Каталог SGS инструмент для сверления - страница 18

Навигация

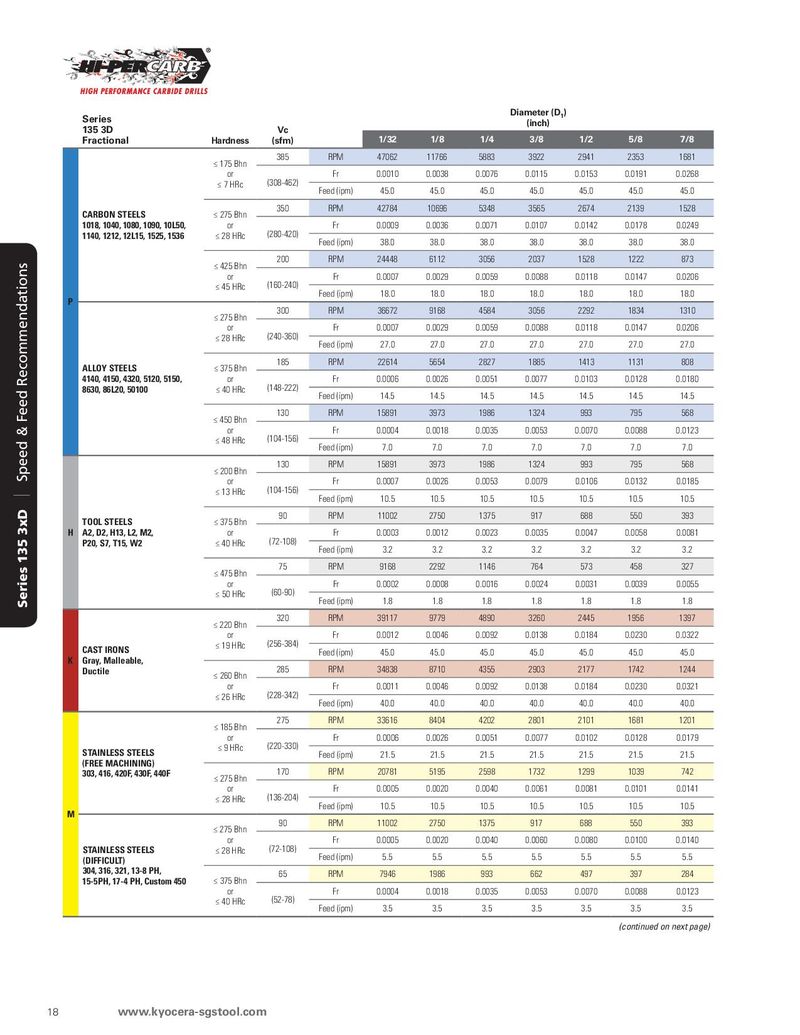

Series Diameter (D1) 135 3D Vc (inch) Fractional Hardness (sfm) 1/32 1/8 1/4 3/8 1/2 5/8 7/8 ≤ 175 Bhn 385 RPM 47062 11766 5883 3922 2941 2353 1681 or Fr 0.0010 0.0038 0.0076 0.0115 0.0153 0.0191 0.0268 ≤ 7 HRc (308-462) Feed (ipm) 45.0 45.0 45.0 45.0 45.0 45.0 45.0 CARBON STEELS ≤ 275 Bhn 350 RPM 42784 10696 5348 3565 2674 2139 1528 1018, 1040, 1080, 1090, 10L50, or Fr 0.0009 0.0036 0.0071 0.0107 0.0142 0.0178 0.0249 1140, 1212, 12L15, 1525, 1536 ≤ 28 HRc (280-420) Feed (ipm) 38.0 38.0 38.0 38.0 38.0 38.0 38.0 Speed & Feed Recommendations ≤ 425 Bhn 200 RPM 24448 6112 3056 2037 1528 1222 873 or Fr 0.0007 0.0029 0.0059 0.0088 0.0118 0.0147 0.0206 ≤ 45 HRc (160-240) Feed (ipm) 18.0 18.0 18.0 18.0 18.0 18.0 18.0 P ≤ 275 Bhn 300 RPM 36672 9168 4584 3056 2292 1834 1310 or Fr 0.0007 0.0029 0.0059 0.0088 0.0118 0.0147 0.0206 ≤ 28 HRc (240-360) Feed (ipm) 27.0 27.0 27.0 27.0 27.0 27.0 27.0 ALLOY STEELS ≤ 375 Bhn 185 RPM 22614 5654 2827 1885 1413 1131 808 4140, 4150, 4320, 5120, 5150, or Fr 0.0006 0.0026 0.0051 0.0077 0.0103 0.0128 0.0180 8630, 86L20, 50100 ≤ 40 HRc (148-222) Feed (ipm) 14.5 14.5 14.5 14.5 14.5 14.5 14.5 ≤ 450 Bhn 130 RPM 15891 3973 1986 1324 993 795 568 or Fr 0.0004 0.0018 0.0035 0.0053 0.0070 0.0088 0.0123 ≤ 48 HRc (104-156) Feed (ipm) 7.0 7.0 7.0 7.0 7.0 7.0 7.0 ≤ 200 Bhn 130 RPM 15891 3973 1986 1324 993 795 568 or Fr 0.0007 0.0026 0.0053 0.0079 0.0106 0.0132 0.0185 | ≤ 13 HRc (104-156) Feed (ipm) 10.5 10.5 10.5 10.5 10.5 10.5 10.5 Series 135 3xD TOOL STEELS ≤ 375 Bhn 90 RPM 11002 2750 1375 917 688 550 393 H A2, D2, H13, L2, M2, or Fr 0.0003 0.0012 0.0023 0.0035 0.0047 0.0058 0.0081 P20, S7, T15, W2 ≤ 40 HRc (72-108) Feed (ipm) 3.2 3.2 3.2 3.2 3.2 3.2 3.2 ≤ 475 Bhn 75 RPM 9168 2292 1146 764 573 458 327 or Fr 0.0002 0.0008 0.0016 0.0024 0.0031 0.0039 0.0055 ≤ 50 HRc (60-90) Feed (ipm) 1.8 1.8 1.8 1.8 1.8 1.8 1.8 ≤ 220 Bhn 320 RPM 39117 9779 4890 3260 2445 1956 1397 or Fr 0.0012 0.0046 0.0092 0.0138 0.0184 0.0230 0.0322 CAST IRONS ≤ 19 HRc (256-384) Feed (ipm) 45.0 45.0 45.0 45.0 45.0 45.0 45.0 K Gray, Malleable, Ductile ≤ 260 Bhn 285 RPM 34838 8710 4355 2903 2177 1742 1244 or Fr 0.0011 0.0046 0.0092 0.0138 0.0184 0.0230 0.0321 ≤ 26 HRc (228-342) Feed (ipm) 40.0 40.0 40.0 40.0 40.0 40.0 40.0 ≤ 185 Bhn 275 RPM 33616 8404 4202 2801 2101 1681 1201 or Fr 0.0006 0.0026 0.0051 0.0077 0.0102 0.0128 0.0179 STAINLESS STEELS ≤ 9 HRc (220-330) Feed (ipm) 21.5 21.5 21.5 21.5 21.5 21.5 21.5 (FREE MACHINING) 303, 416, 420F, 430F, 440F ≤ 275 Bhn 170 RPM 20781 5195 2598 1732 1299 1039 742 or Fr 0.0005 0.0020 0.0040 0.0061 0.0081 0.0101 0.0141 ≤ 28 HRc (136-204) Feed (ipm) 10.5 10.5 10.5 10.5 10.5 10.5 10.5 M ≤ 275 Bhn 90 RPM 11002 2750 1375 917 688 550 393 or Fr 0.0005 0.0020 0.0040 0.0060 0.0080 0.0100 0.0140 STAINLESS STEELS ≤ 28 HRc (72-108) (DIFFICULT) Feed (ipm) 5.5 5.5 5.5 5.5 5.5 5.5 5.5 304, 316, 321, 13-8 PH, 65 RPM 7946 1986 993 662 497 397 284 15-5PH, 17-4 PH, Custom 450 ≤ 375 Bhn or Fr 0.0004 0.0018 0.0035 0.0053 0.0070 0.0088 0.0123 ≤ 40 HRc (52-78) Feed (ipm) 3.5 3.5 3.5 3.5 3.5 3.5 3.5 (continued on next page) 18 www.kyocera-sgstool.com

Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb

Каталог SGS высокопроизводительные фрезы для чистовой обработки Multi-carb Каталог SGS микроинструмент

Каталог SGS микроинструмент Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb