Общий каталог SGS 2021 - страница 22

Навигация

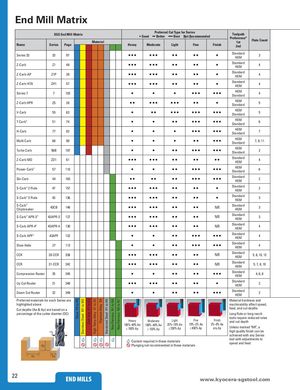

End Mill Matrix SGS End Mill Matrix Material Preferred Cut Type for Series• Good •• Better ••• Best Not RecommendedToolpathPreference*1stFlute Count Name Series Page Heavy Moderate Light Fine Finish 2nd Series 33 33 97 ••• ••• •• •• • StandardHEM 3 Z-Carb Z1 49 ••• ••• •• •• • StandardHEM 4 Z-Carb-AP Z1P 39 ••• ••• •• •• • StandardHEM 4 Z-Carb-HTA ZH1 57 ••• ••• •• •• • StandardHEM 4 Series 7 7 103 • • • ••• ••• HEMStandard 4 Z-Carb HPR Z5 28 •• ••• ••• •• • HEMStandard 5 V-Carb 55 63 • •• ••• ••• ••• HEMStandard 5 T-Carb® 51 74 • • •• ••• ••• HEMStandard 6 H-Carb 77 82 • • • ••• ••• HEMStandard 7 Multi Carb 66 90 • • • •• ••• HEMStandard 7, 9, 11 Turbo Carb 56B 107 • • •• ••• ••• HEMStandard 2 Z-Carb-MD ZD1 61 ••• ••• •• •• •• StandardHEM 4 Power-Carb® 57 110 • • •• ••• ••• HEMStandard 6 Ski-Carb 44 163 •• •• •• ••• ••• StandardHEM 2 S-Carb® 2 Flute 47 157 ••• ••• •• •• • StandardHEM 2 S-Carb® 3 Flute 43 136 ••• ••• •• •• • StandardHEM 3 S-Carb®Chipbreaker 43CB 146 ••• ••• •• •• NR StandardHEM 3 S-Carb® APR-3® 43APR-3 127 ••• ••• •• •• NR StandardHEM 3 S-Carb APR-4® 43APR-4 130 ••• ••• •• •• NR StandardHEM 4 S-Carb APF® 43APF 132 • • •• ••• ••• StandardHEM 4 Slow Helix 27 113 • • •• ••• ••• StandardHEM 4 CCR 20-CCR 338 ••• ••• •• •• NR StandardHEM 5, 8, 10, 12 CCR 31-CCR 342 ••• ••• •• •• NR StandardHEM 5, 7, 8, 10 Compression Router 25 345 • • •• •• ••• StandardHEM 4, 6, 8 Up Cut Router 21 348 ••• ••• •• •• • StandardHEM 2 Down Cut Router 22 349 • • •• •• ••• StandardHEM 2 Preferred materials for each Series are Material hardness and highlighted above machinability affect speed, Cut depths (Ae & Ap) are based on a feed, and cut depths percentage of the cutter diamter (DC) Long flute or long reach tools require reduced rates Heavy Moderate Light Fine100%~40% Ae100%~40% Ae25%~10% Ae10%~2% Ae≤ 100% Ap≤ 150% Ap≤ 250% Ap≤ 450% ApFinish2%~0% Aeand cut depthany ApUnless marked "NR", ahigh quality finish can be achieved with any Series Coolant required in these materialsPlunging not recommended in these materialstool with adjustments tospeed and feed 22 END MILLS wwwE.kNyDoMceILraLS-sgstool.com Steel P0 to P6 Stainless Steel M1 to M3 Cast Iron K1 to K3 High Temp Alloy S1 to S3 Titanium Alloy S4 Hardened Steel H1 to H4 Non Ferrous N1 to N4 Non Ferrous N5 to N7

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов