Общий каталог SGS 2021 - страница 96

Навигация

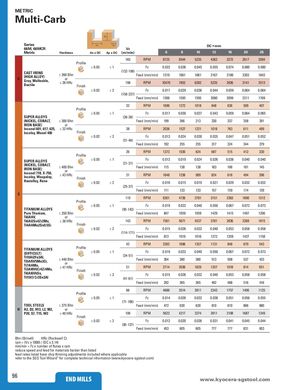

METRIC Multi-Carb Ap Series Ae Ae DC • mm 66M, 66MCR Vc Metric Hardness Ae x DC Ap x DC (m/min) 6 8 10 12 16 20 25 165 RPM 8725 6544 5235 4362 3272 2617 2094 Profile ≤ 0.05 ≤1 Fz 0.022 0.036 0.045 0.055 0.074 0.080 0.080 CAST IRONSK(HIGH ALLOY)Gray, Malleable,Ductile≤ 260 Bhnor≤ 26 HRcFinish (132-198) Feed (mm/min) 1319 1661 1661 2167 2186 2303 1843198RPM10470785262825235392631412513 ≤ 0.02 ≤2 Fz 0.017 0.029 0.036 0.044 0.059 0.064 0.064 (158-237) Feed (mm/min) 1266 1595 1595 2080 2099 2211 1769 32 RPM 1696 1272 1018 848 636 509 407 Profile ≤ 0.05 ≤1 Fz 0.017 0.030 0.037 0.043 0.059 0.064 0.065 SUPER ALLOYS (26-38) (NICKEL, COBALT, ≤ 300 Bhn Feed (mm/min) 199 266 213 330 337 358 291 IRON BASE) or Inconel 601, 617, 625, ≤ 32 HRc 38 RPM 2036 1527 1221 1018 763 611 489 Incoloy, Monel 400 Finish ≤ 0.02 ≤2 Fz 0.013 0.024 0.030 0.035 0.047 0.051 0.052 (31-46) Feed (mm/min) 192 255 255 317 324 344 279 26 RPM 1373 1030 824 687 515 412 330 Profile SUPER ALLOYS ≤ 0.05(NICKEL, COBALT,IRON BASE)Inconel 718, X-750,Incoloy, Waspaloy,≤ 400 Bhnor≤ 43 HRcFinish≤1Fz0.0120.0190.0240.0260.0360.0400.040(21-31)Feed (mm/min)11513813816316618114531RPM16481236989824618494396 Hastelloy, Rene ≤ 0.02 ≤2 Fz 0.010 0.015 0.019 0.021 0.029 0.032 0.032 (25-37) Feed (mm/min) 111 133 133 157 159 174 139 S 119 RPM 6301 4726 3781 3151 2363 1890 1512 Profile ≤ 0.05 ≤1 Fz 0.019 0.032 0.040 0.050 0.067 0.072 0.073 TITANIUM ALLOYS (95-143) Pure Titanium, ≤ 350 Bhn Feed (mm/min) 847 1059 1059 1429 1415 1497 1206 Ti6Al4V, or Ti6Al2Sn4Zr2Mo, ≤ 38 HRc 143 RPM 7561 5671 4537 3781 2836 2268 1815 Ti4Al4Mo2Sn0.5Si Finish ≤ 0.02 ≤2 Fz 0.015 0.026 0.032 0.040 0.053 0.058 0.058 (114-171) Feed (mm/min) 813 1016 1016 1372 1359 1437 1158 43 RPM 2262 1696 1357 1131 848 679 543 TITANIUM ALLOYS(DIFFICULT) Profile ≤ 0.05Ti10Al2Fe3Al,Ti5Al5V5Mo3Cr,Ti7Al4Mo,Ti3Al8V6Cr4Zr4Mo,≤ 440 Bhnor≤ 47 HRcFinish≤1Fz0.0190.0320.0400.0500.0670.0720.073(34-51)Feed (mm/min)30438038051350853743351RPM27142036162913571018814651 Ti6Al6V6Sn,Ti15V3 Cr3Sn3Al ≤ 0.02 ≤2 Fz 0.015 0.026 0.032 0.040 0.053 0.058 0.058(41-61) Feed (mm/min) 292 365 365 492 488 516 416 88 RPM 4686 3514 2811 2343 1757 1406 1125 Profile ≤ 0.05 ≤1 Fz 0.014 0.026 0.032 0.038 0.051 0.056 0.055 (71-106) TOOL STEELS ≤ 375 Bhn Feed (mm/min) 472 630 630 810 810 866 680 H A2, D2, H13, L2, M2, or P20, S7, T15, W2 ≤ 40 HRc 106 RPM 5623 4217 3374 2811 2108 1687 1349 Finish ≤ 0.02 ≤2 Fz 0.012 0.020 0.026 0.031 0.041 0.045 0.044 (85-127) Feed (mm/min) 453 605 605 777 777 831 653 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 1000) / (DC x 3.14) mm/min = Fz x number of flutes x rpm reduce speed and feed for materials harder than listed feed rates listed have chip thinning adjustments included where applicable refer to the SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) 96 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов