Общий каталог SGS 2018 - страница 199

Навигация

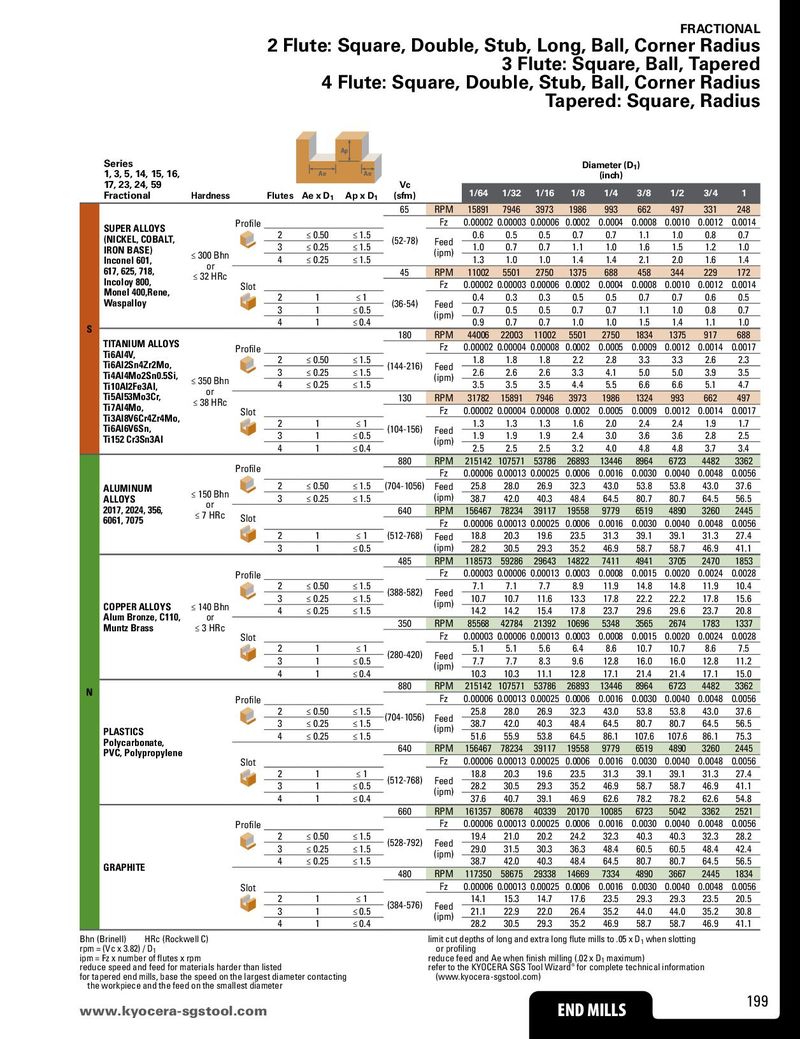

FRACTIONAL 2 Flute: Square, Double, Stub, Long, Ball, Corner Radius 3 Flute: Square, Ball, Tapered 4 Flute: Square, Double, Stub, Ball, Corner Radius Tapered: Square, Radius Ap Series Diameter (D1) 1, 3, 5, 14, 15, 16, Ae Ae (inch) 17, 23, 24, 59 Vc 1/64 1/32 1/16 1/8 1/4 3/8 1/2 3/4 1 Fractional Hardness Flutes Ae x D1 Ap x D1 (sfm) 65 RPM 15891 7946 3973 1986 993 662 497 331 248 SUPER ALLOYS Profile Fz 0.00002 0.00003 0.00006 0.0002 0.0004 0.0008 0.0010 0.0012 0.0014 (NICKEL, COBALT, 2 ≤ 0.50 ≤ 1.5 (52-78) Feed 0.6 0.5 0.5 0.7 0.7 1.1 1.0 0.8 0.7 IRON BASE) ≤ 300 Bhn 3 ≤ 0.25 ≤ 1.5 (ipm) 1.0 0.7 0.7 1.1 1.0 1.6 1.5 1.2 1.0 Inconel 601, or 4 ≤ 0.25 ≤ 1.5 1.3 1.0 1.0 1.4 1.4 2.1 2.0 1.6 1.4 617, 625, 718, ≤ 32 HRc 45 RPM 11002 5501 2750 1375 688 458 344 229 172 Incoloy 800, Slot Fz 0.00002 0.00003 0.00006 0.0002 0.0004 0.0008 0.0010 0.0012 0.0014 Monel 400,Rene, 2 1 ≤1 0.4 0.3 0.3 0.5 0.5 0.7 0.7 0.6 0.5 Waspalloy 3 1 ≤ 0.5 (36-54) Feed 0.7 0.5 0.5 0.7 0.7 1.1 1.0 0.8 0.7 4 1 ≤ 0.4 (ipm) 0.9 0.7 0.7 1.0 1.0 1.5 1.4 1.1 1.0 S 180 RPM 44006 22003 11002 5501 2750 1834 1375 917 688 TITANIUM ALLOYS Profile Fz 0.00002 0.00004 0.00008 0.0002 0.0005 0.0009 0.0012 0.0014 0.0017 Ti6Al4V, 2 ≤ 0.50 ≤ 1.5 1.8 1.8 1.8 2.2 2.8 3.3 3.3 2.6 2.3 Ti6Al2Sn4Zr2Mo, 3 ≤ 0.25 ≤ 1.5 (144-216) Feed 2.6 2.6 2.6 3.3 4.1 5.0 5.0 3.9 3.5 Ti4Al4Mo2Sn0.5Si, ≤ 350 Bhn (ipm) Ti10Al2Fe3Al, or 4 ≤ 0.25 ≤ 1.5 3.5 3.5 3.5 4.4 5.5 6.6 6.6 5.1 4.7 Ti5Al53Mo3Cr, ≤ 38 HRc 130 RPM 31782 15891 7946 3973 1986 1324 993 662 497 Ti7Al4Mo, Slot Fz 0.00002 0.00004 0.00008 0.0002 0.0005 0.0009 0.0012 0.0014 0.0017 Ti3Al8V6Cr4Zr4Mo, 2 1 ≤1 1.3 1.3 1.3 1.6 2.0 2.4 2.4 1.9 1.7 Ti6Al6V6Sn, 3 1 ≤ 0.5 (104-156) Feed 1.9 1.9 1.9 2.4 3.0 3.6 3.6 2.8 2.5 Ti152 Cr3Sn3Al 4 1 ≤ 0.4 (ipm) 2.5 2.5 2.5 3.2 4.0 4.8 4.8 3.7 3.4 Profile 880 RPM 215142 107571 53786 26893 13446 8964 6723 4482 3362 Fz 0.00006 0.00013 0.00025 0.0006 0.0016 0.0030 0.0040 0.0048 0.0056 ALUMINUM ≤ 150 Bhn 2 ≤ 0.50 ≤ 1.5 (704-1056) Feed 25.8 28.0 26.9 32.3 43.0 53.8 53.8 43.0 37.6 ALLOYS or 3 ≤ 0.25 ≤ 1.5 (ipm) 38.7 42.0 40.3 48.4 64.5 80.7 80.7 64.5 56.5 2017, 2024, 356, ≤ 7 HRc Slot 640 RPM 156467 78234 39117 19558 9779 6519 4890 3260 2445 6061, 7075 Fz 0.00006 0.00013 0.00025 0.0006 0.0016 0.0030 0.0040 0.0048 0.0056 2 1 ≤1 (512-768) Feed 18.8 20.3 19.6 23.5 31.3 39.1 39.1 31.3 27.4 3 1 ≤ 0.5 (ipm) 28.2 30.5 29.3 35.2 46.9 58.7 58.7 46.9 41.1 485 RPM 118573 59286 29643 14822 7411 4941 3705 2470 1853 Profile Fz 0.00003 0.00006 0.00013 0.0003 0.0008 0.0015 0.0020 0.0024 0.0028 2 ≤ 0.50 ≤ 1.5 (388-582) Feed 7.1 7.1 7.7 8.9 11.9 14.8 14.8 11.9 10.4 COPPER ALLOYS ≤ 140 Bhn 3 ≤ 0.25 ≤ 1.5 (ipm) 10.7 10.7 11.6 13.3 17.8 22.2 22.2 17.8 15.6 Alum Bronze, C110, or 4 ≤ 0.25 ≤ 1.5 14.2 14.2 15.4 17.8 23.7 29.6 29.6 23.7 20.8 Muntz Brass ≤ 3 HRc 350 RPM 85568 42784 21392 10696 5348 3565 2674 1783 1337 Slot Fz 0.00003 0.00006 0.00013 0.0003 0.0008 0.0015 0.0020 0.0024 0.0028 2 1 ≤1 (280-420) Feed 5.1 5.1 5.6 6.4 8.6 10.7 10.7 8.6 7.5 3 1 ≤ 0.5 (ipm) 7.7 7.7 8.3 9.6 12.8 16.0 16.0 12.8 11.2 4 1 ≤ 0.4 10.3 10.3 11.1 12.8 17.1 21.4 21.4 17.1 15.0 N 880 RPM 215142 107571 53786 26893 13446 8964 6723 4482 3362 Profile Fz 0.00006 0.00013 0.00025 0.0006 0.0016 0.0030 0.0040 0.0048 0.0056 2 ≤ 0.50 ≤ 1.5 (704-1056) Feed 25.8 28.0 26.9 32.3 43.0 53.8 53.8 43.0 37.6 PLASTICS 3 ≤ 0.25 ≤ 1.5 (ipm) 38.7 42.0 40.3 48.4 64.5 80.7 80.7 64.5 56.5 Polycarbonate, 4 ≤ 0.25 ≤ 1.5 51.6 55.9 53.8 64.5 86.1 107.6 107.6 86.1 75.3 PVC, Polypropylene 640 RPM 156467 78234 39117 19558 9779 6519 4890 3260 2445 Slot Fz 0.00006 0.00013 0.00025 0.0006 0.0016 0.0030 0.0040 0.0048 0.0056 2 1 ≤1 (512-768) Feed 18.8 20.3 19.6 23.5 31.3 39.1 39.1 31.3 27.4 3 1 ≤ 0.5 (ipm) 28.2 30.5 29.3 35.2 46.9 58.7 58.7 46.9 41.1 4 1 ≤ 0.4 37.6 40.7 39.1 46.9 62.6 78.2 78.2 62.6 54.8 660 RPM 161357 80678 40339 20170 10085 6723 5042 3362 2521 Profile Fz 0.00006 0.00013 0.00025 0.0006 0.0016 0.0030 0.0040 0.0048 0.0056 2 ≤ 0.50 ≤ 1.5 (528-792) Feed 19.4 21.0 20.2 24.2 32.3 40.3 40.3 32.3 28.2 3 ≤ 0.25 ≤ 1.5 (ipm) 29.0 31.5 30.3 36.3 48.4 60.5 60.5 48.4 42.4 GRAPHITE 4 ≤ 0.25 ≤ 1.5 38.7 42.0 40.3 48.4 64.5 80.7 80.7 64.5 56.5 480 RPM 117350 58675 29338 14669 7334 4890 3667 2445 1834 Slot Fz 0.00006 0.00013 0.00025 0.0006 0.0016 0.0030 0.0040 0.0048 0.0056 2 1 ≤1 (384-576) Feed 14.1 15.3 14.7 17.6 23.5 29.3 29.3 23.5 20.5 3 1 ≤ 0.5 (ipm) 21.1 22.9 22.0 26.4 35.2 44.0 44.0 35.2 30.8 4 1 ≤ 0.4 28.2 30.5 29.3 35.2 46.9 58.7 58.7 46.9 41.1 Bhn (Brinell) HRc (Rockwell C) limit cut depths of long and extra long flute mills to .05 x D1 when slotting rpm = (Vc x 3.82) / D1 or profiling ipm = Fz x number of flutes x rpm reduce feed and Ae when finish milling (.02 x D1 maximum) reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information for tapered end mills, base the speed on the largest diameter contacting (www.kyocera-sgstool.com) the workpiece and the feed on the smallest diameter www.kyocerEaN-DsgMstILoLoSl.com END MILLS 199

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском