Общий каталог SGS 2021 - страница 117

Навигация

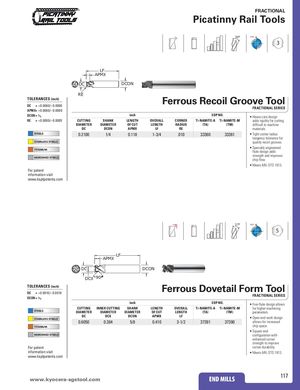

FRACTIONAL Picatinny Rail Tools 35° POS 3 LF APMX DC DCON RE TOLERANCES (inch) Ferrous Recoil Groove Tool DC = +0.0080/–0.0000APMX= +0.0060/–0.0000 FRACTIONAL SERIES DCON = h6 inch EDP NO. • Heavy core design RE = +0.0000/–0.0005 CUTTING SHANK LENGTH OVERALL CORNER Ti-NAMITE-A Ti-NAMITE-M adds rigidity for cutting DIAMETER DIAMETER OF CUT LENGTH RADIUS (TA) (TM) difficult to machine DC DCON APMX LF RE materials. STEELS 0.2100 1/4 0.118 1-3/4 .010 33360 33361 • Tight corner radius tangency tolerance for STAINLESS STEELS quality recoil grooves. TITANIUM • Specially engineeredflute design adds HARDENED STEELS strength and improveschip flow. • Meets MIL-STD 1913. For patent information visit www.ksptpatents.com 37° POS 5 LF APMX DC DCON DCX 90° TOLERANCES (inch) Ferrous Dovetail Form Tool DC = +0.0010/–0.0010 DCON = h6 FRACTIONAL SERIES inch EDP NO. • Five-flute design allows CUTTING INNER CUTTING SHANK LENGTH OVERALL Ti-NAMITE-A Ti-NAMITE-M for higher machining STEELS DIAMETER DIAMETER DIAMETER OF CUT LENGTH (TA) (TM) parameters. DC DCX DCON APMX LFSTAINLESS STEELS • Open end work design 0.6050 0.384 5/8 0.410 3-1/2 37391 37390 allows for increased TITANIUM chip space. • Square end HARDENED STEELS configuration with enhanced corner strength to improve For patent corner durability. information visit • Meets MIL-STD 1913. www.ksptpatents.com www.kyocerEaN-DsgMstILoLoSl.com END MILLS 117

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов