Общий каталог SGS 2021 - страница 44

Навигация

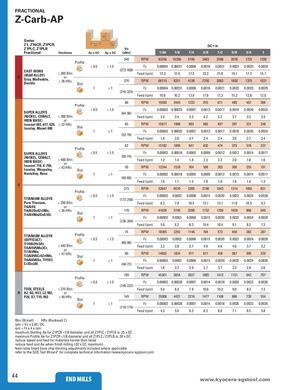

FRACTIONAL Z-Carb-AP Ap Series Z1, Z16CR, Z1PCR, Ae Ae DC • in Z1PLC, Z1PLB Vc Fractional Hardness Ae x DC Ap x DC (sfm) 1/64 1/8 1/4 3/8 1/2 5/8 3/4 1 340 RPM 83256 10390 5195 3463 2598 2078 1732 1299 Profile ≤ 0.5 ≤ 1.5 Fz 0.00004 0.00031 0.0008 0.0016 0.0021 0.0023 0.0025 0.0029 CAST IRONSK(HIGH ALLOY)Gray, Malleable,Ductile≤ 260 Bhnor≤ 26 HRcSlot (272-408) Feed (ipm) 13.3 12.9 17.5 22.2 21.8 19.1 17.3 15.1270RPM661158251412627502063165013751031 1 ≤1 Fz 0.00004 0.00031 0.0008 0.0016 0.0021 0.0023 0.0025 0.0029 (216-324) Feed (ipm) 10.6 10.2 13.9 17.6 17.3 15.2 13.8 12.0 80 RPM 19590 2445 1222 815 611 489 407 306 Profile ≤ 0.5 ≤ 1.5 Fz 0.00003 0.00025 0.0007 0.0013 0.0017 0.0019 0.0020 0.0024 SUPER ALLOYS (64-96) (NICKEL, COBALT, ≤ 300 Bhn Feed (ipm) 2.4 2.4 3.3 4.2 4.2 3.7 3.3 2.9 IRON BASE) or Inconel 601, 617, 625, ≤ 32 HRcIncoloy, Monel 400Slot 65 RPM 15917 1986 993 662 497 397 331 248 1 ≤1 Fz 0.00003 0.00025 0.0007 0.0013 0.0017 0.0019 0.0020 0.0024 (52-78) Feed (ipm) 1.9 2.0 2.7 3.4 3.4 3.0 2.7 2.4 62 RPM 15182 1895 947 632 474 379 316 237 Profile SUPER ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.00002 0.00018 0.0005 0.0009 0.0012 0.0013 0.0014 0.0017 (NICKEL, COBALT,IRON BASE)Inconel 718, X-750,Incoloy, Waspaloy,≤ 400 Bhnor≤ 43 HRcSlot(50-74)Feed (ipm)1.2 1.4 1.8 2.3 2.3 2.0 1.8 1.650RPM122441528764509382306255191 Hastelloy, Rene 1 ≤1 Fz 0.00002 0.00018 0.0005 0.0009 0.0012 0.0013 0.0014 0.0017 (40-60) Feed (ipm) 1.0 1.1 1.5 1.8 1.8 1.6 1.4 1.3 S 215 RPM 52647 6570 3285 2190 1643 1314 1095 821 Profile ≤ 0.5 ≤ 1.5 Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 TITANIUM ALLOYS (172-258) Pure Titanium, ≤ 350 Bhn Feed (ipm) 6.3 7.9 10.5 13.1 13.1 11.6 10.5 9.2 Ti6Al4V, or Ti6Al2Sn4Zr2Mo, ≤ 38 HRc 170 RPM 41628 5195 2598 1732 1299 1039 866 649 Ti4Al4Mo2Sn0.5Si Slot 1 ≤1 Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 (136-204) Feed (ipm) 5.0 6.2 8.3 10.4 10.4 9.1 8.3 7.3 75 RPM 18365 2292 1146 764 573 458 382 287 TITANIUM ALLOYS Profile (DIFFICULT) ≤ 0.5 ≤ 1.5 Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 Ti10Al2Fe3Al,Ti5Al5V5Mo3Cr,Ti7Al4Mo,Ti3Al8V6Cr4Zr4Mo,≤ 440 Bhnor≤ 47 HRcSlot (60-90) Feed (ipm) 2.2 2.8 3.7 4.6 4.6 4.0 3.7 3.260RPM146921834917611458367306229 Ti6Al6V6Sn, Ti15V3 1 ≤1 Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 Cr3Sn3Al (48-72) Feed (ipm) 1.8 2.2 2.9 3.7 3.7 3.2 2.9 2.6 185 RPM 45301 5654 2827 1885 1413 1131 942 707 Profile ≤ 0.5 ≤ 1.5 Fz 0.00003 0.00028 0.0007 0.0014 0.0018 0.0020 0.0022 0.0026 (148-222) TOOL STEELS ≤ 375 Bhn Feed (ipm) 5.4 6.3 7.9 10.6 10.2 9.0 8.3 7.3 H A2, D2, H13, L2, M2, or P20, S7, T15, W2 ≤ 40 HRc 145 RPM 35506 4431 2216 1477 1108 886 739 554 Slot 1 ≤1 Fz 0.00003 0.00028 0.0007 0.0014 0.0018 0.0020 0.0022 0.0026 (116-174) Feed (ipm) 4.3 5.0 6.2 8.3 8.0 7.1 6.5 5.8 Bhn (Brinell) HRc (Rockwell C) rpm = Vc x 3.82 / DC ipm = Fz x 4 x rpm maximum Slotting Ap for Z1PCR <1/8 diameter and all Z1PLC / Z1PLB is .25 x DC maximum Profile Ae for Z1PCR <1/8 diameter and all Z1PLC / Z1PLB is .20 x DC reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x DC maximum) feed rates listed have chip thinning adjustments included where applicable refer to the SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) 44 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов