Каталог SGS высокопроизводительные черновые фрезы - страница 5

Навигация

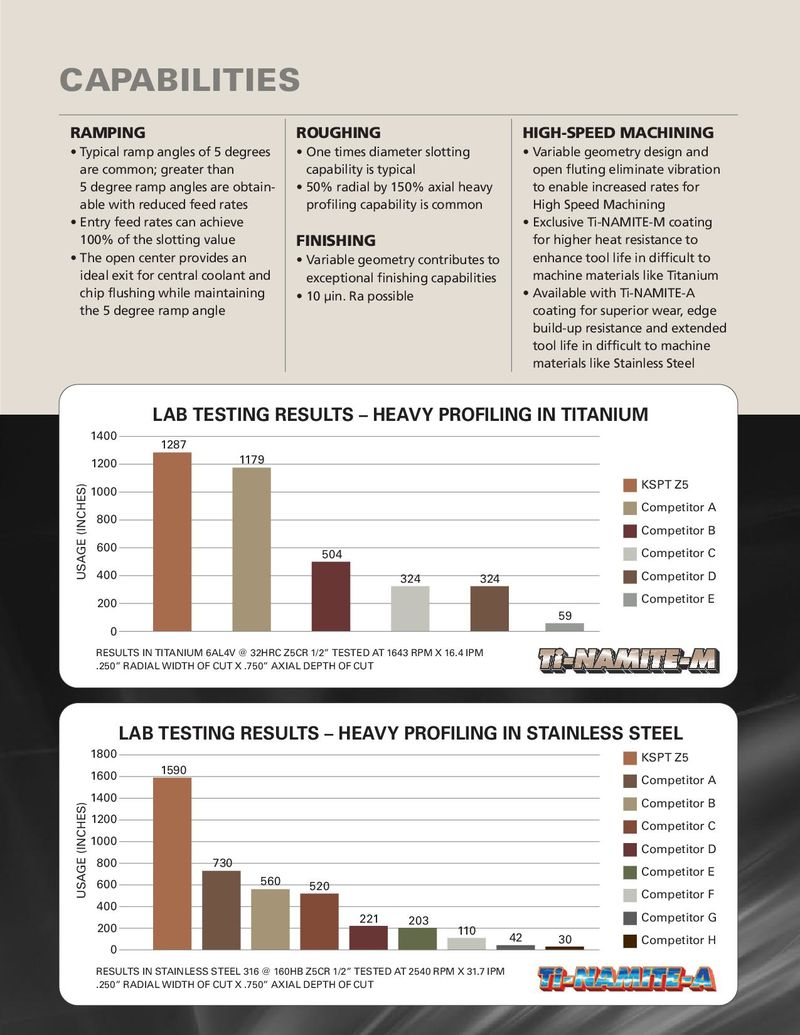

CAPABILITIES RAMPING ROUGHING HIGH-SPEED MACHINING • Typical ramp angles of 5 degrees • One times diameter slotting • Variable geometry design and are common; greater than capability is typical open fluting eliminate vibration 5 degree ramp angles are obtain- • 50% radial by 150% axial heavy to enable increased rates for able with reduced feed rates profiling capability is common High Speed Machining • Entry feed rates can achieve • Exclusive Ti-NAMITE-M coating 100% of the slotting value FINISHING for higher heat resistance to • The open center provides an • Variable geometry contributes to enhance tool life in difficult to ideal exit for central coolant and exceptional finishing capabilities machine materials like Titanium chip flushing while maintaining • 10 µin. Ra possible • Available with Ti-NAMITE-A the 5 degree ramp angle coating for superior wear, edge build-up resistance and extended tool life in difficult to machine materials like Stainless Steel LAB TESTING RESULTS – HEAVY PROFILING IN TITANIUM 1400 1287 1200 1179 USAGE (INCHES) 1000 KSPT Z5 Competitor A 800 Competitor B 600 504 Competitor C 400 324 324 Competitor D 200 Competitor E 59 0 RESULTS IN TITANIUM 6AL4V @ 32HRC Z5CR 1/2” TESTED AT 1643 RPM X 16.4 IPM .250” RADIAL WIDTH OF CUT X .750” AXIAL DEPTH OF CUT LAB TESTING RESULTS – HEAVY PROFILING IN STAINLESS STEEL 1800 KSPT Z5 1600 1590 Competitor A USAGE (INCHES) 1400 Competitor B 1200 Competitor C 1000 Competitor D 800 730 Competitor E 600 560 520 Competitor F 400 200 221 203 Competitor G 110 42 30 Competitor H 0 RESULTS IN STAINLESS STEEL 316 @ 160HB Z5CR 1/2” TESTED AT 2540 RPM X 31.7 IPM .250” RADIAL WIDTH OF CUT X .750” AXIAL DEPTH OF CUT

Каталог SGS фрезы с переменным углом спирали Z-carb

Каталог SGS фрезы с переменным углом спирали Z-carb Каталог SGS микроинструмент

Каталог SGS микроинструмент Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Общий каталог SGS 2018

Общий каталог SGS 2018 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33