Каталог SGS микро инструмент 2021 - страница 109

Навигация

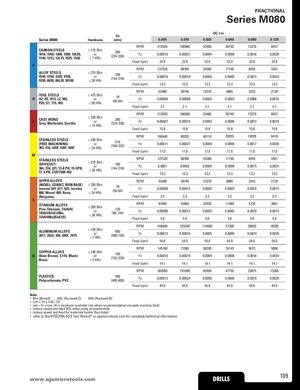

FRACTIONAL Series M080 DC • in Vc Series M080 Hardness (sfm) 0.005 0.010 0.020 0.040 0.080 0.125 RPM 213920 106960 53480 26740 13370 8557 CARBON STEELS ≤ 175 Bhn1018, 1040, 1080, 1090, 10L50,or1140, 1212, 12L15, 1525, 1536≤ 7 HRc280(224-336)Fz0.000100.000210.00040.00080.00160.0026 Feed (ipm) 22.0 22.0 22.0 22.0 22.0 22.0 P RPM 137520 68760 34380 17190 8595 5501 ALLOY STEELS4140, 4150, 4320, 5120,5150, 8630, 86L20, 50100≤ 275 Bhnor≤ 28 HRc180(144-216)Fz0.000100.00019 0.0004 0.0008 0.0015 0.0024 Feed (ipm) 13.3 13.3 13.3 13.3 13.3 13.3 RPM 53480 26740 13370 6685 3343 2139 TOOL STEELSHA2, D2, H13, L2, M2,P20, S7, T15, W2≤ 475 Bhnor≤ 50 HRc70(56-84)Fz 0.00004 0.00008 0.0002 0.0003 0.0006 0.0010 Feed (ipm) 2.1 2.1 2.1 2.1 2.1 2.1 RPM 213920 106960 53480 26740 13370 8557 K CAST IRONSGray, Malleable, Ductile≤ 220 Bhnor≤ 19 HRc 280(224-336) Fz 0.00007 0.00015 0.0003 0.0006 0.0012 0.0018 Feed (ipm) 15.8 15.8 15.8 15.8 15.8 15.8 RPM 160440 80220 40110 20055 10028 6418 STAINLESS STEELS(FREE MACHINING)303, 416, 420F, 430F, 440F≤ 250 Bhnor≤ 24 HRc210(168-252)Fz0.000110.00021 0.0004 0.0008 0.0017 0.0026 Feed (ipm) 17.0 17.0 17.0 17.0 17.0 17.0 M STAINLESS STEELS(DIFFICULT)304, 316, 321, 13-8 PH, 15-5PH,17-4 PH, CUSTOM 450≤ 275 Bhnor≤ 28 HRc180(144-216)RPMFzFeed (ipm)1375200.000113.3687600.000213.3343800.000413.3171900.000813.385950.001513.355010.002413.3 SUPER ALLOYS RPM 53480 26740 13370 6685 3343 2139 (NICKEL, COBALT, IRON BASE) ≤ 320 BhnInconel 601, 617, 625, Incoloyor800, Monel 400, Rene,≤ 34 HRc70(56-84)Fz0.000060.000120.00020.00050.0010 0.0015 Waspaloy Feed (ipm) 3.2 3.2 3.2 3.2 3.2 3.2 S TITANIUM ALLOYSPure Titanium, Ti6Al4V,Ti6Al2Sn4Zr2Mo,Ti4Al4Mo2Sn0.5SiRPM 91680 45840 22920 11460 5730 3667≤ 350 Bhnor≤ 38 HRc120(96-144)Fz0.000060.000120.00020.00050.00100.0015Feed (ipm)5.65.65.65.65.65.6 RPM 458400 229200 114600 57300 28650 18336 ALUMINUM ALLOYS2017, 2024, 356, 6061, 7075≤ 150 Bhnor≤ 7 HRc600(480-720)Fz 0.00012 0.00024 0.0005 0.0009 0.0019 0.0029 Feed (ipm) 54.0 54.0 54.0 54.0 54.0 54.0 RPM 145160 72580 36290 18145 9073 5806 COPPER ALLOYSNAlum Bronze, C110, MuntzBrass≤ 140 Bhnor≤ 3 HRc190(152-228)Fz 0.00010 0.00019 0.0004 0.0008 0.0016 0.0024 Feed (ipm) 14.1 14.1 14.1 14.1 14.1 14.1 RPM 382000 191000 95500 47750 23875 15280 PLASTICSPolycarbonate, PVC 500(400-600) Fz 0.00012 0.00024 0.0005 0.0009 0.0019 0.0029 Feed (ipm) 45.0 45.0 45.0 45.0 45.0 45.0 Note: • Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) • rpm = Vc x 3.82 / DC • ipm = Fr x rpm (Fr x maximum available rpm when recommendation exceeds machine limit) • reduce speed and feed 30% when using uncoated drills • reduce speed and feed for materials harder than listed • refer to the KYOCERA SGS Tool Wizard® or sgsmicrotools.com for complete technical information www.sgsmicrDoRtoILoLlSs.com DRILLS 109

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33