Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb - страница 9

Навигация

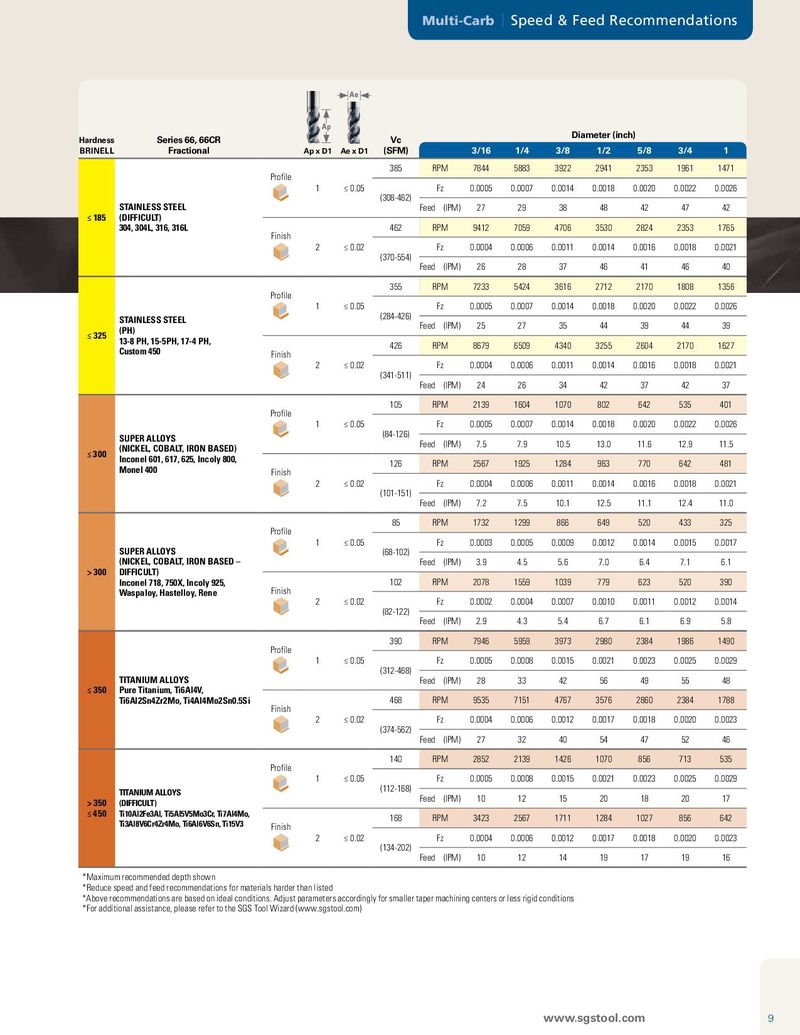

Multi-Carb | Speed & Feed Recommendations Ae Ap Hardness Series 66, 66CR Vc Diameter (inch) BRINELL Fractional Ap x D1 Ae x D1 (SFM) 3/16 1/4 3/8 1/2 5/8 3/4 1 385 RPM 7844 5883 3922 2941 2353 1961 1471 Profile 1 ≤ 0.05 Fz 0.0005 0.0007 0.0014 0.0018 0.0020 0.0022 0.0026 (308-462) STAINLESS STEEL Feed (IPM) 27 29 38 48 42 47 42 ≤ 185 (DIFFICULT) 304, 304L, 316, 316L 462 RPM 9412 7059 4706 3530 2824 2353 1765 Finish 2 ≤ 0.02 Fz 0.0004 0.0006 0.0011 0.0014 0.0016 0.0018 0.0021 (370-554) Feed (IPM) 26 28 37 46 41 46 40 355 RPM 7233 5424 3616 2712 2170 1808 1356 Profile 1 ≤ 0.05 Fz 0.0005 0.0007 0.0014 0.0018 0.0020 0.0022 0.0026 STAINLESS STEEL (284-426) (PH) Feed (IPM) 25 27 35 44 39 44 39 ≤ 325 13-8 PH, 15-5PH, 17-4 PH, Custom 450 426 RPM 8679 6509 4340 3255 2604 2170 1627 Finish 2 ≤ 0.02 Fz 0.0004 0.0006 0.0011 0.0014 0.0016 0.0018 0.0021 (341-511) Feed (IPM) 24 26 34 42 37 42 37 105 RPM 2139 1604 1070 802 642 535 401 Profile 1 ≤ 0.05 Fz 0.0005 0.0007 0.0014 0.0018 0.0020 0.0022 0.0026 SUPER ALLOYS (84-126) (NICKEL, COBALT, IRON BASED) Feed (IPM) 7.5 7.9 10.5 13.0 11.6 12.9 11.5 ≤ 300 Inconel 601, 617, 625, Incoly 800, Monel 400 126 RPM 2567 1925 1284 963 770 642 481 Finish 2 ≤ 0.02 Fz 0.0004 0.0006 0.0011 0.0014 0.0016 0.0018 0.0021 (101-151) Feed (IPM) 7.2 7.5 10.1 12.5 11.1 12.4 11.0 85 RPM 1732 1299 866 649 520 433 325 Profile 1 ≤ 0.05 Fz 0.0003 0.0005 0.0009 0.0012 0.0014 0.0015 0.0017 SUPER ALLOYS (68-102) (NICKEL, COBALT, IRON BASED – Feed (IPM) 3.9 4.5 5.6 7.0 6.4 7.1 6.1 > 300 DIFFICULT) Inconel 718, 750X, Incoly 925, 102 RPM 2078 1559 1039 779 623 520 390 Waspaloy, Hastelloy, Rene Finish 2 ≤ 0.02 Fz 0.0002 0.0004 0.0007 0.0010 0.0011 0.0012 0.0014 (82-122) Feed (IPM) 2.9 4.3 5.4 6.7 6.1 6.9 5.8 390 RPM 7946 5959 3973 2980 2384 1986 1490 Profile 1 ≤ 0.05 Fz 0.0005 0.0008 0.0015 0.0021 0.0023 0.0025 0.0029 (312-468) TITANIUM ALLOYS Feed (IPM) 28 33 42 56 49 55 48 ≤ 350 Pure Titanium, Ti6Al4V, Ti6Al2Sn4Zr2Mo, Ti4Al4Mo2Sn0.5Si 468 RPM 9535 7151 4767 3576 2860 2384 1788 Finish 2 ≤ 0.02 Fz 0.0004 0.0006 0.0012 0.0017 0.0018 0.0020 0.0023 (374-562) Feed (IPM) 27 32 40 54 47 52 46 140 RPM 2852 2139 1426 1070 856 713 535 Profile 1 ≤ 0.05 Fz 0.0005 0.0008 0.0015 0.0021 0.0023 0.0025 0.0029 TITANIUM ALLOYS (112-168) > 350 (DIFFICULT) Feed (IPM) 10 12 15 20 18 20 17 ≤ 450 Ti10Al2Fe3Al, Ti5Al5V5Mo3Cr, Ti7Al4Mo, 168 RPM 3423 2567 1711 1284 1027 856 642 Ti3Al8V6Cr4Zr4Mo, Ti6Al6V6Sn, Ti15V3 Finish 2 ≤ 0.02 Fz 0.0004 0.0006 0.0012 0.0017 0.0018 0.0020 0.0023 (134-202) Feed (IPM) 10 12 14 19 17 19 16 *Maximum recommended depth shown *Reduce speed and feed recommendations for materials harder than listed *Above recommendations are based on ideal conditions. Adjust parameters accordingly for smaller taper machining centers or less rigid conditions *For additional assistance, please refer to the SGS Tool Wizard (www.sgstool.com) www.sgstool.com 9

Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS микроинструмент

Каталог SGS микроинструмент Общий каталог SGS 2018

Общий каталог SGS 2018 Каталог SGS инструмент для сверления

Каталог SGS инструмент для сверления Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия