Общий каталог SGS 2018 - страница 31

Навигация

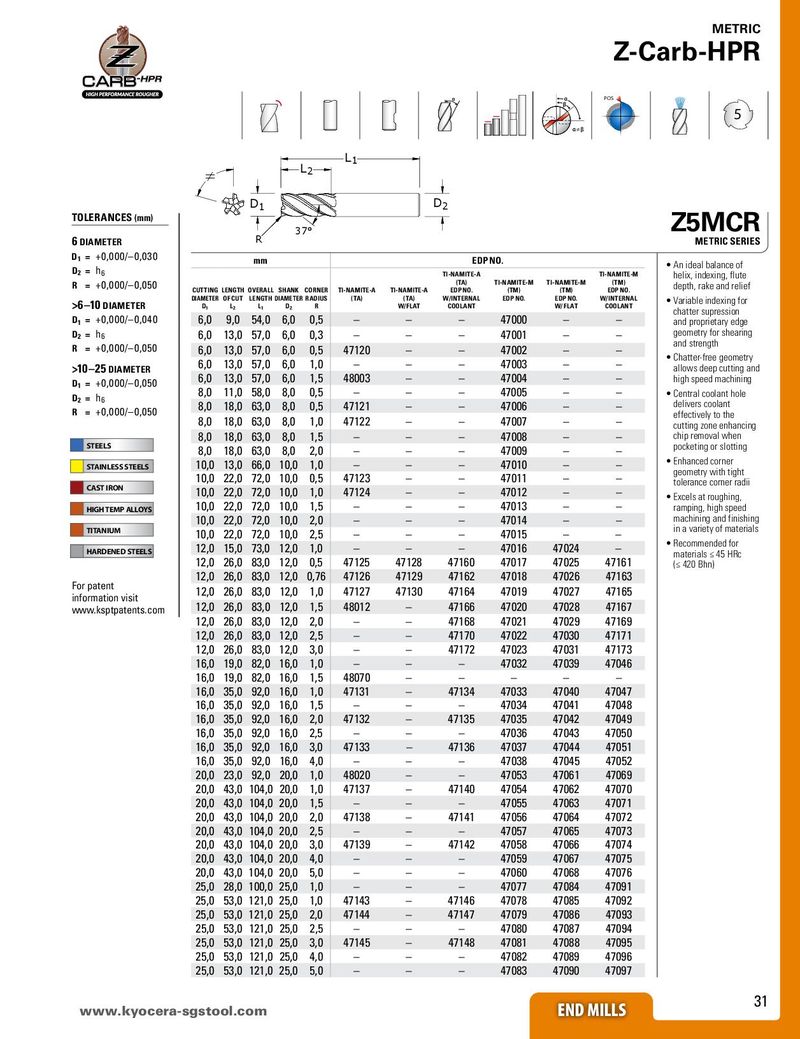

METRIC Z-Carb-HPR POS 5 ≠ L2 L1 D1 D2 TOLERANCES (mm) Z5MCR R 37° 6 DIAMETER METRIC SERIES D1 = +0,000/–0,030 mm EDP NO. • An ideal balance of D2 = h6 TI-NAMITE-A TI-NAMITE-M helix, indexing, flute R = +0,000/–0,050 (TA) TI-NAMITE-M TI-NAMITE-M (TM) depth, rake and relief CUTTING LENGTH OVERALL SHANK CORNER TI-NAMITE-A TI-NAMITE-A EDP NO. (TM) (TM) EDP NO. >6–10 DIAMETER DIAMETER OF CUT LENGTH DIAMETER RADIUS (TA) (TA) W/INTERNAL EDP NO. EDP NO. W/INTERNAL • Variable indexing for D1 L2 L1 D2 R W/FLAT COOLANT W/ FLAT COOLANT chatter supression D1 = +0,000/–0,040 6,0 9,0 54,0 6,0 0,5 – – – 47000 – – and proprietary edge D2 = h6 6,0 13,0 57,0 6,0 0,3 – – – 47001 – – geometry for shearing R = +0,000/–0,050 6,0 13,0 57,0 6,0 0,5 47120 – – 47002 – – and strength 6,0 13,0 57,0 6,0 1,0 – – – 47003 – – • Chatter-free geometry >10–25 DIAMETER allows deep cutting and D1 = +0,000/–0,050 6,0 13,0 57,0 6,0 1,5 48003 – – 47004 – – high speed machining D2 = h6 8,0 11,0 58,0 8,0 0,5 – – – 47005 – – • Central coolant hole R = +0,000/–0,050 8,0 18,0 63,0 8,0 0,5 47121 – – 47006 – – delivers coolant 8,0 18,0 63,0 8,0 1,0 47122 – – 47007 – – effectively to the cutting zone enhancing 8,0 18,0 63,0 8,0 1,5 – – – 47008 – – chip removal when STEELS 8,0 18,0 63,0 8,0 2,0 – – – 47009 – – pocketing or slotting STAINLESS STEELS 10,0 13,0 66,0 10,0 1,0 – – – 47010 – – • Enhanced corner 10,0 22,0 72,0 10,0 0,5 47123 – – 47011 – – geometry with tight CAST IRON tolerance corner radii 10,0 22,0 72,0 10,0 1,0 47124 – – 47012 – – • Excels at roughing, HIGH TEMP ALLOYS 10,0 22,0 72,0 10,0 1,5 – – – 47013 – – ramping, high speed 10,0 22,0 72,0 10,0 2,0 – – – 47014 – – machining and finishing TITANIUM 10,0 22,0 72,0 10,0 2,5 – – – 47015 – – in a variety of materials 12,0 15,0 73,0 12,0 1,0 – – – 47016 47024 – • Recommended for HARDENED STEELS materials ≤ 45 HRc 12,0 26,0 83,0 12,0 0,5 47125 47128 47160 47017 47025 47161 (≤ 420 Bhn) For patent 12,0 26,0 83,0 12,0 0,76 47126 47129 47162 47018 47026 47163 information visit 12,0 26,0 83,0 12,0 1,0 47127 47130 47164 47019 47027 47165 www.ksptpatents.com 12,0 26,0 83,0 12,0 1,5 48012 – 47166 47020 47028 47167 12,0 26,0 83,0 12,0 2,0 – – 47168 47021 47029 47169 12,0 26,0 83,0 12,0 2,5 – – 47170 47022 47030 47171 12,0 26,0 83,0 12,0 3,0 – – 47172 47023 47031 47173 16,0 19,0 82,0 16,0 1,0 – – – 47032 47039 47046 16,0 19,0 82,0 16,0 1,5 48070 – – – – – 16,0 35,0 92,0 16,0 1,0 47131 – 47134 47033 47040 47047 16,0 35,0 92,0 16,0 1,5 – – – 47034 47041 47048 16,0 35,0 92,0 16,0 2,0 47132 – 47135 47035 47042 47049 16,0 35,0 92,0 16,0 2,5 – – – 47036 47043 47050 16,0 35,0 92,0 16,0 3,0 47133 – 47136 47037 47044 47051 16,0 35,0 92,0 16,0 4,0 – – – 47038 47045 47052 20,0 23,0 92,0 20,0 1,0 48020 – – 47053 47061 47069 20,0 43,0 104,0 20,0 1,0 47137 – 47140 47054 47062 47070 20,0 43,0 104,0 20,0 1,5 – – – 47055 47063 47071 20,0 43,0 104,0 20,0 2,0 47138 – 47141 47056 47064 47072 20,0 43,0 104,0 20,0 2,5 – – – 47057 47065 47073 20,0 43,0 104,0 20,0 3,0 47139 – 47142 47058 47066 47074 20,0 43,0 104,0 20,0 4,0 – – – 47059 47067 47075 20,0 43,0 104,0 20,0 5,0 – – – 47060 47068 47076 25,0 28,0 100,0 25,0 1,0 – – – 47077 47084 47091 25,0 53,0 121,0 25,0 1,0 47143 – 47146 47078 47085 47092 25,0 53,0 121,0 25,0 2,0 47144 – 47147 47079 47086 47093 25,0 53,0 121,0 25,0 2,5 – – – 47080 47087 47094 25,0 53,0 121,0 25,0 3,0 47145 – 47148 47081 47088 47095 25,0 53,0 121,0 25,0 4,0 – – – 47082 47089 47096 25,0 53,0 121,0 25,0 5,0 – – – 47083 47090 47097 www.kyocerEaN-DsgMstILoLoSl.com END MILLS 31

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском