Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb - страница 11

Навигация

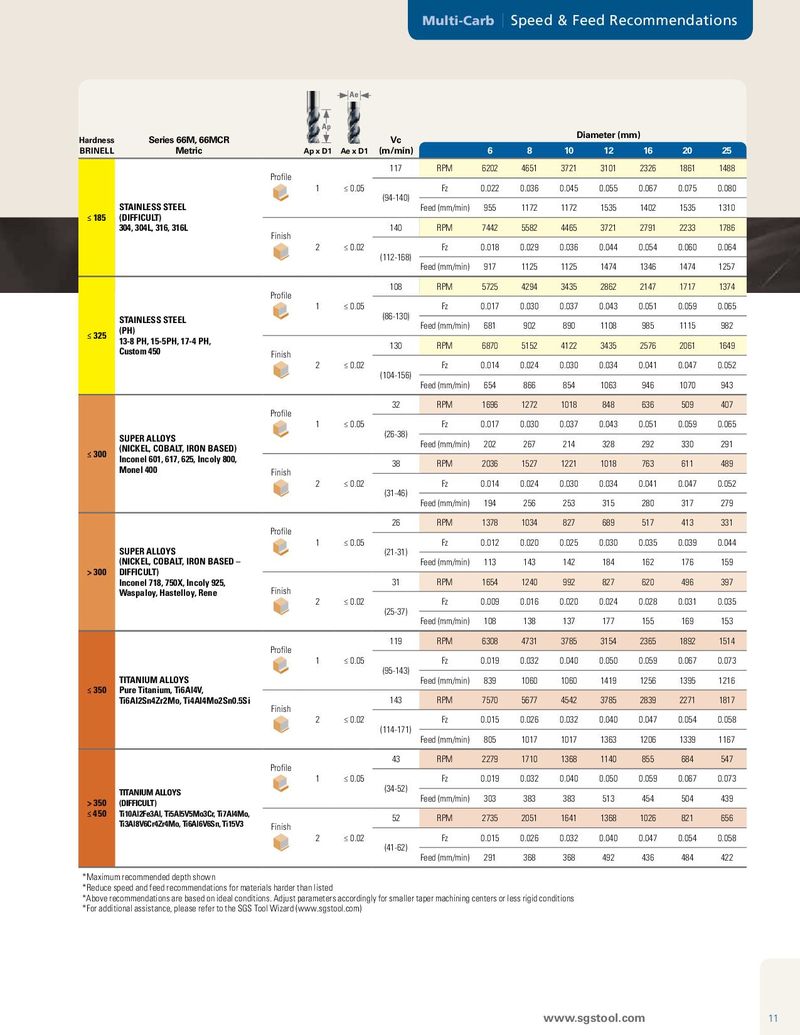

Multi-Carb | Speed & Feed Recommendations Ae Ap Hardness Series 66M, 66MCR Vc Diameter (mm) BRINELL Metric Ap x D1 Ae x D1 (m/min) 6 8 10 12 16 20 25 117 RPM 6202 4651 3721 3101 2326 1861 1488 Profile 1 ≤ 0.05 Fz 0.022 0.036 0.045 0.055 0.067 0.075 0.080 (94-140) STAINLESS STEEL Feed (mm/min) 955 1172 1172 1535 1402 1535 1310 ≤ 185 (DIFFICULT) 304, 304L, 316, 316L 140 RPM 7442 5582 4465 3721 2791 2233 1786 Finish 2 ≤ 0.02 Fz 0.018 0.029 0.036 0.044 0.054 0.060 0.064 (112-168) Feed (mm/min) 917 1125 1125 1474 1346 1474 1257 108 RPM 5725 4294 3435 2862 2147 1717 1374 Profile 1 ≤ 0.05 Fz 0.017 0.030 0.037 0.043 0.051 0.059 0.065 STAINLESS STEEL (86-130) (PH) Feed (mm/min) 681 902 890 1108 985 1115 982 ≤ 325 13-8 PH, 15-5PH, 17-4 PH, Custom 450 130 RPM 6870 5152 4122 3435 2576 2061 1649 Finish 2 ≤ 0.02 Fz 0.014 0.024 0.030 0.034 0.041 0.047 0.052 (104-156) Feed (mm/min) 654 866 854 1063 946 1070 943 32 RPM 1696 1272 1018 848 636 509 407 Profile 1 ≤ 0.05 Fz 0.017 0.030 0.037 0.043 0.051 0.059 0.065 SUPER ALLOYS (26-38) (NICKEL, COBALT, IRON BASED) Feed (mm/min) 202 267 214 328 292 330 291 ≤ 300 Inconel 601, 617, 625, Incoly 800, Monel 400 38 RPM 2036 1527 1221 1018 763 611 489 Finish 2 ≤ 0.02 Fz 0.014 0.024 0.030 0.034 0.041 0.047 0.052 (31-46) Feed (mm/min) 194 256 253 315 280 317 279 26 RPM 1378 1034 827 689 517 413 331 Profile 1 ≤ 0.05 Fz 0.012 0.020 0.025 0.030 0.035 0.039 0.044 SUPER ALLOYS (21-31) (NICKEL, COBALT, IRON BASED – Feed (mm/min) 113 143 142 184 162 176 159 > 300 DIFFICULT) Inconel 718, 750X, Incoly 925, 31 RPM 1654 1240 992 827 620 496 397 Waspaloy, Hastelloy, Rene Finish 2 ≤ 0.02 Fz 0.009 0.016 0.020 0.024 0.028 0.031 0.035 (25-37) Feed (mm/min) 108 138 137 177 155 169 153 119 RPM 6308 4731 3785 3154 2365 1892 1514 Profile 1 ≤ 0.05 Fz 0.019 0.032 0.040 0.050 0.059 0.067 0.073 (95-143) TITANIUM ALLOYS Feed (mm/min) 839 1060 1060 1419 1256 1395 1216 ≤ 350 Pure Titanium, Ti6Al4V, Ti6Al2Sn4Zr2Mo, Ti4Al4Mo2Sn0.5Si 143 RPM 7570 5677 4542 3785 2839 2271 1817 Finish 2 ≤ 0.02 Fz 0.015 0.026 0.032 0.040 0.047 0.054 0.058 (114-171) Feed (mm/min) 805 1017 1017 1363 1206 1339 1167 43 RPM 2279 1710 1368 1140 855 684 547 Profile 1 ≤ 0.05 Fz 0.019 0.032 0.040 0.050 0.059 0.067 0.073 TITANIUM ALLOYS (34-52) > 350 (DIFFICULT) Feed (mm/min) 303 383 383 513 454 504 439 ≤ 450 Ti10Al2Fe3Al, Ti5Al5V5Mo3Cr, Ti7Al4Mo, 52 RPM 2735 2051 1641 1368 1026 821 656 Ti3Al8V6Cr4Zr4Mo, Ti6Al6V6Sn, Ti15V3 Finish 2 ≤ 0.02 Fz 0.015 0.026 0.032 0.040 0.047 0.054 0.058 (41-62) Feed (mm/min) 291 368 368 492 436 484 422 *Maximum recommended depth shown *Reduce speed and feed recommendations for materials harder than listed *Above recommendations are based on ideal conditions. Adjust parameters accordingly for smaller taper machining centers or less rigid conditions *For additional assistance, please refer to the SGS Tool Wizard (www.sgstool.com) www.sgstool.com 11

Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS микроинструмент

Каталог SGS микроинструмент Общий каталог SGS 2018

Общий каталог SGS 2018 Каталог SGS инструмент для сверления

Каталог SGS инструмент для сверления Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия