Общий каталог SGS 2018 - страница 237

Навигация

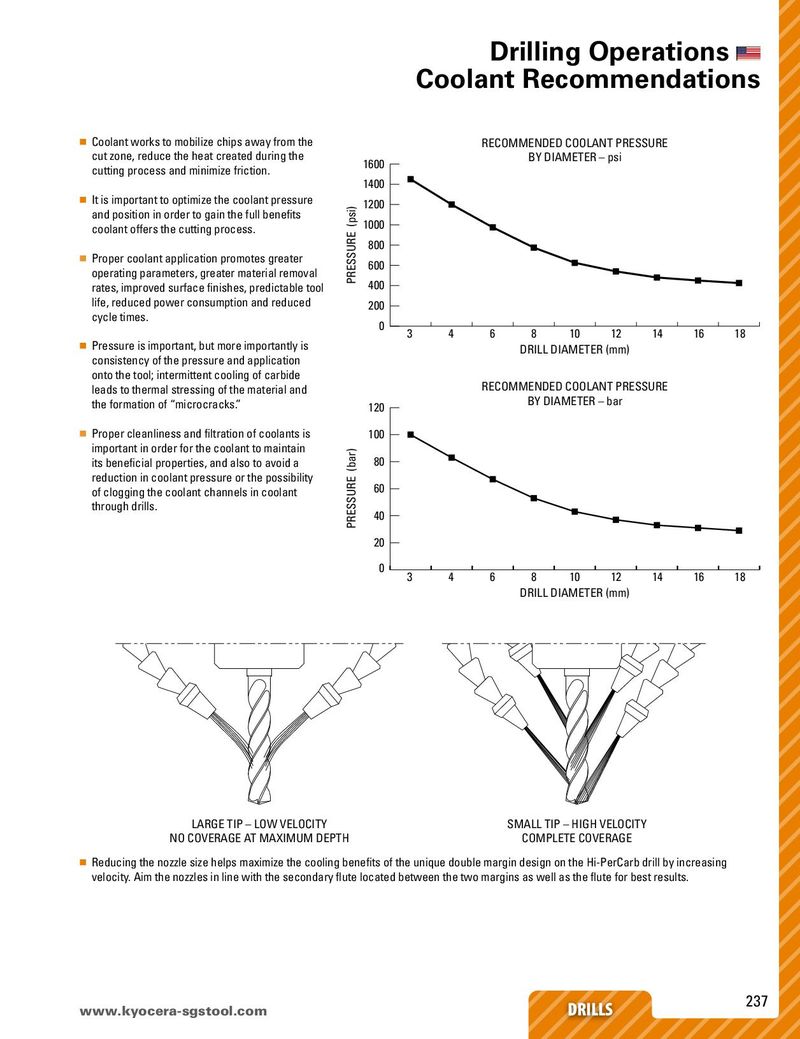

Drilling Operations SGS CSOGOSLCAONOTLRAENCTORMEMCOENMDMAETNIODNASTIONS Coolant Recommendations ◾ Coolant works to mobilize chips away from the RECOMRMECEONMDEMDECNODOELDACNOTOPLRAENSTSPURREESSURE cut zone, reduce the heat created during the 1600 1600 BY DIABMYEDTIEARM–EpTsEiR – psi cutting process and minimize friction. 1400 1400 ◾ It is important to optimize the coolant pressure PRESSURE (psi) 1200 1200 PRESSURE (psi) and position in order to gain the full benefits 1000 1000 coolant offers the cutting process. 800 800 ◾ Proper coolant application promotes greater 600 600 operating parameters, greater material removal 400 rates, improved surface finishes, predictable tool 400 life, reduced power consumption and reduced 200 200 cycle times. 0 30 3 4 46 68 8 10 1012 1214 1416 1618 18 ◾ Pressure is important, but more importantly is DRILL DDIRAIMLLEDTIEARM(mETmE)R (mm) consistency of the pressure and application onto the tool; intermittent cooling of carbide RECOMRMECEONMDEMDECNODOELDACNOTOPLRAENSTSPURREESSURE leads to thermal stressing of the material and BY DIABMYEDTIEARM–EbTaErR – bar the formation of “microcracks.” 120 120 ◾ Proper cleanliness and filtration of coolants is 100 100 important in order for the coolant to maintain PRESSURE (bar) 80PRESSURE (bar) its beneficial properties, and also to avoid a 80 reduction in coolant pressure or the possibility 60 of clogging the coolant channels in coolant 60 through drills. 40 40 20 20 0 30 4 46 68 8 10 1012 1214 1416 1618 3 18 DRILL DDIRAIMLLEDTIEARM(mETmE)R (mm) LARGELTAIRPG–ELTOIWP –VLEOLOWCVITEYLOCITY SMALLSTMIPAL–LHTIIGPH–VHEILGOHCVITEYLOCITY NO COVNEORCAOGVEEARTAMGEAAXTIMMUAMXIDMEUPMTHDEPTH COMPLCEOTME PCLOEVTEERCAOGVEERAGE ◾ Reducing the nozzle size helps maximize the cooling benefits of the unique double margin design on the Hi-PerCarb drill by increasing velocity. Aim the nozzles in line with the secondary flute located between the two margins as well as the flute for best results. www.kyoceraD-sRgILsLtoSol.com DRILLS 237

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском