Каталог SGS микро инструмент 2021 - страница 97

Навигация

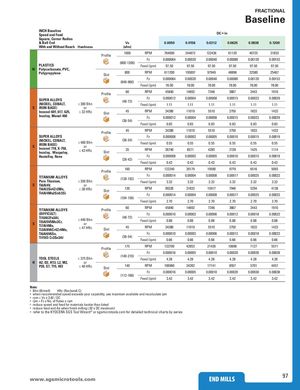

FRACTIONAL Baseline INCH BaselineSpeed and Feed DC • in Square, Corner Radius & Ball End Vc 0.0050 0.0156 0.0312 0.0625 0.0938 0.1200 With and Without Reach Hardness (sfm) Profile 1000 RPM 764000 244872 122436 61120 40725 31833 Fz 0.000064 0.00020 0.00040 0.00080 0.00120 0.00153 PLASTICS (800-1200) Feed (ipm) 97.50 97.50 97.50 97.50 97.50 97.50 N Polycarbonate, PVC, Polypropylene Slot 800 RPM 611200 195897 97949 48896 32580 25467 Fz 0.000064 0.00020 0.00040 0.00080 0.00120 0.00153 (640-960) Feed (ipm) 78.00 78.00 78.00 78.00 78.00 78.00 Profile 60 RPM 45840 14692 7346 3667 2443 1910 SUPER ALLOYS(NICKEL, COBALT, ≤ 300 Bhn Fz 0.000012 0.00004 0.00008 0.00015 0.00023 0.00029(48-72)Feed (ipm)1.111.111.111.111.111.11 S IRON BASE) or Inconel 601, 617, 625, ≤ 32 HRcIncoloy, Monel 400Slot45 RPM 34380 11019 5510 2750 1833 1433Fz0.0000120.000040.000080.000150.000230.00029 (36-54) Feed (ipm) 0.83 0.83 0.83 0.83 0.83 0.83 Profile 45 RPM 34380 11019 5510 2750 1833 1433 SUPER ALLOYS Fz 0.000008 0.00003 0.00005 0.00010 0.00015 0.00019 (NICKEL, COBALT,SIRON BASE)Inconel 718, X-750,Incoloy, Waspaloy,≤ 400 Bhnor≤ 43 HRcSlot(36-54)Feed (ipm)0.5535RPM267400.5585710.5542850.5521390.5514250.551114 Hastelloy, Rene Fz 0.000008 0.00003 0.00005 0.00010 0.00015 0.00019 (28-42) Feed (ipm) 0.43 0.43 0.43 0.43 0.43 0.43 Profile 160 RPM 122240 39179 19590 9779 6516 5093 TITANIUM ALLOYSPure Titanium, ≤ 350 Bhn Fz 0.000014 0.00004 0.00008 0.00017 0.00025 0.00033(128-192)Feed (ipm)3.323.323.323.323.323.32 S Ti6Al4V, or Ti6Al2Sn4Zr2Mo,Ti4Al4Mo2Sn0.5Si≤ 38 HRc Slot 130 RPM 99320 31833 15917 7946 5294 4138Fz0.0000140.000040.000080.000170.000250.00033 (104-156) Feed (ipm) 2.70 2.70 2.70 2.70 2.70 2.70 TITANIUM ALLOYS Profile 60 RPM 45840 14692 7346 3667 2443 1910 (DIFFICULT) Fz 0.000010 0.00003 0.00006 0.00012 0.00018 0.00023 Ti10Al2Fe3Al,STi5Al5V5Mo3Cr,Ti7Al4Mo,Ti3Al8V6Cr4Zr4Mo,≤ 440 Bhnor≤ 47 HRcSlot(48-72)Feed (ipm)0.880.8845RPM34380110190.8855100.882750 0.881833 0.881433 Ti6Al6V6Sn, Fz 0.000010 0.00003 0.00006 0.00012 0.00018 0.00023 Ti15V3 Cr3Sn3Al (36-54) Feed (ipm) 0.66 0.66 0.66 0.66 0.66 0.66 Profile 175 RPM 133700 42853 21426 10696 7127 5571 Fz 0.000016 0.00005 0.00010 0.00020 0.00030 0.00038 TOOL STEELS ≤ 375 Bhn (140-210) Feed (ipm) 4.28 4.28 4.28 4.28 4.28 4.28 H A2, D2, H13, L2, M2, or P20, S7, T15, W2 ≤ 40 HRc Slot 140 RPM 106960 34282 17141 8557 5701 4457 Fz 0.000016 0.00005 0.00010 0.00020 0.00030 0.00038 (112-168) Feed (ipm) 3.42 3.42 3.42 3.42 3.42 3.42 Note: • Bhn (Brinell) HRc (Rockwell C) • when recommended speed exceeds your capability, use maximum available and recalculate ipm • rpm = Vc x 3.82 / DC • ipm = Fz x No. of flutes x rpm • reduce speed and feed for materials harder than listed • reduce feed and Ae when finish milling (.02 x DC maximum) • refer to the KYOCERA SGS Tool Wizard® or sgsmicrotools.com for detailed technical charts by series www.sgsmicErNoDtoMoIlLsL.cSom END MILLS 97

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33