Общий каталог SGS 2018 - страница 50

Навигация

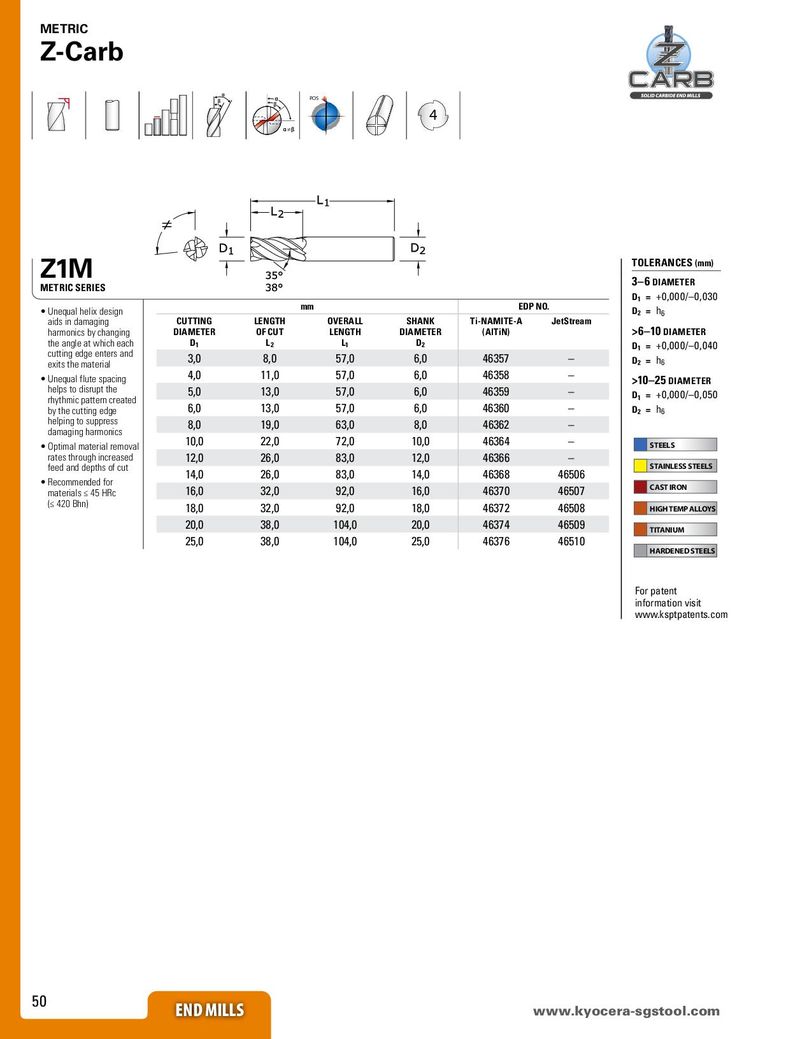

METRIC Z-Carb POS 4 ≠ Z1M TOLERANCES (mm) METRIC SERIES 3–6 DIAMETER D1 = +0,000/–0,030 • Unequal helix design mm EDP NO. D2 = h6 aids in damaging CUTTING LENGTH OVERALL SHANK Ti-NAMITE-A JetStream >6–10 DIAMETER harmonics by changing DIAMETER OF CUT LENGTH DIAMETER (AlTiN) the angle at which each D1 L2 L1 D2 D1 = +0,000/–0,040 cutting edge enters and 3,0 8,0 57,0 6,0 46357 – D2 = h6 exits the material • Unequal flute spacing 4,0 11,0 57,0 6,0 46358 – >10–25 DIAMETER helps to disrupt the 5,0 13,0 57,0 6,0 46359 – D1 = +0,000/–0,050 rhythmic pattern created 6,0 13,0 57,0 6,0 46360 – h6 by the cutting edge D2 = helping to suppress 8,0 19,0 63,0 8,0 46362 – damaging harmonics 10,0 22,0 72,0 10,0 46364 – • Optimal material removal STEELS rates through increased 12,0 26,0 83,0 12,0 46366 – feed and depths of cut 14,0 26,0 83,0 14,0 46368 46506 STAINLESS STEELS • Recommended for 16,0 32,0 92,0 16,0 46370 46507 CAST IRON materials ≤ 45 HRc (≤ 420 Bhn) 18,0 32,0 92,0 18,0 46372 46508 HIGH TEMP ALLOYS 20,0 38,0 104,0 20,0 46374 46509 TITANIUM 25,0 38,0 104,0 25,0 46376 46510 HARDENED STEELS For patent information visit www.ksptpatents.com 50 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском