Общий каталог SGS 2021 - страница 60

Навигация

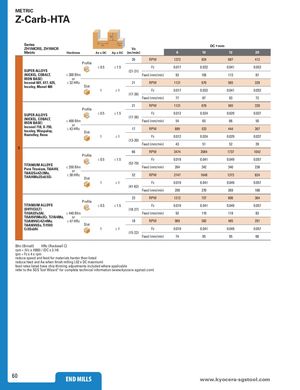

METRIC Z-Carb-HTA Ap Series Ae Ae DC • mm ZH1MCRS, ZH1MCR Vc Metric Hardness Ae x DC Ap x DC (m/min) 6 10 12 20 26 RPM 1373 824 687 412 Profile ≤ 0.5 ≤ 1.5 Fz 0.017 0.032 0.041 0.053 SUPER ALLOYS (21-31) (NICKEL, COBALT, ≤ 300 Bhn Feed (mm/min) 93 105 113 87 IRON BASE) or Inconel 601, 617, 625, ≤ 32 HRc 21 RPM 1131 679 565 339 Incoloy, Monel 400 Slot 1 ≤1 Fz 0.017 0.032 0.041 0.053 (17-26) Feed (mm/min) 77 87 93 72 21 RPM 1131 679 565 339 Profile SUPER ALLOYS(NICKEL, COBALT,IRON BASE)Inconel 718, X-750,Incoloy, Waspaloy,Hastelloy, Rene≤ 0.5≤ 1.5Fz 0.012(17-26)≤ 400 BhnFeed (mm/min)54or≤ 43 HRc17RPM889Slot1≤1Fz0.0120.024655330.0240.029664440.0290.037502670.037 (13-20) Feed (mm/min) 43 51 52 39 S 66 RPM 3474 2084 1737 1042 Profile ≤ 0.5 ≤ 1.5 Fz 0.019 0.041 0.049 0.057 TITANIUM ALLOYSPure Titanium, Ti6Al4V,Ti6Al2Sn4Zr2Mo,Ti4Al4Mo2Sn0.5Si≤ 350 Bhnor≤ 38 HRcSlot(52-79)Feed (mm/min) 264 342 340 23852RPM274716481373824 1 ≤1 Fz 0.019 0.041 0.049 0.057 (41-62) Feed (mm/min) 209 270 269 188 23 RPM 1212 727 606 364 Profile TITANIUM ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.019 0.041 0.049 0.057 (DIFFICULT) (18-27) Ti10Al2Fe3Al, ≤ 440 Bhn Feed (mm/min) 92 119 119 83 Ti5Al5V5Mo3Cr, Ti7Al4Mo, or Ti3Al8V6Cr4Zr4Mo, ≤ 47 HRc 18 RPM 969 582 485 291 Ti6Al6V6Sn, Ti15V3 Slot Cr3Sn3Al 1 ≤1 Fz 0.019 0.041 0.049 0.057 (15-22) Feed (mm/min) 74 95 95 66 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 1000) / (DC x 3.14) ipm = Fz x 4 x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x DC maximum) feed rates listed have chip thinning adjustments included where applicable refer to the SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) 60 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов