Общий каталог SGS 2018 - страница 127

Навигация

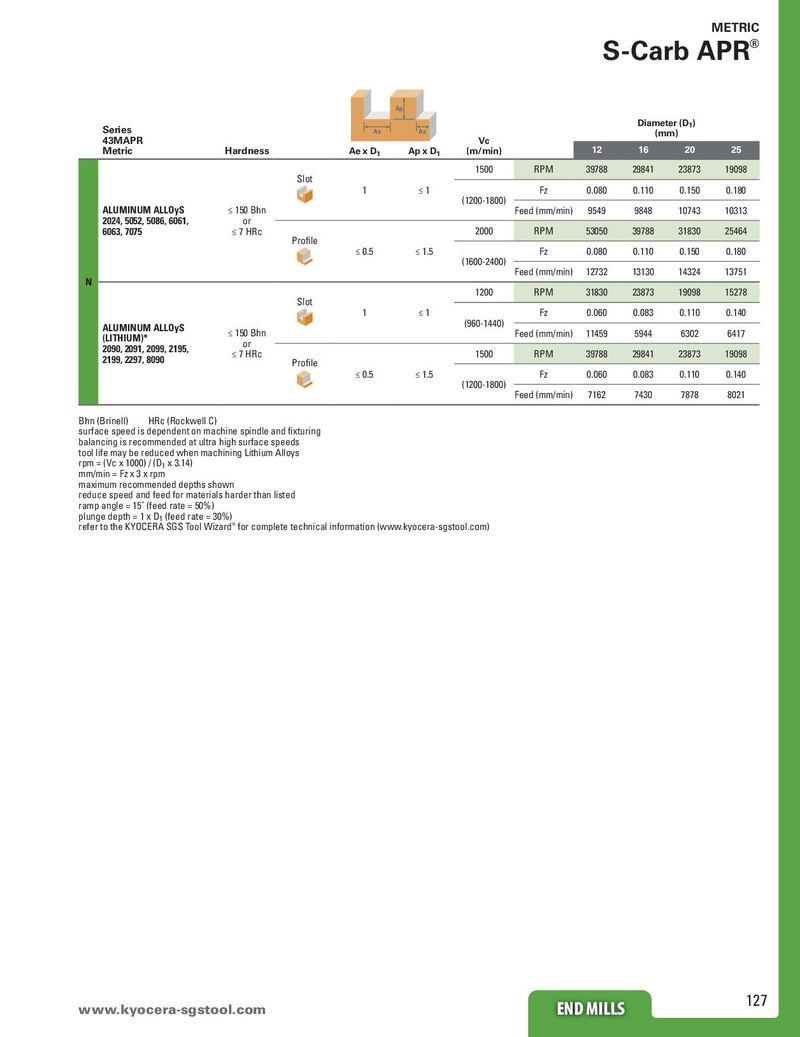

METRIC S-Carb APR® Ap Series Diameter (D1) Ae Ae (mm) 43MAPR Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 12 16 20 25 1500 RPM 39788 29841 23873 19098 Slot 1 ≤1 Fz 0.080 0.110 0.150 0.180 (1200-1800) Aluminum AlloyS ≤ 150 Bhn Feed (mm/min) 9549 9848 10743 10313 2024, 5052, 5086, 6061, or 6063, 7075 ≤ 7 HRc 2000 RPM 53050 39788 31830 25464 Profile ≤ 0.5 ≤ 1.5 Fz 0.080 0.110 0.150 0.180 (1600-2400) Feed (mm/min) 12732 13130 14324 13751 N 1200 RPM 31830 23873 19098 15278 Slot 1 ≤1 Fz 0.060 0.083 0.110 0.140 Aluminum AlloyS (960-1440) (LITHIUM)* ≤ 150 Bhn Feed (mm/min) 11459 5944 6302 6417 2090, 2091, 2099, 2195, or 2199, 2297, 8090 ≤ 7 HRc 1500 RPM 39788 29841 23873 19098 Profile ≤ 0.5 ≤ 1.5 Fz 0.060 0.083 0.110 0.140 (1200-1800) Feed (mm/min) 7162 7430 7878 8021 Bhn (Brinell) HRc (Rockwell C) surface speed is dependent on machine spindle and fixturing balancing is recommended at ultra high surface speeds tool life may be reduced when machining Lithium Alloys rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x 3 x rpm maximum recommended depths shown reduce speed and feed for materials harder than listed ramp angle = 15˚ (feed rate = 50%) plunge depth = 1 x D1 (feed rate = 30%) refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 127

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском