Каталог SGS инструмент для сверления - страница 38

Навигация

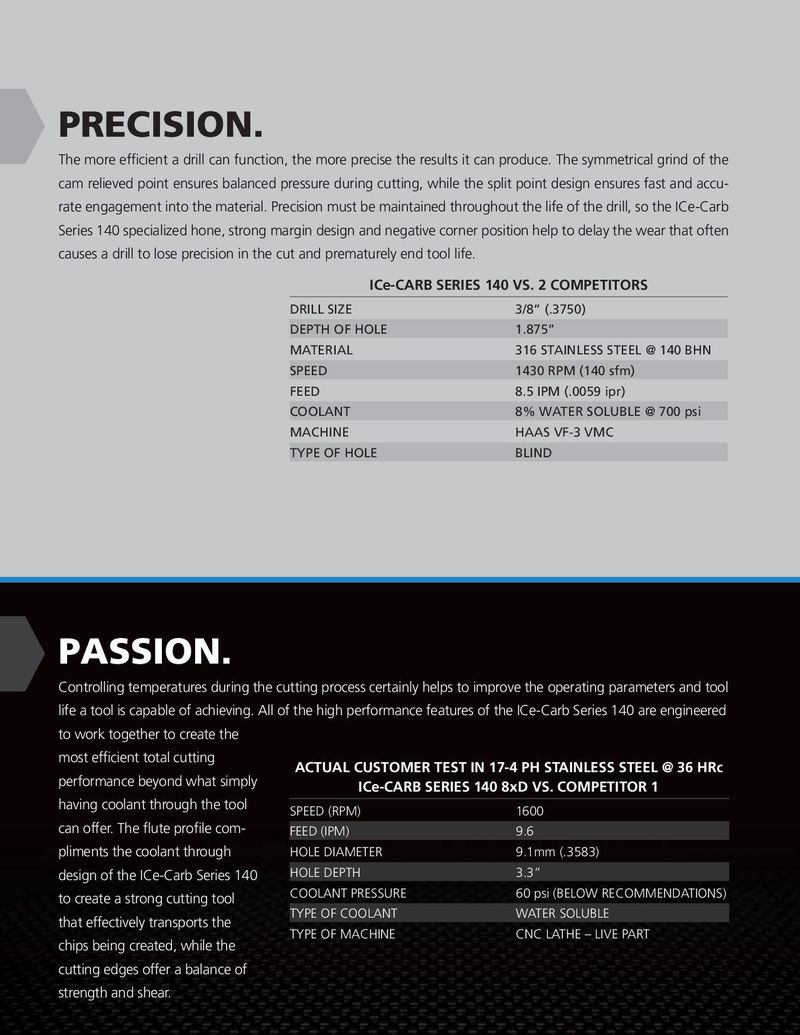

PRECISION. The more efficient a drill can function, the more precise the results it can produce. The symmetrical grind of the cam relieved point ensures balanced pressure during cutting, while the split point design ensures fast and accu- rate engagement into the material. Precision must be maintained throughout the life of the drill, so the ICe-Carb Series 140 specialized hone, strong margin design and negative corner position help to delay the wear that often causes a drill to lose precision in the cut and prematurely end tool life. ICe-CARB SERIES 140 VS. 2 COMPETITORS DRILL SIZE 3/8” (.3750) DEPTH OF HOLE 1.875” MATERIAL 316 STAINLESS STEEL @ 140 BHN SPEED 1430 RPM (140 sfm) FEED 8.5 IPM (.0059 ipr) COOLANT 8% WATER SOLUBLE @ 700 psi MACHINE HAAS VF-3 VMC TYPE OF HOLE BLIND PASSION. Controlling temperatures during the cutting process certainly helps to improve the operating parameters and tool life a tool is capable of achieving. All of the high performance features of the ICe-Carb Series 140 are engineered to work together to create the most efficient total cutting ACTUAL CUSTOMER TEST IN 17-4 PH STAINLESS STEEL @ 36 HRc performance beyond what simply ICe-CARB SERIES 140 8xD VS. COMPETITOR 1 having coolant through the tool SPEED (RPM) 1600 can offer. The flute profile com- FEED (IPM) 9.6 pliments the coolant through HOLE DIAMETER 9.1mm (.3583) design of the ICe-Carb Series 140 HOLE DEPTH 3.3” to create a strong cutting tool COOLANT PRESSURE 60 psi (BELOW RECOMMENDATIONS) that effectively transports the TYPE OF COOLANT WATER SOLUBLE chips being created, while the TYPE OF MACHINE CNC LATHE – LIVE PART cutting edges offer a balance of strength and shear. 38 www.kyocera-sgstool.com

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb

Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb Каталог SGS микроинструмент

Каталог SGS микроинструмент Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb