Каталог SGS фрезы с переменным углом спирали Z-carb - страница 4

Навигация

Каталог SGS инструмент для сверления

Каталог SGS инструмент для сверления Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb

Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия

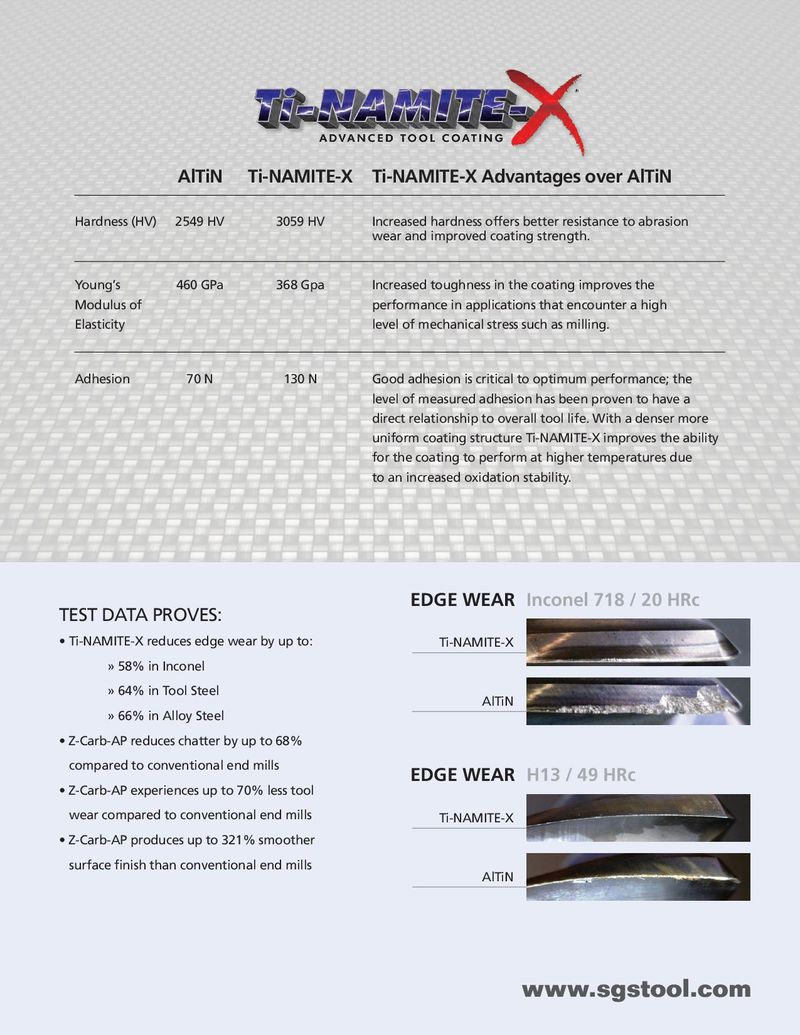

AlTiN Ti-NAMITE-X Ti-NAMITE-X Advantages over AlTiN Hardness (HV) 2549 HV 3059 HV Increased hardness offers better resistance to abrasion wear and improved coating strength. Young’s 460 GPa 368 Gpa Increased toughness in the coating improves the Modulus of performance in applications that encounter a high Elasticity level of mechanical stress such as milling. Adhesion 70 N 130 N Good adhesion is critical to optimum performance; the level of measured adhesion has been proven to have a direct relationship to overall tool life. With a denser more uniform coating structure Ti-NAMITE-X improves the ability for the coating to perform at higher temperatures due to an increased oxidation stability. TEST DATA PROVES: EDGE WEAR Inconel 718 / 20 HRc • Ti-NAMITE-X reduces edge wear by up to: Ti-NAMITE-X » 58% in Inconel » 64% in Tool Steel AlTiN » 66% in Alloy Steel • Z-Carb-AP reduces chatter by up to 68% compared to conventional end mills EDGE WEAR H13 / 49 HRc • Z-Carb-AP experiences up to 70% less tool wear compared to conventional end mills Ti-NAMITE-X • Z-Carb-AP produces up to 321% smoother surface finish than conventional end mills AlTiN