Общий каталог SGS 2018 - страница 115

Навигация

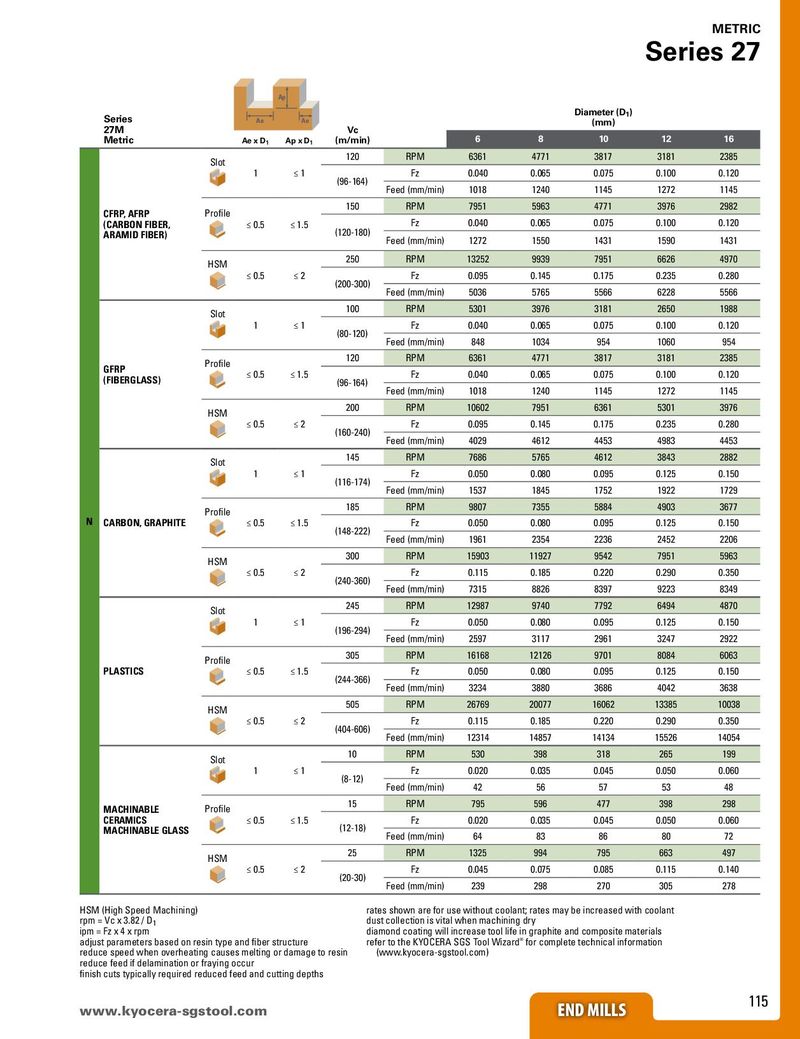

METRIC Series 27 Ap Series Diameter (D1) Ae Ae (mm) 27M Vc Metric Ae x D1 Ap x D1 (m/min) 6 8 10 12 16 Slot 120 RPM 6361 4771 3817 3181 2385 1 ≤1 (96-164) Fz 0.040 0.065 0.075 0.100 0.120 Feed (mm/min) 1018 1240 1145 1272 1145 CFRP, AFRP Profile 150 RPM 7951 5963 4771 3976 2982 (CARBON FIBER, ≤ 0.5 ≤ 1.5 Fz 0.040 0.065 0.075 0.100 0.120 ARAMID FIBER) (120-180) Feed (mm/min) 1272 1550 1431 1590 1431 HSM 250 RPM 13252 9939 7951 6626 4970 ≤ 0.5 ≤2 (200-300) Fz 0.095 0.145 0.175 0.235 0.280 Feed (mm/min) 5036 5765 5566 6228 5566 Slot 100 RPM 5301 3976 3181 2650 1988 1 ≤1 (80-120) Fz 0.040 0.065 0.075 0.100 0.120 Feed (mm/min) 848 1034 954 1060 954 Profile 120 RPM 6361 4771 3817 3181 2385 GFRP ≤ 0.5 ≤ 1.5 Fz 0.040 0.065 0.075 0.100 0.120 (FIBERGLASS) (96-164) Feed (mm/min) 1018 1240 1145 1272 1145 HSM 200 RPM 10602 7951 6361 5301 3976 ≤ 0.5 ≤2 (160-240) Fz 0.095 0.145 0.175 0.235 0.280 Feed (mm/min) 4029 4612 4453 4983 4453 Slot 145 RPM 7686 5765 4612 3843 2882 1 ≤1 (116-174) Fz 0.050 0.080 0.095 0.125 0.150 Feed (mm/min) 1537 1845 1752 1922 1729 Profile 185 RPM 9807 7355 5884 4903 3677 N CARBON, GRAPHITE ≤ 0.5 ≤ 1.5 Fz 0.050 0.080 0.095 0.125 0.150 (148-222) Feed (mm/min) 1961 2354 2236 2452 2206 HSM 300 RPM 15903 11927 9542 7951 5963 ≤ 0.5 ≤2 (240-360) Fz 0.115 0.185 0.220 0.290 0.350 Feed (mm/min) 7315 8826 8397 9223 8349 Slot 245 RPM 12987 9740 7792 6494 4870 1 ≤1 (196-294) Fz 0.050 0.080 0.095 0.125 0.150 Feed (mm/min) 2597 3117 2961 3247 2922 Profile 305 RPM 16168 12126 9701 8084 6063 PLASTICS ≤ 0.5 ≤ 1.5 (244-366) Fz 0.050 0.080 0.095 0.125 0.150 Feed (mm/min) 3234 3880 3686 4042 3638 HSM 505 RPM 26769 20077 16062 13385 10038 ≤ 0.5 ≤2 (404-606) Fz 0.115 0.185 0.220 0.290 0.350 Feed (mm/min) 12314 14857 14134 15526 14054 Slot 10 RPM 530 398 318 265 199 1 ≤1 (8-12) Fz 0.020 0.035 0.045 0.050 0.060 Feed (mm/min) 42 56 57 53 48 MACHINABLE Profile 15 RPM 795 596 477 398 298 CERAMICS ≤ 0.5 ≤ 1.5 (12-18) Fz 0.020 0.035 0.045 0.050 0.060 MACHINABLE GLASS Feed (mm/min) 64 83 86 80 72 HSM 25 RPM 1325 994 795 663 497 ≤ 0.5 ≤2 (20-30) Fz 0.045 0.075 0.085 0.115 0.140 Feed (mm/min) 239 298 270 305 278 HSM (High Speed Machining) rates shown are for use without coolant; rates may be increased with coolant rpm = Vc x 3.82 / D1 dust collection is vital when machining dry ipm = Fz x 4 x rpm diamond coating will increase tool life in graphite and composite materials adjust parameters based on resin type and fiber structure refer to the KYOCERA SGS Tool Wizard® for complete technical information reduce speed when overheating causes melting or damage to resin (www.kyocera-sgstool.com) reduce feed if delamination or fraying occur finish cuts typically required reduced feed and cutting depths www.kyocerEaN-DsgMstILoLoSl.com END MILLS 115

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском