Общий каталог SGS 2018 - страница 233

Навигация

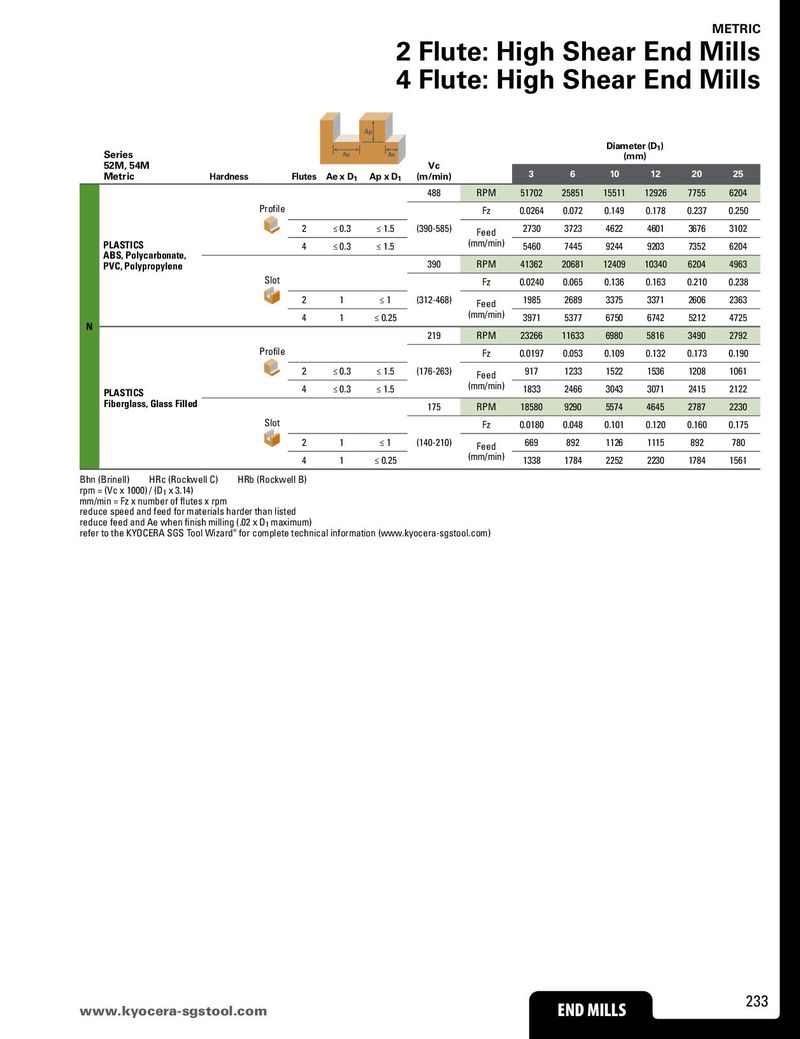

METRIC 2 Flute: High Shear End Mills 4 Flute: High Shear End Mills Ap Series Diameter (D1) Ae Ae (mm) 52M, 54M Vc 3 6 10 12 20 25 Metric Hardness Flutes Ae x D1 Ap x D1 (m/min) 488 RPM 51702 25851 15511 12926 7755 6204 Profile Fz 0.0264 0.072 0.149 0.178 0.237 0.250 2 ≤ 0.3 ≤ 1.5 (390-585) Feed 2730 3723 4622 4601 3676 3102 PLASTICS 4 ≤ 0.3 ≤ 1.5 (mm/min) 5460 7445 9244 9203 7352 6204 ABS, Polycarbonate, 390 RPM 41362 20681 12409 10340 6204 4963 PVC, Polypropylene Slot Fz 0.0240 0.065 0.136 0.163 0.210 0.238 2 1 ≤1 (312-468) Feed 1985 2689 3375 3371 2606 2363 4 1 ≤ 0.25 (mm/min) 3971 5377 6750 6742 5212 4725 N 219 RPM 23266 11633 6980 5816 3490 2792 Profile Fz 0.0197 0.053 0.109 0.132 0.173 0.190 2 ≤ 0.3 ≤ 1.5 (176-263) Feed 917 1233 1522 1536 1208 1061 PLASTICS 4 ≤ 0.3 ≤ 1.5 (mm/min) 1833 2466 3043 3071 2415 2122 Fiberglass, Glass Filled 175 RPM 18580 9290 5574 4645 2787 2230 Slot Fz 0.0180 0.048 0.101 0.120 0.160 0.175 2 1 ≤1 (140-210) Feed 669 892 1126 1115 892 780 4 1 ≤ 0.25 (mm/min) 1338 1784 2252 2230 1784 1561 Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x number of flutes x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x D1 maximum) refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 23 3

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском