Общий каталог SGS 2018 - страница 229

Навигация

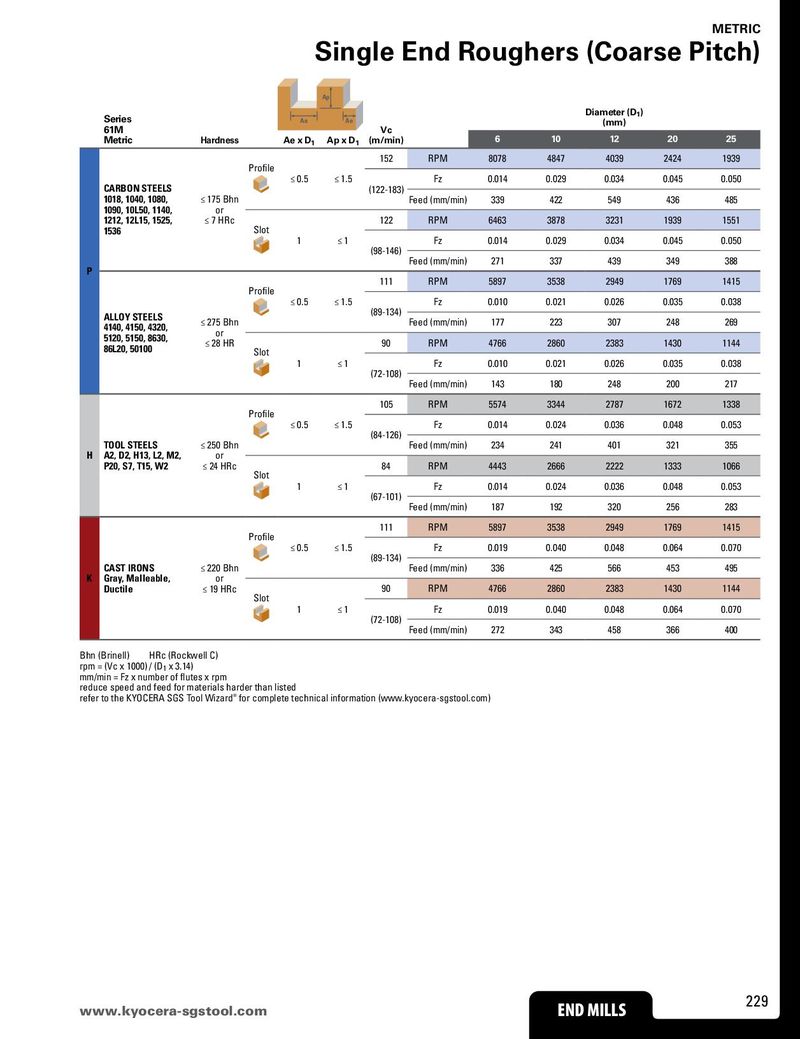

METRIC Single End Roughers (Coarse Pitch) Ap Series Diameter (D1) Ae Ae (mm) 61M Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 6 10 12 20 25 152 RPM 8078 4847 4039 2424 1939 Profile ≤ 0.5 ≤ 1.5 Fz 0.014 0.029 0.034 0.045 0.050 CARBON STEELS (122-183) 1018, 1040, 1080, ≤ 175 Bhn Feed (mm/min) 339 422 549 436 485 1090, 10L50, 1140, or 1212, 12L15, 1525, ≤ 7 HRc 122 RPM 6463 3878 3231 1939 1551 1536 Slot 1 ≤1 Fz 0.014 0.029 0.034 0.045 0.050 (98-146) Feed (mm/min) 271 337 439 349 388 P 111 RPM 5897 3538 2949 1769 1415 Profile ≤ 0.5 ≤ 1.5 Fz 0.010 0.021 0.026 0.035 0.038 ALLOY STEELS (89-134) 4140, 4150, 4320, ≤ 275 Bhn Feed (mm/min) 177 223 307 248 269 5120, 5150, 8630, or 86L20, 50100 ≤ 28 HR 90 RPM 4766 2860 2383 1430 1144 Slot 1 ≤1 Fz 0.010 0.021 0.026 0.035 0.038 (72-108) Feed (mm/min) 143 180 248 200 217 105 RPM 5574 3344 2787 1672 1338 Profile ≤ 0.5 ≤ 1.5 Fz 0.014 0.024 0.036 0.048 0.053 (84-126) TOOL STEELS ≤ 250 Bhn Feed (mm/min) 234 241 401 321 355 H A2, D2, H13, L2, M2, or P20, S7, T15, W2 ≤ 24 HRc 84 RPM 4443 2666 2222 1333 1066 Slot 1 ≤1 Fz 0.014 0.024 0.036 0.048 0.053 (67-101) Feed (mm/min) 187 192 320 256 283 111 RPM 5897 3538 2949 1769 1415 Profile ≤ 0.5 ≤ 1.5 Fz 0.019 0.040 0.048 0.064 0.070 (89-134) CAST IRONS ≤ 220 Bhn Feed (mm/min) 336 425 566 453 495 K Gray, Malleable, or Ductile ≤ 19 HRc 90 RPM 4766 2860 2383 1430 1144 Slot 1 ≤1 Fz 0.019 0.040 0.048 0.064 0.070 (72-108) Feed (mm/min) 272 343 458 366 400 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x number of flutes x rpm reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 229

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском