Общий каталог SGS 2018 - страница 137

Навигация

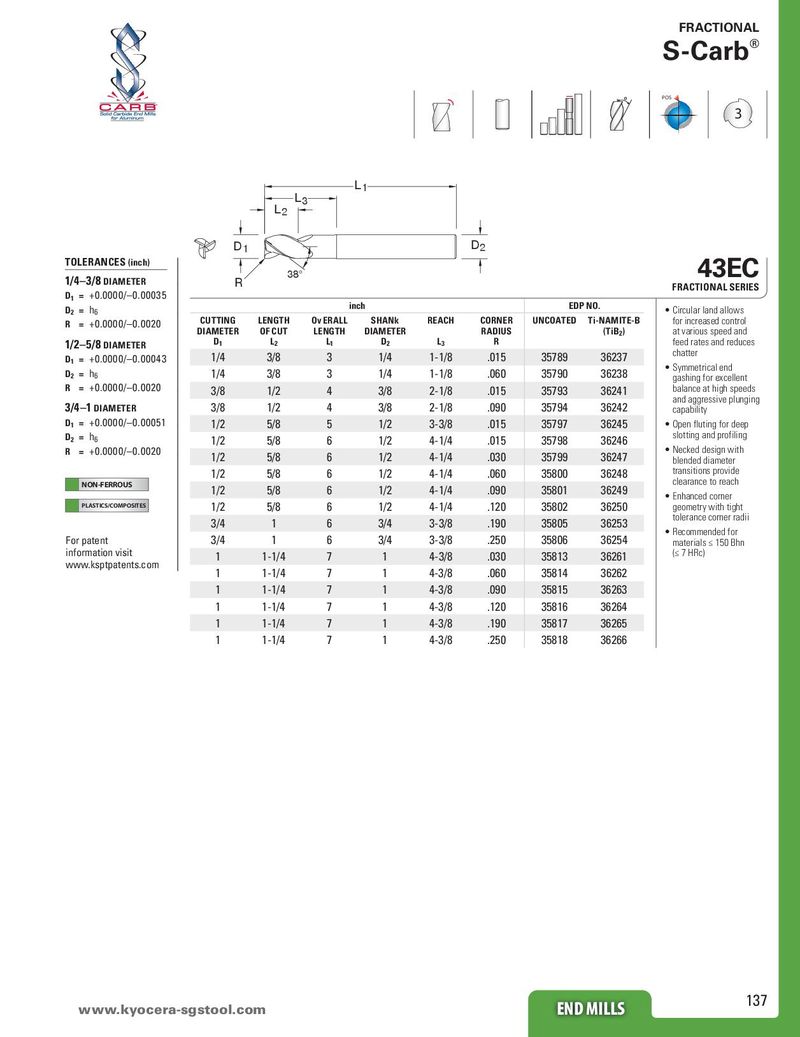

FRACTIONAL S-Carb® POS ® 3 L3 L1 L2 D1 D2 TOLERANCES (inch) 43EC 1/4–3/8 DIAMETER R 38° +0.0000/–0.00035 Fractional Series D1 = D2 = h6 inch EDP No. • Circular land allows R = +0.0000/–0.0020 Cutting Length Ov erall Shank Reach Corner Uncoated Ti-NAMITE-B for increased control Diameter of Cut Length Diameter Radius (TiB2) at various speed and 1/2–5/8 DIAMETER D1 l2 L1 D2 L3 R feed rates and reduces D1 = +0.0000/–0.00043 1/4 3/8 3 1/4 1-1/8 .015 35789 36237 chatter D2 = h6 1/4 3/8 3 1/4 1-1/8 .060 35790 36238 • Symmetrical end gashing for excellent R = +0.0000/–0.0020 3/8 1/2 4 3/8 2-1/8 .015 35793 36241 balance at high speeds 3/4–1 DIAMETER 3/8 1/2 4 3/8 2-1/8 .090 35794 36242 and aggressive plunging capability D1 = +0.0000/–0.00051 1/2 5/8 5 1/2 3-3/8 .015 35797 36245 • Open fluting for deep D2 = h6 1/2 5/8 6 1/2 4-1/4 .015 35798 36246 slotting and profiling R = +0.0000/–0.0020 1/2 5/8 6 1/2 4-1/4 .030 35799 36247 • Necked design with blended diameter 1/2 5/8 6 1/2 4-1/4 .060 35800 36248 transitions provide NON-FERROUS 1/2 5/8 6 1/2 4-1/4 .090 35801 36249 clearance to reach • Enhanced corner PLASTICS/COMPOSITES 1/2 5/8 6 1/2 4-1/4 .120 35802 36250 geometry with tight 3/4 1 6 3/4 3-3/8 .190 35805 36253 tolerance corner radii For patent 3/4 1 6 3/4 3-3/8 .250 35806 36254 • Recommended for materials ≤ 150 Bhn information visit 1 1-1/4 7 1 4-3/8 .030 35813 36261 (≤ 7 HRc) www.ksptpatents.com 1 1-1/4 7 1 4-3/8 .060 35814 36262 1 1-1/4 7 1 4-3/8 .090 35815 36263 1 1-1/4 7 1 4-3/8 .120 35816 36264 1 1-1/4 7 1 4-3/8 .190 35817 36265 1 1-1/4 7 1 4-3/8 .250 35818 36266 www.kyocerEaN-DsgMstILoLoSl.com END MILLS 137

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском