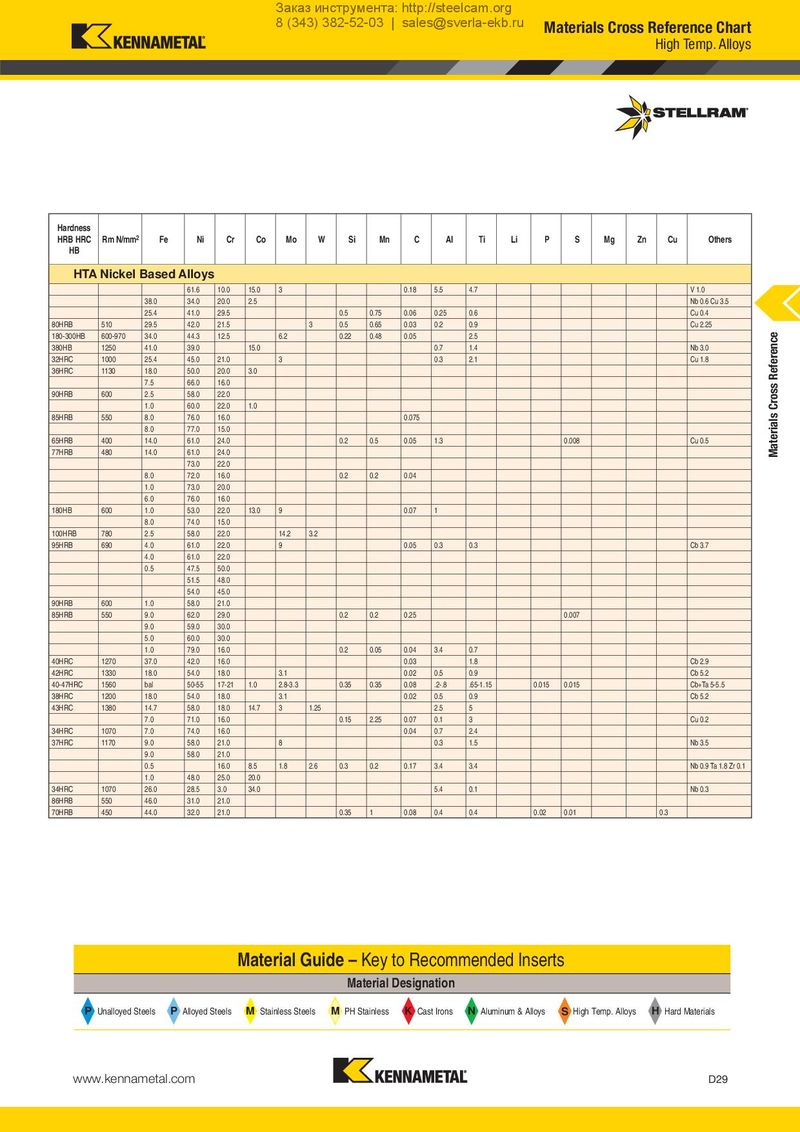

Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru Materials Cross Reference Chart High Temp. Alloys Hardness HRB HRC Rm N/mm2 Fe Ni Cr Co Mo W Si Mn C Al Ti Li P S Mg Zn Cu Others HB HTA Nickel Based Alloys 61.6 10.0 15.0 3 0.18 5.5 4.7 V 1.0 38.0 34.0 20.0 2.5 Nb 0.6 Cu 3.5 25.4 41.0 29.5 0.5 0.75 0.06 0.25 0.6 Cu 0.4 80HRB 510 29.5 42.0 21.5 3 0.5 0.65 0.03 0.2 0.9 Cu 2.25 180-300HB 600-970 34.0 44.3 12.5 6.2 0.22 0.48 0.05 2.5 Materials Cross Reference 380HB 1250 41.0 39.0 15.0 0.7 1.4 Nb 3.0 32HRC 1000 25.4 45.0 21.0 3 0.3 2.1 Cu 1.8 36HRC 1130 18.0 50.0 20.0 3.0 7.5 66.0 16.0 90HRB 600 2.5 58.0 22.0 1.0 60.0 22.0 1.0 85HRB 550 8.0 76.0 16.0 0.075 8.0 77.0 15.0 65HRB 400 14.0 61.0 24.0 0.2 0.5 0.05 1.3 0.008 Cu 0.5 77HRB 480 14.0 61.0 24.0 73.0 22.0 8.0 72.0 16.0 0.2 0.2 0.04 1.0 73.0 20.0 6.0 76.0 16.0 180HB 600 1.0 53.0 22.0 13.0 9 0.07 1 8.0 74.0 15.0 100HRB 780 2.5 58.0 22.0 14.2 3.2 95HRB 690 4.0 61.0 22.0 9 0.05 0.3 0.3 Cb 3.7 4.0 61.0 22.0 0.5 47.5 50.0 51.5 48.0 54.0 45.0 90HRB 600 1.0 58.0 21.0 85HRB 550 9.0 62.0 29.0 0.2 0.2 0.25 0.007 9.0 59.0 30.0 5.0 60.0 30.0 1.0 79.0 16.0 0.2 0.05 0.04 3.4 0.7 40HRC 1270 37.0 42.0 16.0 0.03 1.8 Cb 2.9 42HRC 1330 18.0 54.0 18.0 3.1 0.02 0.5 0.9 Cb 5.2 40-47HRC 1560 bal 50-55 17-21 1.0 2.8-3.3 0.35 0.35 0.08 .2-.8 .65-1.15 0.015 0.015 Cb+Ta 5-5.5 38HRC 1200 18.0 54.0 18.0 3.1 0.02 0.5 0.9 Cb 5.2 43HRC 1380 14.7 58.0 18.0 14.7 3 1.25 2.5 5 7.0 71.0 16.0 0.15 2.25 0.07 0.1 3 Cu 0.2 34HRC 1070 7.0 74.0 16.0 0.04 0.7 2.4 37HRC 1170 9.0 58.0 21.0 8 0.3 1.5 Nb 3.5 9.0 58.0 21.0 0.5 16.0 8.5 1.8 2.6 0.3 0.2 0.17 3.4 3.4 Nb 0.9 Ta 1.8 Zr 0.1 1.0 48.0 25.0 20.0 34HRC 1070 26.0 28.5 3.0 34.0 5.4 0.1 Nb 0.3 86HRB 550 46.0 31.0 21.0 70HRB 450 44.0 32.0 21.0 0.35 1 0.08 0.4 0.4 0.02 0.01 0.3 Material Guide – Key to Recommended Inserts Material Designation P Unalloyed Steels P Alloyed Steels M Stainless Steels M PH Stainless K Cast Irons N Aluminum & Alloys S High Temp. Alloys H Hard Materials www.kennametal.com D29

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами