Общий каталог SGS 2018 - страница 103

Навигация

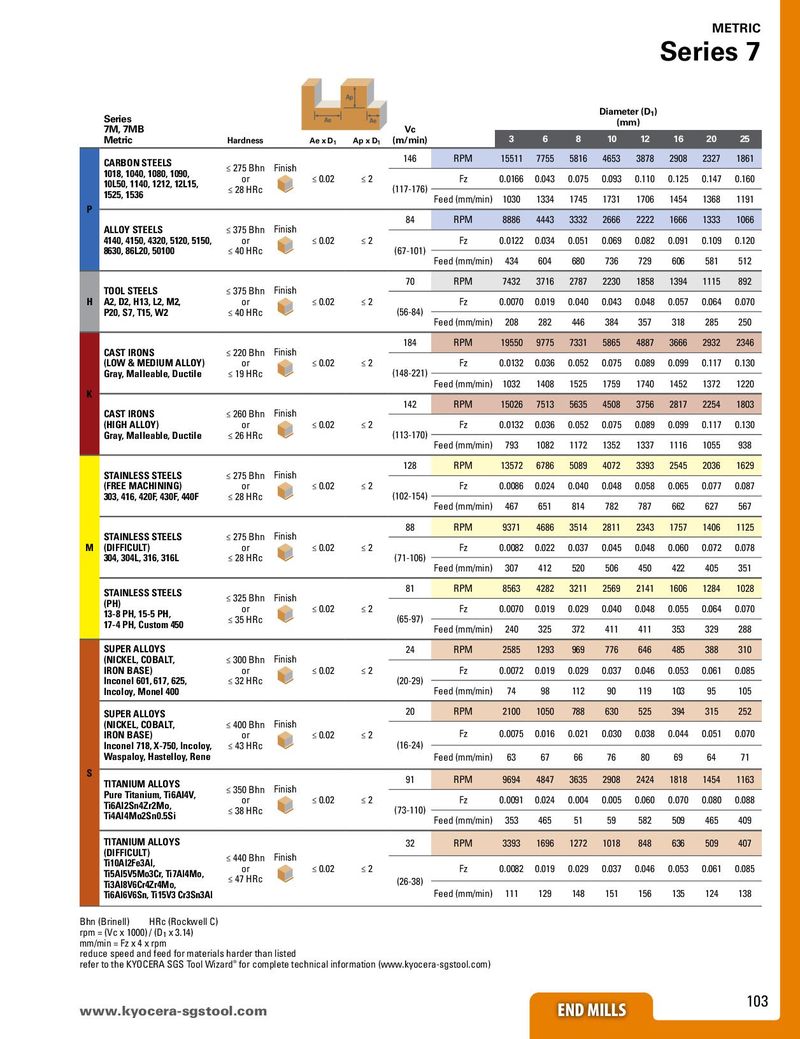

METRIC Series 7 Ap Series Diameter (D1) Ae Ae (mm) 7M, 7MB Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 3 6 8 10 12 16 20 25 CARBON STEELS 146 RPM 15511 7755 5816 4653 3878 2908 2327 1861 1018, 1040, 1080, 1090, ≤ 275 Bhn Finish 10L50, 1140, 1212, 12L15, or ≤ 0.02 ≤2 Fz 0.0166 0.043 0.075 0.093 0.110 0.125 0.147 0.160 1525, 1536 ≤ 28 HRc (117-176) Feed (mm/min) 1030 1334 1745 1731 1706 1454 1368 1191 P 84 RPM 8886 4443 3332 2666 2222 1666 1333 1066 ALLOY STEELS ≤ 375 Bhn Finish 4140, 4150, 4320, 5120, 5150, or ≤ 0.02 ≤2 Fz 0.0122 0.034 0.051 0.069 0.082 0.091 0.109 0.120 8630, 86L20, 50100 ≤ 40 HRc (67-101) Feed (mm/min) 434 604 680 736 729 606 581 512 70 RPM 7432 3716 2787 2230 1858 1394 1115 892 TOOL STEELS ≤ 375 Bhn Finish H A2, D2, H13, L2, M2, or ≤ 0.02 ≤2 Fz 0.0070 0.019 0.040 0.043 0.048 0.057 0.064 0.070 P20, S7, T15, W2 ≤ 40 HRc (56-84) Feed (mm/min) 208 282 446 384 357 318 285 250 184 RPM 19550 9775 7331 5865 4887 3666 2932 2346 CAST IRONS ≤ 220 Bhn Finish (LOW & MEDIUM ALLOY) or ≤ 0.02 ≤2 Fz 0.0132 0.036 0.052 0.075 0.089 0.099 0.117 0.130 Gray, Malleable, Ductile ≤ 19 HRc (148-221) Feed (mm/min) 1032 1408 1525 1759 1740 1452 1372 1220 K 142 RPM 15026 7513 5635 4508 3756 2817 2254 1803 CAST IRONS ≤ 260 Bhn Finish (HIGH ALLOY) or ≤ 0.02 ≤2 Fz 0.0132 0.036 0.052 0.075 0.089 0.099 0.117 0.130 Gray, Malleable, Ductile ≤ 26 HRc (113-170) Feed (mm/min) 793 1082 1172 1352 1337 1116 1055 938 128 RPM 13572 6786 5089 4072 3393 2545 2036 1629 STAINLESS STEELS ≤ 275 Bhn Finish (FREE MACHINING) or ≤ 0.02 ≤2 Fz 0.0086 0.024 0.040 0.048 0.058 0.065 0.077 0.087 303, 416, 420F, 430F, 440F ≤ 28 HRc (102-154) Feed (mm/min) 467 651 814 782 787 662 627 567 88 RPM 9371 4686 3514 2811 2343 1757 1406 1125 STAINLESS STEELS ≤ 275 Bhn Finish M (DIFFICULT) or ≤ 0.02 ≤2 Fz 0.0082 0.022 0.037 0.045 0.048 0.060 0.072 0.078 304, 304L, 316, 316L ≤ 28 HRc (71-106) Feed (mm/min) 307 412 520 506 450 422 405 351 STAINLESS STEELS 81 RPM 8563 4282 3211 2569 2141 1606 1284 1028 (PH) ≤ 325 Bhn Finish 13-8 PH, 15-5 PH, or ≤ 0.02 ≤2 Fz 0.0070 0.019 0.029 0.040 0.048 0.055 0.064 0.070 17-4 PH, Custom 450 ≤ 35 HRc (65-97) Feed (mm/min) 240 325 372 411 411 353 329 288 SUPER ALLOYS 24 RPM 2585 1293 969 776 646 485 388 310 (NICKEL, COBALT, ≤ 300 Bhn Finish IRON BASE) or ≤ 0.02 ≤2 Fz 0.0072 0.019 0.029 0.037 0.046 0.053 0.061 0.085 Inconel 601, 617, 625, ≤ 32 HRc (20-29) Incoloy, Monel 400 Feed (mm/min) 74 98 112 90 119 103 95 105 SUPER ALLOYS 20 RPM 2100 1050 788 630 525 394 315 252 (NICKEL, COBALT, ≤ 400 Bhn Finish IRON BASE) or ≤ 0.02 ≤2 Fz 0.0075 0.016 0.021 0.030 0.038 0.044 0.051 0.070 Inconel 718, X-750, Incoloy, ≤ 43 HRc (16-24) Waspaloy, Hastelloy, Rene Feed (mm/min) 63 67 66 76 80 69 64 71 S 91 RPM 9694 4847 3635 2908 2424 1818 1454 1163 TITANIUM ALLOYS ≤ 350 Bhn Finish Pure Titanium, Ti6Al4V, or ≤ 0.02 ≤2 Fz 0.0091 0.024 0.004 0.005 0.060 0.070 0.080 0.088 Ti6Al2Sn4Zr2Mo, ≤ 38 HRc (73-110) Ti4Al4Mo2Sn0.5Si Feed (mm/min) 353 465 51 59 582 509 465 409 TITANIUM ALLOYS 32 RPM 3393 1696 1272 1018 848 636 509 407 (DIFFICULT) ≤ 440 Bhn Finish Ti10Al2Fe3Al, or ≤ 0.02 ≤2 Fz 0.0082 0.019 0.029 0.037 0.046 0.053 0.061 0.085 Ti5Al5V5Mo3Cr, Ti7Al4Mo, ≤ 47 HRc (26-38) Ti3Al8V6Cr4Zr4Mo, Ti6Al6V6Sn, Ti15V3 Cr3Sn3Al Feed (mm/min) 111 129 148 151 156 135 124 138 Bhn (Brinell) HRc (Rockwell C) rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x 4 x rpm reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 10 3

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском