Каталог SGS фрезы для алюминия S-carb - страница 7

Навигация

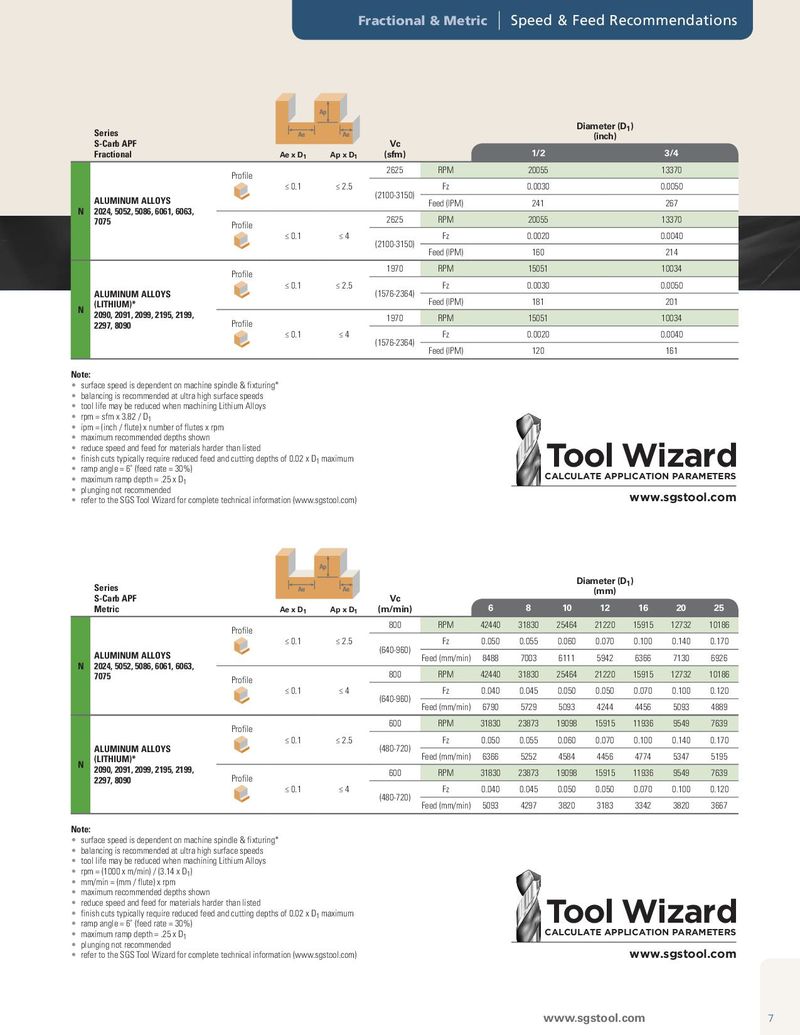

| Fractional & Metric Speed & Feed Recommendations Ap Series Ae Ae Diameter (D1) S-Carb APF Vc (inch) Fractional Ae x D1 Ap x D1 (sfm) 1/2 3/4 Profile 2625 RPM 20055 13370 ≤ 0.1 ≤ 2.5 (2100-3150) Fz 0.0030 0.0050 ALUMINUM ALLOYS Feed (IPM) 241 267 N 2024, 5052, 5086, 6061, 6063, 2625 RPM 20055 13370 7075 Profile ≤ 0.1 ≤4 (2100-3150) Fz 0.0020 0.0040 Feed (IPM) 160 214 Profile 1970 RPM 15051 10034 ≤ 0.1 ≤ 2.5 (1576-2364) Fz 0.0030 0.0050 ALUMINUM ALLOYS Feed (IPM) 181 201 N (LITHIUM)* 2090, 2091, 2099, 2195, 2199, 1970 RPM 15051 10034 2297, 8090 Profile ≤ 0.1 ≤4 (1576-2364) Fz 0.0020 0.0040 Feed (IPM) 120 161 Note: • surface speed is dependent on machine spindle & fixturing* • balancing is recommended at ultra high surface speeds • tool life may be reduced when machining Lithium Alloys • rpm = sfm x 3.82 / D1 • ipm = (inch / flute) x number of flutes x rpm • maximum recommended depths shown • reduce speed and feed for materials harder than listed Tool Wizard • finish cuts typically require reduced feed and cutting depths of 0.02 x D1 maximum • ramp angle = 6˚ (feed rate = 30%) CALCULATE APPLICATION PARAMETERS • maximum ramp depth = .25 x D1 • plunging not recommended www.sgstool.com • refer to the SGS Tool Wizard for complete technical information (www.sgstool.com) Ap Series Ae Ae Diameter (D1) S-Carb APF Vc (mm) Metric Ae x D1 Ap x D1 (m/min) 6 8 10 12 16 20 25 Profile 800 RPM 42440 31830 25464 21220 15915 12732 10186 ≤ 0.1 ≤ 2.5 (640-960) Fz 0.050 0.055 0.060 0.070 0.100 0.140 0.170 ALUMINUM ALLOYS Feed (mm/min) 8488 7003 6111 5942 6366 7130 6926 N 2024, 5052, 5086, 6061, 6063, 800 RPM 42440 31830 25464 21220 15915 12732 10186 7075 Profile ≤ 0.1 ≤4 (640-960) Fz 0.040 0.045 0.050 0.050 0.070 0.100 0.120 Feed (mm/min) 6790 5729 5093 4244 4456 5093 4889 Profile 600 RPM 31830 23873 19098 15915 11936 9549 7639 ≤ 0.1 ≤ 2.5 (480-720) Fz 0.050 0.055 0.060 0.070 0.100 0.140 0.170 ALUMINUM ALLOYS Feed (mm/min) 6366 5252 4584 4456 4774 5347 5195 N (LITHIUM)* 2090, 2091, 2099, 2195, 2199, 600 RPM 31830 23873 19098 15915 11936 9549 7639 2297, 8090 Profile ≤ 0.1 ≤4 (480-720) Fz 0.040 0.045 0.050 0.050 0.070 0.100 0.120 Feed (mm/min) 5093 4297 3820 3183 3342 3820 3667 Note: • surface speed is dependent on machine spindle & fixturing* • balancing is recommended at ultra high surface speeds • tool life may be reduced when machining Lithium Alloys • rpm = (1000 x m/min) / (3.14 x D1) • mm/min = (mm / flute) x rpm • maximum recommended depths shown • reduce speed and feed for materials harder than listed Tool Wizard • finish cuts typically require reduced feed and cutting depths of 0.02 x D1 maximum • ramp angle = 6˚ (feed rate = 30%) • maximum ramp depth = .25 x D1 CALCULATE APPLICATION PARAMETERS • plunging not recommended • refer to the SGS Tool Wizard for complete technical information (www.sgstool.com) www.sgstool.com www.sgstool.com 7

Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series