Общий каталог SGS 2021 - страница 102

Навигация

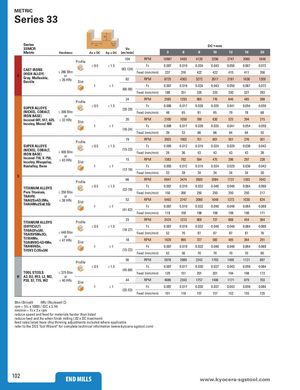

METRIC Series 33 Ap Series Ae Ae DC • mm 33MCR Vc Metric Hardness Ae x DC Ap x DC (m/min) 3 6 8 10 12 16 20 Profile 104 RPM 10987 5493 4120 3296 2747 2060 1648 ≤ 0.5 ≤ 1.5 Fz 0.007 0.019 0.034 0.043 0.050 0.067 0.072 CAST IRONSK(HIGH ALLOY)Gray, Malleable,Ductile≤ 260 Bhnor≤ 26 HRcSlot (83-124) Feed (mm/min) 237 316 422 422 415 411 35682RPM8725436232722617218116361309 1 ≤1 Fz 0.007 0.019 0.034 0.043 0.050 0.067 0.072 (66-99) Feed (mm/min) 188 251 335 335 330 327 283 Profile 24 RPM 2585 1293 969 776 646 485 388 SUPER ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.006 0.017 0.028 0.035 0.041 0.054 0.059(20-29) (NICKEL, COBALT, ≤ 300 Bhn Feed (mm/min) 48 65 81 65 79 78 68 IRON BASE) or Inconel 601, 617, 625, ≤ 32 HRcIncoloy, Monel 400Slot1 20≤1 RPM 2100 1050 788 630 525 394 315Fz0.0060.0170.0280.0350.0410.0540.059 (16-24) Feed (mm/min) 39 53 66 66 64 64 55 Profile 19 RPM 2003 1002 751 601 501 376 301 SUPER ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.005 0.012 0.019 0.024 0.029 0.038 0.043 (NICKEL, COBALT,IRON BASE)Inconel 718, X-750,Incoloy, Waspaloy,≤ 400 Bhnor≤ 43 HRcSlot(15-23)Feed (mm/min) 29 36 43 43 43 43 3815RPM1583792594475396297238 Hastelloy, Rene 1 ≤1 Fz 0.005 0.012 0.019 0.024 0.029 0.038 0.043 (12-18) Feed (mm/min) 23 28 34 34 34 34 30 S Profile 66 RPM 6947 3474 2605 2084 1737 1303 1042 TITANIUM ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069(52-79) Pure Titanium, ≤ 350 Bhn Feed (mm/min) 150 200 250 250 250 250 217 Ti6Al4V, or Ti6Al2Sn4Zr2Mo,Ti4Al4Mo2Sn0.5Si≤ 38 HRcSlot 1 52≤1 RPM 5493 2747 2060 1648 1373 1030 824Fz0.0070.0190.0320.0400.0480.0640.069 (41-62) Feed (mm/min) 119 158 198 198 198 198 171 TITANIUM ALLOYS Profile 23 RPM 2424 1212 909 727 606 454 364 (DIFFICULT) ≤ 0.5 ≤ 1.5 Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 Ti10Al2Fe3Al,Ti5Al5V5Mo3Cr,Ti7Al4Mo,Ti3Al8V6Cr4Zr4Mo,≤ 440 Bhnor≤ 47 HRcSlot (18-27) Feed (mm/min) 52 70 87 87 87 87 7618RPM1939969727582485364291 Ti6Al6V6Sn, 1 ≤1 Fz 0.007 0.019 0.032 0.040 0.048 0.064 0.069 Ti15V3 Cr3Sn3Al (15-22) Feed (mm/min) 42 56 70 70 70 70 60 Profile 56 RPM 5978 2989 2242 1793 1495 1121 897 ≤ 0.5 ≤ 1.5 Fz 0.007 0.017 0.030 0.037 0.043 0.059 0.064 (45-68) TOOL STEELS ≤ 375 Bhn Feed (mm/min) 129 151 201 201 194 198 172 H A2, D2, H13, L2, M2, or P20, S7, T15, W2 ≤ 40 HRc Slot 44 RPM 4686 2343 1757 1406 1171 879 703 1 ≤1 Fz 0.007 0.017 0.030 0.037 0.043 0.059 0.064 (35-53) Feed (mm/min) 101 118 157 157 152 155 135 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 1000) / (DC x 3.14) mm/min = Fz x 3 x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x DC maximum) feed rates listed have chip thinning adjustments included where applicable refer to the SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) 102 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов