Общий каталог SGS 2018 - страница 212

Навигация

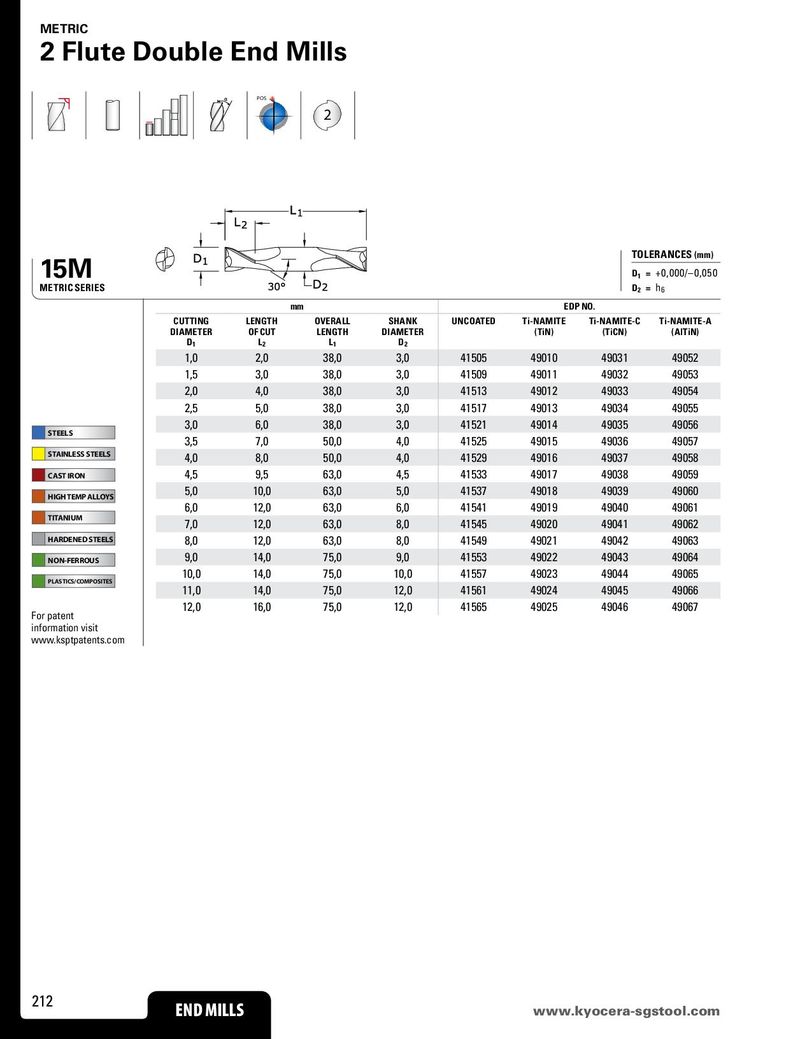

METRIC 2 Flute Double End Mills POS 2 15M TOLERANCES (mm) D1 = +0,000/–0,050 METRIC SERIES D2 = h6 mm EDP NO. CUTTING LENGTH OVERALL SHANK UNCOATED Ti-NAMITE Ti-NAMITE-C Ti-NAMITE-A DIAMETER OF CUT LENGTH DIAMETER (TiN) (TiCN) (AlTiN) D1 L2 L1 D2 1,0 2,0 38,0 3,0 41505 49010 49031 49052 1,5 3,0 38,0 3,0 41509 49011 49032 49053 2,0 4,0 38,0 3,0 41513 49012 49033 49054 2,5 5,0 38,0 3,0 41517 49013 49034 49055 STEELS 3,0 6,0 38,0 3,0 41521 49014 49035 49056 3,5 7,0 50,0 4,0 41525 49015 49036 49057 STAINLESS STEELS 4,0 8,0 50,0 4,0 41529 49016 49037 49058 CAST IRON 4,5 9,5 63,0 4,5 41533 49017 49038 49059 HIGH TEMP ALLOYS 5,0 10,0 63,0 5,0 41537 49018 49039 49060 6,0 12,0 63,0 6,0 41541 49019 49040 49061 TITANIUM 7,0 12,0 63,0 8,0 41545 49020 49041 49062 HARDENED STEELS 8,0 12,0 63,0 8,0 41549 49021 49042 49063 NON-FERROUS 9,0 14,0 75,0 9,0 41553 49022 49043 49064 PLASTICS/COMPOSITES 10,0 14,0 75,0 10,0 41557 49023 49044 49065 11,0 14,0 75,0 12,0 41561 49024 49045 49066 For patent 12,0 16,0 75,0 12,0 41565 49025 49046 49067 information visit www.ksptpatents.com 212 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском