Общий каталог SGS 2021 - страница 87

Навигация

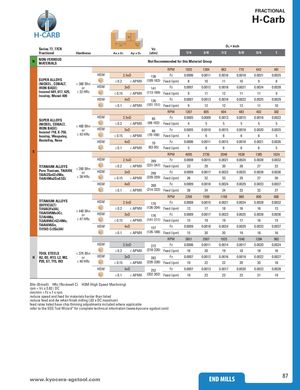

FRACTIONAL 77 H-Carb H-CARB Ap Ae AeSeries 77, 77CRVc D1 • inch Fractional Hardness Ae x D1 Ap x D1 (sfm) 1/4 3/8 1/2 5/8 3/4 1 N NON-FERROUSMATERIALS Not Recommended for this Material Group RPM 1925 1284 963 770 642 481 HSM 2.5xD 136 Fz 0.0006 0.0011 0.0016 0.0018 0.0021 0.0025 SUPER ALLOYS(NICKEL , COBALT,≤ 300 Bhn ≤ 0.2 ≤ APMX (109-163) Feed (ipm) 8 10 11 10 9 8 IRON BASE) or HSM 3xD 141 Fz 0.0007 0.0012 0.0018 0.0021 0.0024 0.0028 Inconel 601, 617, 625, ≤ 32 HRcIncoloy, Monel 400≤ 0.15 ≤ APMX (113-169) Feed (ipm) 9 11 12 11 11 9 HSM 4xD 126 Fz 0.0007 0.0013 0.0018 0.0022 0.0025 0.0029 ≤ 0.1 ≤ APMX (101-151) Feed (ipm) 9 12 12 12 11 10 RPM 1207 805 604 483 402 302 HSMSUPER ALLOYS(NICKEL, COBALT,IRON BASE)Inconel 718, X-750,Incoloy, Waspaloy,≤ 400 BhnorHSM≤ 43 HRc2.5xD85Fz0.00050.00090.00130.00150.00180.0022≤ 0.2≤ APMX(68-102)Feed (ipm)4555553xD88Fz0.00050.00100.00150.00180.00200.0025≤ 0.15≤ APMX(70-106)Feed (ipm)466665 Hastelloy, Rene HSM 4xD 79 Fz 0.0006 0.0011 0.0015 0.0018 0.0021 0.0026 ≤ 0.1 ≤ APMX (63-95) Feed (ipm) 5 6 6 6 6 5 S RPM 4095 2730 2048 1638 1365 1024 HSM 2.5xD 289 Fz 0.0008 0.0015 0.0021 0.0024 0.0028 0.0032 TITANIUM ALLOYSPure Ttanium, Ti6Al4V,Ti6Al2Sn4Zr2Mo,Ti4Al4Mo2Sn0.5Si≤ 350 Bhnor≤ 38 HRcHSM≤ 0.2≤ APMX(231-347)Feed (ipm)23 29 30 28 27 233xD299Fz0.00090.00170.00230.00250.00280.0036≤ 0.15≤ APMX(239-359)Feed (ipm)263233292726 HSM 4xD 268 Fz 0.0009 0.0018 0.0024 0.0029 0.0033 0.0037 ≤ 0.1 ≤ APMX (214-322) Feed (ipm) 26 34 34 33 32 27 RPM 2399 1599 1199 960 800 600 TITANIUM ALLOYS HSM(DIFFICULT)Ti10Al2Fe3Al,Ti5Al5V5Mo3Cr,Ti7Al4Mo,Ti3Al8V6Cr4Zr4Mo,≤ 440 BhnorHSM≤ 47 HRc2.5xD170Fz0.00080.00150.00210.00240.00280.0032≤ 0.2≤ APMX(136-204)Feed (ipm)1317181616133xD176Fz0.00090.00170.00230.00250.00280.0036≤ 0.15≤ APMX(141-211)Feed (ipm)151919171615 Ti6Al6V6Sn,Ti15V3 Cr3Sn3Al HSM 4xD 157 Fz 0.0009 0.0018 0.0024 0.0029 0.0033 0.0037 ≤ 0.1 ≤ APMX (126-188) Feed (ipm) 15 20 20 19 18 16 RPM 3851 2567 1925 1540 1284 963 HSM 2.5xD 272 Fz 0.0006 0.0011 0.0014 0.0017 0.0020 0.0024 ≤ 0.2 ≤ APMX (218-326) Feed (ipm) 16 20 19 18 18 16 TOOL STEELS ≤ 375 Bhn H A2, D2, H13, L2, M2, or HSM 3xD 282 Fz 0.0007 0.0012 0.0016 0.0019 0.0022 0.0027 P20, S7, T15, W2 ≤ 40 HRc ≤ 0.15 ≤ APMX (226-338) Feed (ipm) 19 22 22 20 20 18 HSM 4xD 252 Fz 0.0007 0.0013 0.0017 0.0020 0.0023 0.0028 ≤ 0.1 ≤ APMX (202-302) Feed (ipm) 19 23 23 22 21 19 Bhn (Brinell) HRc (Rockwell C) HSM (High Speed Machining) rpm = Vc x 3.82 / DC mm/min = Fz x 7 x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x DC maximum) feed rates listed have chip thinning adjustments included where applicable refer to the SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 87

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов