Каталог SGS фрезы с переменным углом спирали Z-carb - страница 13

Навигация

Каталог SGS инструмент для сверления

Каталог SGS инструмент для сверления Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb

Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия

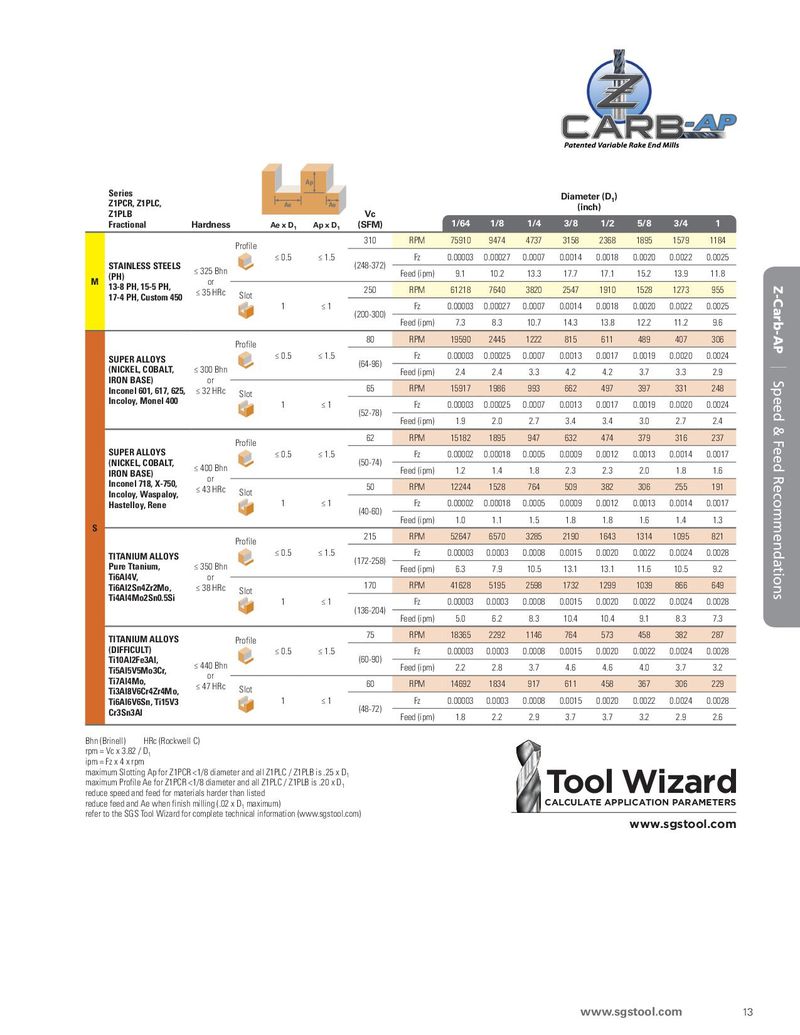

Ap Series Diameter (D1) Z1PCR, Z1PLC, Ae Ae (inch) Z1PLB Vc Fractional Hardness Ae x D1 Ap x D1 (SFM) 1/64 1/8 1/4 3/8 1/2 5/8 3/4 1 Profile 310 RPM 75910 9474 4737 3158 2368 1895 1579 1184 ≤ 0.5 ≤ 1.5 (248-372) Fz 0.00003 0.00027 0.0007 0.0014 0.0018 0.0020 0.0022 0.0025 STAINLESS STEELS ≤ 325 Bhn Feed (ipm) 9.1 10.2 13.3 17.7 17.1 15.2 13.9 11.8 M (PH) or 13-8 PH, 15-5 PH, ≤ 35 HRc 250 RPM 61218 7640 3820 2547 1910 1528 1273 955 Z-Carb-AP 17-4 PH, Custom 450 Slot 1 ≤1 (200-300) Fz 0.00003 0.00027 0.0007 0.0014 0.0018 0.0020 0.0022 0.0025 Feed (ipm) 7.3 8.3 10.7 14.3 13.8 12.2 11.2 9.6 Profile 80 RPM 19590 2445 1222 815 611 489 407 306 SUPER ALLOYS ≤ 0.5 ≤ 1.5 (64-96) Fz 0.00003 0.00025 0.0007 0.0013 0.0017 0.0019 0.0020 0.0024 (NICKEL, COBALT, ≤ 300 Bhn Feed (ipm) 2.4 2.4 3.3 4.2 4.2 3.7 3.3 2.9 | IRON BASE) or 65 RPM 15917 1986 993 662 497 397 331 248 Speed & Feed Recommendations Inconel 601, 617, 625, ≤ 32 HRc Slot Incoloy, Monel 400 1 ≤1 Fz 0.00003 0.00025 0.0007 0.0013 0.0017 0.0019 0.0020 0.0024 (52-78) Feed (ipm) 1.9 2.0 2.7 3.4 3.4 3.0 2.7 2.4 Profile 62 RPM 15182 1895 947 632 474 379 316 237 SUPER ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.00002 0.00018 0.0005 0.0009 0.0012 0.0013 0.0014 0.0017 (NICKEL, COBALT, ≤ 400 Bhn (50-74) Feed (ipm) 1.2 1.4 1.8 2.3 2.3 2.0 1.8 1.6 IRON BASE) or Inconel 718, X-750, ≤ 43 HRc 50 RPM 12244 1528 764 509 382 306 255 191 Incoloy, Waspaloy, Slot Hastelloy, Rene 1 ≤1 (40-60) Fz 0.00002 0.00018 0.0005 0.0009 0.0012 0.0013 0.0014 0.0017 S Feed (ipm) 1.0 1.1 1.5 1.8 1.8 1.6 1.4 1.3 Profile 215 RPM 52647 6570 3285 2190 1643 1314 1095 821 TITANIUM ALLOYS ≤ 0.5 ≤ 1.5 (172-258) Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 Pure Ttanium, ≤ 350 Bhn Feed (ipm) 6.3 7.9 10.5 13.1 13.1 11.6 10.5 9.2 Ti6Al4V, or 170 RPM 41628 5195 2598 1732 1299 1039 866 649 Ti6Al2Sn4Zr2Mo, ≤ 38 HRc Slot Ti4Al4Mo2Sn0.5Si 1 ≤1 Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 (136-204) Feed (ipm) 5.0 6.2 8.3 10.4 10.4 9.1 8.3 7.3 TITANIUM ALLOYS Profile 75 RPM 18365 2292 1146 764 573 458 382 287 (DIFFICULT) ≤ 0.5 ≤ 1.5 Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 Ti10Al2Fe3Al, ≤ 440 Bhn (60-90) Feed (ipm) 2.2 2.8 3.7 4.6 4.6 4.0 3.7 3.2 Ti5Al5V5Mo3Cr, or Ti7Al4Mo, ≤ 47 HRc 60 RPM 14692 1834 917 611 458 367 306 229 Ti3Al8V6Cr4Zr4Mo, Slot Ti6Al6V6Sn, Ti15V3 1 ≤1 (48-72) Fz 0.00003 0.0003 0.0008 0.0015 0.0020 0.0022 0.0024 0.0028 Cr3Sn3Al Feed (ipm) 1.8 2.2 2.9 3.7 3.7 3.2 2.9 2.6 Bhn (Brinell) HRc (Rockwell C) rpm = Vc x 3.82 / D1 ipm = Fz x 4 x rpm maximum Slotting Ap for Z1PCR <1/8 diameter and all Z1PLC / Z1PLB is .25 x D1 Tool Wizard maximum Profile Ae for Z1PCR <1/8 diameter and all Z1PLC / Z1PLB is .20 x D1 reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x D1 maximum) CALCULATE APPLICATION PARAMETERS refer to the SGS Tool Wizard for complete technical information (www.sgstool.com) www.sgstool.com www.sgstool.com 13