Общий каталог SGS 2018 - страница 65

Навигация

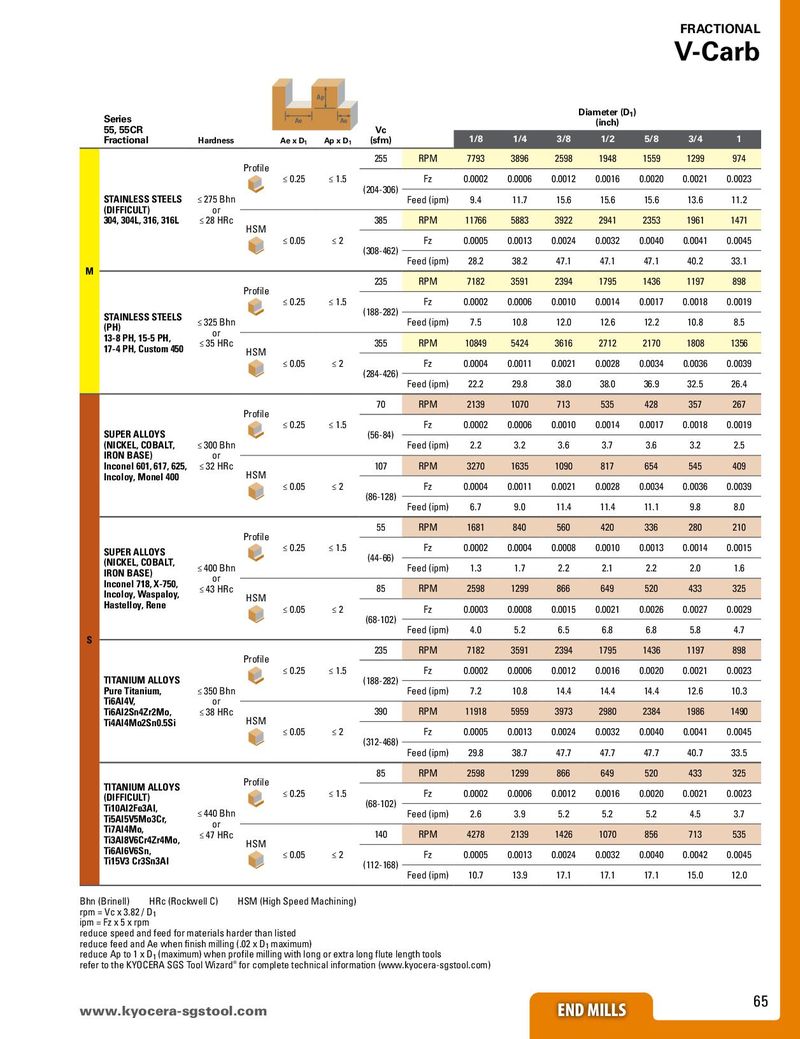

FRACTIONAL V-Carb Ap Series Diameter (D1) Ae Ae (inch) 55, 55CR Vc Fractional Hardness Ae x D1 Ap x D1 (sfm) 1/8 1/4 3/8 1/2 5/8 3/4 1 255 RPM 7793 3896 2598 1948 1559 1299 974 Profile ≤ 0.25 ≤ 1.5 Fz 0.0002 0.0006 0.0012 0.0016 0.0020 0.0021 0.0023 (204-306) STAINLESS STEELS ≤ 275 Bhn Feed (ipm) 9.4 11.7 15.6 15.6 15.6 13.6 11.2 (DIFFICULT) or 304, 304L, 316, 316L ≤ 28 HRc 385 RPM 11766 5883 3922 2941 2353 1961 1471 HSM ≤ 0.05 ≤2 Fz 0.0005 0.0013 0.0024 0.0032 0.0040 0.0041 0.0045 (308-462) Feed (ipm) 28.2 38.2 47.1 47.1 47.1 40.2 33.1 M 235 RPM 7182 3591 2394 1795 1436 1197 898 Profile ≤ 0.25 ≤ 1.5 Fz 0.0002 0.0006 0.0010 0.0014 0.0017 0.0018 0.0019 STAINLESS STEELS (188-282) (PH) ≤ 325 Bhn Feed (ipm) 7.5 10.8 12.0 12.6 12.2 10.8 8.5 13-8 PH, 15-5 PH, or 17-4 PH, Custom 450 ≤ 35 HRc 355 RPM 10849 5424 3616 2712 2170 1808 1356 HSM ≤ 0.05 ≤2 Fz 0.0004 0.0011 0.0021 0.0028 0.0034 0.0036 0.0039 (284-426) Feed (ipm) 22.2 29.8 38.0 38.0 36.9 32.5 26.4 70 RPM 2139 1070 713 535 428 357 267 Profile ≤ 0.25 ≤ 1.5 Fz 0.0002 0.0006 0.0010 0.0014 0.0017 0.0018 0.0019 SUPER ALLOYS (56-84) (NICKEL, COBALT, ≤ 300 Bhn Feed (ipm) 2.2 3.2 3.6 3.7 3.6 3.2 2.5 IRON BASE) or Inconel 601, 617, 625, ≤ 32 HRc 107 RPM 3270 1635 1090 817 654 545 409 Incoloy, Monel 400 HSM ≤ 0.05 ≤2 Fz 0.0004 0.0011 0.0021 0.0028 0.0034 0.0036 0.0039 (86-128) Feed (ipm) 6.7 9.0 11.4 11.4 11.1 9.8 8.0 55 RPM 1681 840 560 420 336 280 210 Profile SUPER ALLOYS ≤ 0.25 ≤ 1.5 Fz 0.0002 0.0004 0.0008 0.0010 0.0013 0.0014 0.0015 (NICKEL, COBALT, (44-66) IRON BASE) ≤ 400 Bhn Feed (ipm) 1.3 1.7 2.2 2.1 2.2 2.0 1.6 Inconel 718, X-750, or Incoloy, Waspaloy, ≤ 43 HRc 85 RPM 2598 1299 866 649 520 433 325 Hastelloy, Rene HSM ≤ 0.05 ≤2 Fz 0.0003 0.0008 0.0015 0.0021 0.0026 0.0027 0.0029 (68-102) Feed (ipm) 4.0 5.2 6.5 6.8 6.8 5.8 4.7 S 235 RPM 7182 3591 2394 1795 1436 1197 898 Profile ≤ 0.25 ≤ 1.5 Fz 0.0002 0.0006 0.0012 0.0016 0.0020 0.0021 0.0023 TITANIUM ALLOYS (188-282) Pure Titanium, ≤ 350 Bhn Feed (ipm) 7.2 10.8 14.4 14.4 14.4 12.6 10.3 Ti6Al4V, or Ti6Al2Sn4Zr2Mo, ≤ 38 HRc 390 RPM 11918 5959 3973 2980 2384 1986 1490 Ti4Al4Mo2Sn0.5Si HSM ≤ 0.05 ≤2 Fz 0.0005 0.0013 0.0024 0.0032 0.0040 0.0041 0.0045 (312-468) Feed (ipm) 29.8 38.7 47.7 47.7 47.7 40.7 33.5 85 RPM 2598 1299 866 649 520 433 325 TITANIUM ALLOYS Profile (DIFFICULT) ≤ 0.25 ≤ 1.5 Fz 0.0002 0.0006 0.0012 0.0016 0.0020 0.0021 0.0023 Ti10Al2Fe3Al, (68-102) Ti5Al5V5Mo3Cr, ≤ 440 Bhn Feed (ipm) 2.6 3.9 5.2 5.2 5.2 4.5 3.7 Ti7Al4Mo, or Ti3Al8V6Cr4Zr4Mo, ≤ 47 HRc 140 RPM 4278 2139 1426 1070 856 713 535 Ti6Al6V6Sn, HSM Ti15V3 Cr3Sn3Al ≤ 0.05 ≤2 Fz 0.0005 0.0013 0.0024 0.0032 0.0040 0.0042 0.0045 (112-168) Feed (ipm) 10.7 13.9 17.1 17.1 17.1 15.0 12.0 Bhn (Brinell) HRc (Rockwell C) HSM (High Speed Machining) rpm = Vc x 3.82 / D1 ipm = Fz x 5 x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x D1 maximum) reduce Ap to 1 x D1 (maximum) when profile milling with long or extra long flute length tools refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 65

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском