Общий каталог SGS 2018 - страница 244

Навигация

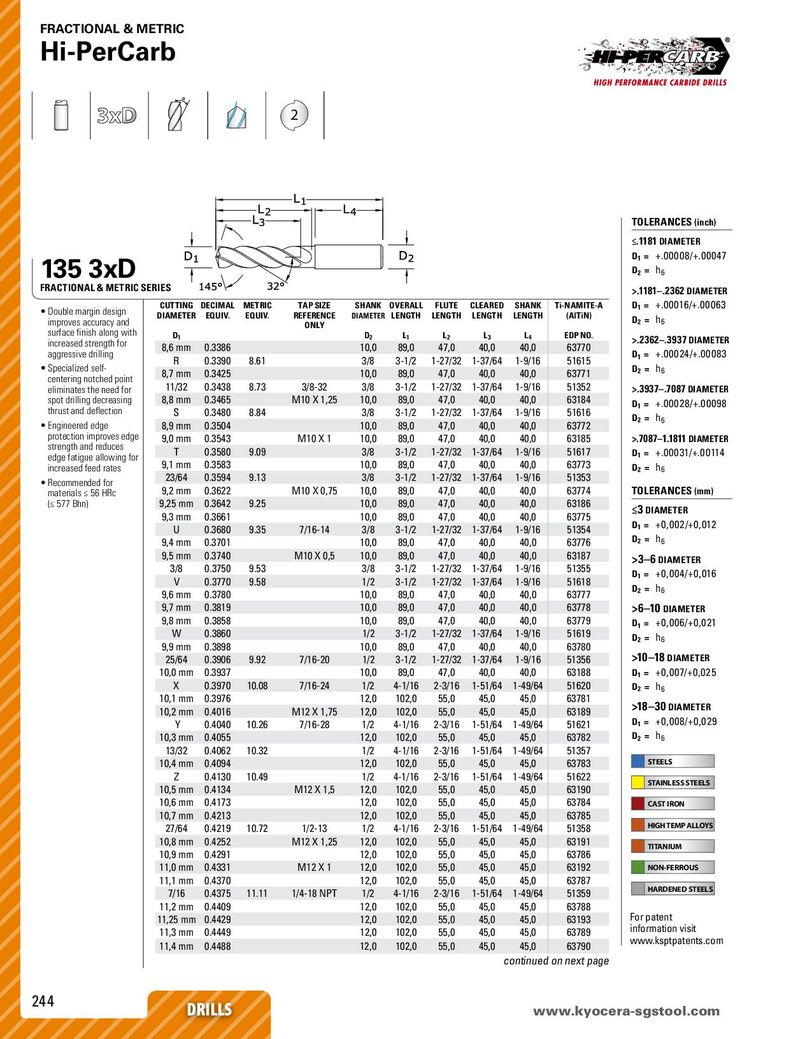

FRACTIONAL & METRIC Hi-PerCarb 2 TOLERANCES (inch) ≤.1181 DIAMETER 135 3xD D1 = +.00008/+.00047 D2 = h6 FRACTIONAL & METRIC SERIES >.1181–.2362 DIAMETER • Double margin design CUTTING DECIMAL METRIC TAP SIZE SHANK OVERALL FLUTE CLEARED SHANK Ti-NAMITE-A D1 = +.00016/+.00063 improves accuracy and DIAMETER EQUIV. EQUIV. REFERENCE DIAMETER LENGTH LENGTH LENGTH LENGTH (AlTiN) D2 = h6 surface finish along with ONLY increased strength for D1 D2 L1 L2 L3 L4 EDP NO. >.2362–.3937 DIAMETER aggressive drilling 8,6 mm 0.3386 10,0 89,0 47,0 40,0 40,0 63770 D1 = +.00024/+.00083 • Specialized self- R 0.3390 8.61 3/8 3-1/2 1-27/32 1-37/64 1-9/16 51615 D2 = h6 centering notched point 8,7 mm 0.3425 10,0 89,0 47,0 40,0 40,0 63771 eliminates the need for 11/32 0.3438 8.73 3/8-32 3/8 3-1/2 1-27/32 1-37/64 1-9/16 51352 >.3937–.7087 DIAMETER spot drilling decreasing 8,8 mm 0.3465 M10 X 1,25 10,0 89,0 47,0 40,0 40,0 63184 D1 = +.00028/+.00098 thrust and deflection S 0.3480 8.84 3/8 3-1/2 1-27/32 1-37/64 1-9/16 51616 D2 = h6 • Engineered edge 8,9 mm 0.3504 10,0 89,0 47,0 40,0 40,0 63772 protection improves edge 9,0 mm 0.3543 M10 X 1 10,0 89,0 47,0 40,0 40,0 63185 >.7087–1.1811 DIAMETER strength and reduces T 0.3580 9.09 3/8 3-1/2 1-27/32 1-37/64 1-9/16 51617 D1 = +.00031/+.00114 edge fatigue allowing for 9,1 mm 0.3583 10,0 89,0 47,0 40,0 40,0 63773 increased feed rates D2 = h6 • Recommended for 23/64 0.3594 9.13 3/8 3-1/2 1-27/32 1-37/64 1-9/16 51353 materials ≤ 56 HRc 9,2 mm 0.3622 M10 X 0,75 10,0 89,0 47,0 40,0 40,0 63774 TOLERANCES (mm) (≤ 577 Bhn) 9,25 mm 0.3642 9.25 10,0 89,0 47,0 40,0 40,0 63186 ≤3 DIAMETER 9,3 mm 0.3661 10,0 89,0 47,0 40,0 40,0 63775 D1 = + 0, 0 0 2 /+ 0, 012 U 0.3680 9.35 7/16-14 3/8 3-1/2 1-27/32 1-37/64 1-9/16 51354 h6 9,4 mm 0.3701 10,0 89,0 47,0 40,0 40,0 63776 D2 = 9,5 mm 0.3740 M10 X 0,5 10,0 89,0 47,0 40,0 40,0 63187 >3–6 DIAMETER 3/8 0.3750 9.53 3/8 3-1/2 1-27/32 1-37/64 1-9/16 51355 D1 = +0,004/+0,016 V 0.3770 9.58 1/2 3-1/2 1-27/32 1-37/64 1-9/16 51618 D2 = h6 9,6 mm 0.3780 10,0 89,0 47,0 40,0 40,0 63777 9,7 mm 0.3819 10,0 89,0 47,0 40,0 40,0 63778 >6–10 DIAMETER 9,8 mm 0.3858 10,0 89,0 47,0 40,0 40,0 63779 D1 = +0,006/+0,021 W 0.3860 1/2 3-1/2 1-27/32 1-37/64 1-9/16 51619 D2 = h6 9,9 mm 0.3898 10,0 89,0 47,0 40,0 40,0 63780 25/64 0.3906 9.92 7/16-20 1/2 3-1/2 1-27/32 1-37/64 1-9/16 51356 >10–18 DIAMETER 10,0 mm 0.3937 10,0 89,0 47,0 40,0 40,0 63188 D1 = +0,007/+0,025 X 0.3970 10.08 7/16-24 1/2 4-1/16 2-3/16 1-51/64 1-49/64 51620 D2 = h6 10,1 mm 0.3976 12,0 102,0 55,0 45,0 45,0 63781 >18–30 DIAMETER 10,2 mm 0.4016 M12 X 1,75 12,0 102,0 55,0 45,0 45,0 63189 +0,008/+0,029 Y 0.4040 10.26 7/16-28 1/2 4-1/16 2-3/16 1-51/64 1-49/64 51621 D1 = 10,3 mm 0.4055 12,0 102,0 55,0 45,0 45,0 63782 D2 = h6 13/32 0.4062 10.32 1/2 4-1/16 2-3/16 1-51/64 1-49/64 51357 10,4 mm 0.4094 12,0 102,0 55,0 45,0 45,0 63783 STEELS Z 0.4130 10.49 1/2 4-1/16 2-3/16 1-51/64 1-49/64 51622 STAINLESS STEELS 10,5 mm 0.4134 M12 X 1,5 12,0 102,0 55,0 45,0 45,0 63190 10,6 mm 0.4173 12,0 102,0 55,0 45,0 45,0 63784 CAST IRON 10,7 mm 0.4213 12,0 102,0 55,0 45,0 45,0 63785 27/64 0.4219 10.72 1/2-13 1/2 4-1/16 2-3/16 1-51/64 1-49/64 51358 HIGH TEMP ALLOYS 10,8 mm 0.4252 M12 X 1,25 12,0 102,0 55,0 45,0 45,0 63191 TITANIUM 10,9 mm 0.4291 12,0 102,0 55,0 45,0 45,0 63786 11,0 mm 0.4331 M12 X 1 12,0 102,0 55,0 45,0 45,0 63192 NON-FERROUS 11,1 mm 0.4370 12,0 102,0 55,0 45,0 45,0 63787 7/16 0.4375 11.11 1/4-18 NPT 1/2 4-1/16 2-3/16 1-51/64 1-49/64 51359 HARDENED STEELS 11,2 mm 0.4409 12,0 102,0 55,0 45,0 45,0 63788 11,25 mm 0.4429 12,0 102,0 55,0 45,0 45,0 63193 For patent 11,3 mm 0.4449 12,0 102,0 55,0 45,0 45,0 63789 information visit 11,4 mm 0.4488 12,0 102,0 55,0 45,0 45,0 63790 www.ksptpatents.com continued on next page 244 DRILLS www.kDyRoIcLeLrSa-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском