Общий каталог SGS 2018 - страница 206

Навигация

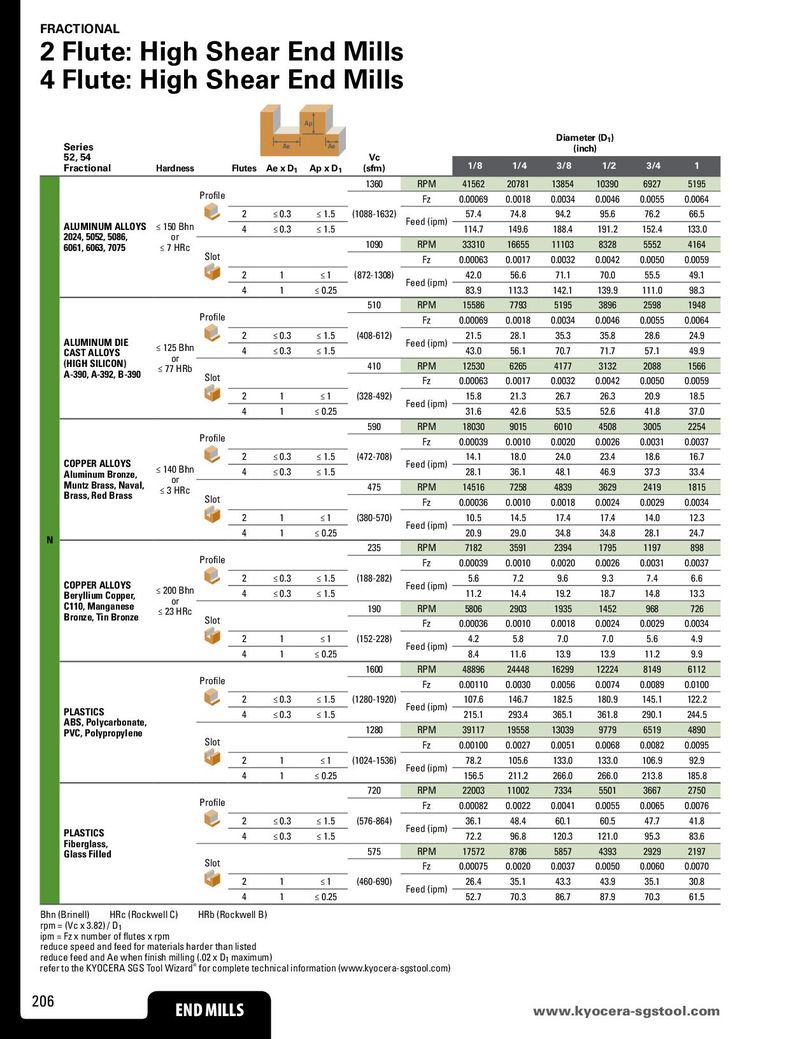

FRACTIONAL 2 Flute: High Shear End Mills 4 Flute: High Shear End Mills Ap Series Diameter (D1) Ae Ae (inch) 52, 54 Vc 1/8 1/4 3/8 1/2 3/4 1 Fractional Hardness Flutes Ae x D1 Ap x D1 (sfm) 1360 RPM 41562 20781 13854 10390 6927 5195 Profile Fz 0.00069 0.0018 0.0034 0.0046 0.0055 0.0064 2 ≤ 0.3 ≤ 1.5 (1088-1632) Feed (ipm) 57.4 74.8 94.2 95.6 76.2 66.5 ALUMINUM ALLOYS ≤ 150 Bhn 4 ≤ 0.3 ≤ 1.5 114.7 149.6 188.4 191.2 152.4 133.0 2024, 5052, 5086, or 1090 RPM 33310 16655 11103 8328 5552 4164 6061, 6063, 7075 ≤ 7 HRc Slot Fz 0.00063 0.0017 0.0032 0.0042 0.0050 0.0059 2 1 ≤1 (872-1308) Feed (ipm) 42.0 56.6 71.1 70.0 55.5 49.1 4 1 ≤ 0.25 83.9 113.3 142.1 139.9 111.0 98.3 510 RPM 15586 7793 5195 3896 2598 1948 Profile Fz 0.00069 0.0018 0.0034 0.0046 0.0055 0.0064 ALUMINUM DIE 2 ≤ 0.3 ≤ 1.5 (408-612) Feed (ipm) 21.5 28.1 35.3 35.8 28.6 24.9 CAST ALLOYS ≤ 125 Bhn 4 ≤ 0.3 ≤ 1.5 43.0 56.1 70.7 71.7 57.1 49.9 (HIGH SILICON) or 410 RPM 12530 6265 4177 3132 2088 1566 A-390, A-392, B-390 ≤ 77 HRb Slot Fz 0.00063 0.0017 0.0032 0.0042 0.0050 0.0059 2 1 ≤1 (328-492) Feed (ipm) 15.8 21.3 26.7 26.3 20.9 18.5 4 1 ≤ 0.25 31.6 42.6 53.5 52.6 41.8 37.0 590 RPM 18030 9015 6010 4508 3005 2254 Profile Fz 0.00039 0.0010 0.0020 0.0026 0.0031 0.0037 COPPER ALLOYS 2 ≤ 0.3 ≤ 1.5 (472-708) Feed (ipm) 14.1 18.0 24.0 23.4 18.6 16.7 Aluminum Bronze, ≤ 140 Bhn 4 ≤ 0.3 ≤ 1.5 28.1 36.1 48.1 46.9 37.3 33.4 Muntz Brass, Naval, or 475 RPM 14516 7258 4839 3629 2419 1815 Brass, Red Brass ≤ 3 HRc Slot Fz 0.00036 0.0010 0.0018 0.0024 0.0029 0.0034 2 1 ≤1 (380-570) Feed (ipm) 10.5 14.5 17.4 17.4 14.0 12.3 N 4 1 ≤ 0.25 20.9 29.0 34.8 34.8 28.1 24.7 235 RPM 7182 3591 2394 1795 1197 898 Profile Fz 0.00039 0.0010 0.0020 0.0026 0.0031 0.0037 COPPER ALLOYS 2 ≤ 0.3 ≤ 1.5 (188-282) Feed (ipm) 5.6 7.2 9.6 9.3 7.4 6.6 Beryllium Copper, ≤ 200 Bhn 4 ≤ 0.3 ≤ 1.5 11.2 14.4 19.2 18.7 14.8 13.3 C110, Manganese or 190 RPM 5806 2903 1935 1452 968 726 Bronze, Tin Bronze ≤ 23 HRc Slot Fz 0.00036 0.0010 0.0018 0.0024 0.0029 0.0034 2 1 ≤1 (152-228) Feed (ipm) 4.2 5.8 7.0 7.0 5.6 4.9 4 1 ≤ 0.25 8.4 11.6 13.9 13.9 11.2 9.9 1600 RPM 48896 24448 16299 12224 8149 6112 Profile Fz 0.00110 0.0030 0.0056 0.0074 0.0089 0.0100 2 ≤ 0.3 ≤ 1.5 (1280-1920) Feed (ipm) 107.6 146.7 182.5 180.9 145.1 122.2 PLASTICS 4 ≤ 0.3 ≤ 1.5 215.1 293.4 365.1 361.8 290.1 244.5 ABS, Polycarbonate, 1280 RPM 39117 19558 13039 9779 6519 4890 PVC, Polypropylene Slot Fz 0.00100 0.0027 0.0051 0.0068 0.0082 0.0095 2 1 ≤1 (1024-1536) Feed (ipm) 78.2 105.6 133.0 133.0 106.9 92.9 4 1 ≤ 0.25 156.5 211.2 266.0 266.0 213.8 185.8 720 RPM 22003 11002 7334 5501 3667 2750 Profile Fz 0.00082 0.0022 0.0041 0.0055 0.0065 0.0076 2 ≤ 0.3 ≤ 1.5 (576-864) Feed (ipm) 36.1 48.4 60.1 60.5 47.7 41.8 PLASTICS 4 ≤ 0.3 ≤ 1.5 72.2 96.8 120.3 121.0 95.3 83.6 Fiberglass, 575 RPM 17572 8786 5857 4393 2929 2197 Glass Filled Slot Fz 0.00075 0.0020 0.0037 0.0050 0.0060 0.0070 2 1 ≤1 (460-690) Feed (ipm) 26.4 35.1 43.3 43.9 35.1 30.8 4 1 ≤ 0.25 52.7 70.3 86.7 87.9 70.3 61.5 Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) rpm = (Vc x 3.82) / D1 ipm = Fz x number of flutes x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x D1 maximum) refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) 206 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском