Каталог SGS высокопроизводительные черновые фрезы - страница 15

Навигация

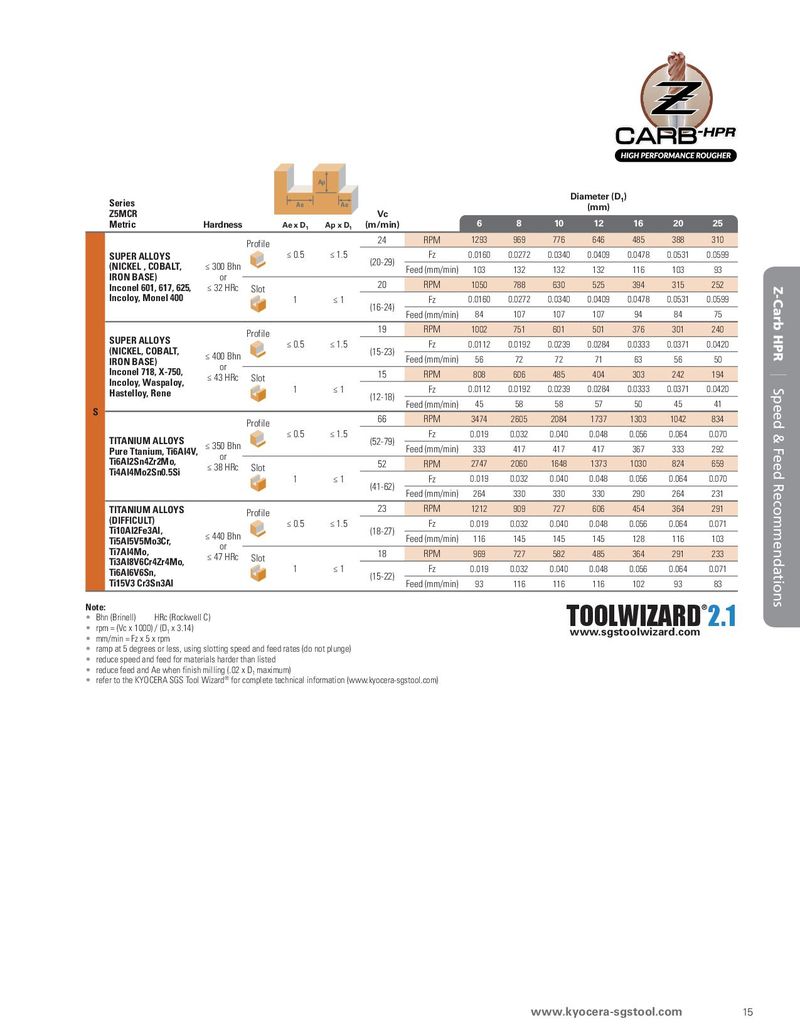

Ap Series Ae Ae Diameter (D1) Z5MCR Vc (mm) Metric Hardness Ae x D1 Ap x D1 (m/min) 6 8 10 12 16 20 25 Profile 24 RPM 1293 969 776 646 485 388 310 SUPER ALLOYS ≤ 0.5 ≤ 1.5 (20-29) Fz 0.0160 0.0272 0.0340 0.0409 0.0478 0.0531 0.0599 (NICKEL , COBALT, ≤ 300 Bhn Feed (mm/min) 103 132 132 132 116 103 93 IRON BASE) or 20 RPM 1050 788 630 525 394 315 252 Inconel 601, 617, 625, ≤ 32 HRc Slot Z-Carb HPR Incoloy, Monel 400 1 ≤1 (16-24) Fz 0.0160 0.0272 0.0340 0.0409 0.0478 0.0531 0.0599 Feed (mm/min) 84 107 107 107 94 84 75 Profile 19 RPM 1002 751 601 501 376 301 240 SUPER ALLOYS ≤ 0.5 ≤ 1.5 Fz 0.0112 0.0192 0.0239 0.0284 0.0333 0.0371 0.0420 (NICKEL, COBALT, ≤ 400 Bhn (15-23) Feed (mm/min) 56 72 72 71 63 56 50 IRON BASE) or Inconel 718, X-750, ≤ 43 HRc Slot 15 RPM 808 606 485 404 303 242 194 | Incoloy, Waspaloy, 1 ≤1 Fz 0.0112 0.0192 0.0239 0.0284 0.0333 0.0371 0.0420 Hastelloy, Rene (12-18) Speed & Feed Recommendations S Feed (mm/min) 45 58 58 57 50 45 41 Profile 66 RPM 3474 2605 2084 1737 1303 1042 834 TITANIUM ALLOYS ≤ 0.5 ≤ 1.5 (52-79) Fz 0.019 0.032 0.040 0.048 0.056 0.064 0.070 Pure Ttanium, Ti6Al4V, ≤ 350 Bhn Feed (mm/min) 333 417 417 417 367 333 292 Ti6Al2Sn4Zr2Mo, or 52 RPM 2747 2060 1648 1373 1030 824 659 Ti4Al4Mo2Sn0.5Si ≤ 38 HRc Slot 1 ≤1 (41-62) Fz 0.019 0.032 0.040 0.048 0.056 0.064 0.070 Feed (mm/min) 264 330 330 330 290 264 231 TITANIUM ALLOYS Profile 23 RPM 1212 909 727 606 454 364 291 (DIFFICULT) ≤ 0.5 ≤ 1.5 Fz 0.019 0.032 0.040 0.048 0.056 0.064 0.071 Ti10Al2Fe3Al, ≤ 440 Bhn (18-27) Feed (mm/min) 116 145 145 145 128 116 103 Ti5Al5V5Mo3Cr, or Ti7Al4Mo, ≤ 47 HRc Slot 18 RPM 969 727 582 485 364 291 233 Ti3Al8V6Cr4Zr4Mo, 1 ≤1 Fz 0.019 0.032 0.040 0.048 0.056 0.064 0.071 Ti6Al6V6Sn, (15-22) Ti15V3 Cr3Sn3Al Feed (mm/min) 93 116 116 116 102 93 83 Note: TOOLWIZARD®2.1 • Bhn (Brinell) HRc (Rockwell C) • rpm = (Vc x 1000) / (D1 x 3.14) www.sgstoolwizard.com • mm/min = Fz x 5 x rpm • ramp at 5 degrees or less, using slotting speed and feed rates (do not plunge) • reduce speed and feed for materials harder than listed • reduce feed and Ae when finish milling (.02 x D1 maximum) • refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocera-sgstool.com 15

Каталог SGS фрезы с переменным углом спирали Z-carb

Каталог SGS фрезы с переменным углом спирали Z-carb Каталог SGS микроинструмент

Каталог SGS микроинструмент Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Общий каталог SGS 2018

Общий каталог SGS 2018 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33