Общий каталог SGS 2018 - страница 113

Навигация

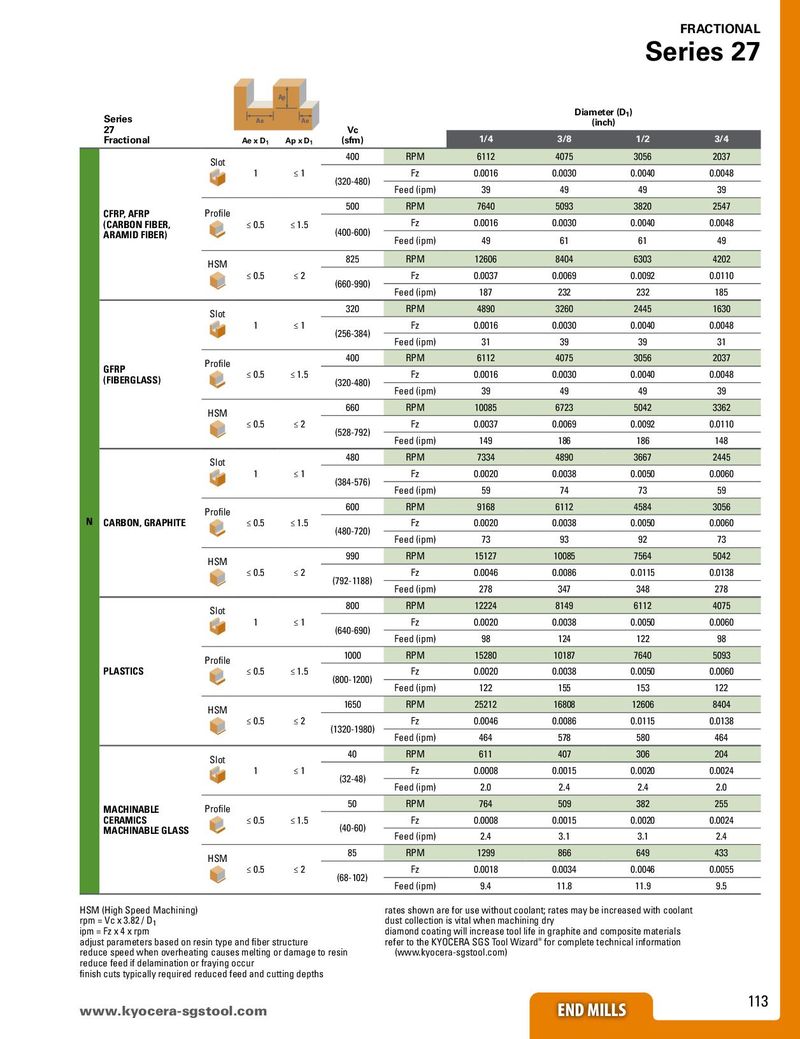

FRACTIONAL Series 27 Ap Series Diameter (D1) Ae Ae (inch) 27 Vc Fractional Ae x D1 Ap x D1 (sfm) 1/4 3/8 1/2 3/4 Slot 400 RPM 6112 4075 3056 2037 1 ≤1 (320-480) Fz 0.0016 0.0030 0.0040 0.0048 Feed (ipm) 39 49 49 39 CFRP, AFRP Profile 500 RPM 7640 5093 3820 2547 (CARBON FIBER, ≤ 0.5 ≤ 1.5 Fz 0.0016 0.0030 0.0040 0.0048 ARAMID FIBER) (400-600) Feed (ipm) 49 61 61 49 HSM 825 RPM 12606 8404 6303 4202 ≤ 0.5 ≤2 (660-990) Fz 0.0037 0.0069 0.0092 0.0110 Feed (ipm) 187 232 232 185 Slot 320 RPM 4890 3260 2445 1630 1 ≤1 (256-384) Fz 0.0016 0.0030 0.0040 0.0048 Feed (ipm) 31 39 39 31 Profile 400 RPM 6112 4075 3056 2037 GFRP ≤ 0.5 ≤ 1.5 Fz 0.0016 0.0030 0.0040 0.0048 (FIBERGLASS) (320-480) Feed (ipm) 39 49 49 39 HSM 660 RPM 10085 6723 5042 3362 ≤ 0.5 ≤2 (528-792) Fz 0.0037 0.0069 0.0092 0.0110 Feed (ipm) 149 186 186 148 Slot 480 RPM 7334 4890 3667 2445 1 ≤1 (384-576) Fz 0.0020 0.0038 0.0050 0.0060 Feed (ipm) 59 74 73 59 Profile 600 RPM 9168 6112 4584 3056 N CARBON, GRAPHITE ≤ 0.5 ≤ 1.5 Fz 0.0020 0.0038 0.0050 0.0060 (480-720) Feed (ipm) 73 93 92 73 HSM 990 RPM 15127 10085 7564 5042 ≤ 0.5 ≤2 (792-1188) Fz 0.0046 0.0086 0.0115 0.0138 Feed (ipm) 278 347 348 278 Slot 800 RPM 12224 8149 6112 4075 1 ≤1 (640-690) Fz 0.0020 0.0038 0.0050 0.0060 Feed (ipm) 98 124 122 98 Profile 1000 RPM 15280 10187 7640 5093 PLASTICS ≤ 0.5 ≤ 1.5 (800-1200) Fz 0.0020 0.0038 0.0050 0.0060 Feed (ipm) 122 155 153 122 HSM 1650 RPM 25212 16808 12606 8404 ≤ 0.5 ≤2 (1320-1980) Fz 0.0046 0.0086 0.0115 0.0138 Feed (ipm) 464 578 580 464 Slot 40 RPM 611 407 306 204 1 ≤1 (32-48) Fz 0.0008 0.0015 0.0020 0.0024 Feed (ipm) 2.0 2.4 2.4 2.0 MACHINABLE Profile 50 RPM 764 509 382 255 CERAMICS ≤ 0.5 ≤ 1.5 (40-60) Fz 0.0008 0.0015 0.0020 0.0024 MACHINABLE GLASS Feed (ipm) 2.4 3.1 3.1 2.4 HSM 85 RPM 1299 866 649 433 ≤ 0.5 ≤2 (68-102) Fz 0.0018 0.0034 0.0046 0.0055 Feed (ipm) 9.4 11.8 11.9 9.5 HSM (High Speed Machining) rates shown are for use without coolant; rates may be increased with coolant rpm = Vc x 3.82 / D1 dust collection is vital when machining dry ipm = Fz x 4 x rpm diamond coating will increase tool life in graphite and composite materials adjust parameters based on resin type and fiber structure refer to the KYOCERA SGS Tool Wizard® for complete technical information reduce speed when overheating causes melting or damage to resin (www.kyocera-sgstool.com) reduce feed if delamination or fraying occur finish cuts typically required reduced feed and cutting depths www.kyocerEaN-DsgMstILoLoSl.com END MILLS 113

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском